Struggling with tools dulling quickly during demanding cuts? Need a material that stays hard even when things get hot? High-speed steel offers a reliable answer for many machining challenges.

High-Speed Steel (HSS) is a type of tool steel alloy known for its exceptional hardness, wear resistance, and ability to maintain sharpness at high temperatures. This makes it perfect for cutting tools like drills, end mills, and taps used in CNC machining.

You've probably heard the term HSS thrown around in machine shops or seen it stamped on cutting tools. But what really makes it special, and why is it still so widely used despite newer materials emerging? Let's dig into the details and see why understanding HSS is crucial for anyone involved in manufacturing and machining. Understanding its properties helps you choose the right tools for the job.

What is HSS steel, fundamentally?

Finding the right tool material can feel confusing, right? Need something tough but also affordable for general cutting? HSS steel provides that balance for many everyday machining tasks.

HSS, or High-Speed Steel, is a specific group of alloy tool steels. Its main job is to be made into cutting tools. Key ingredients like tungsten, molybdenum, vanadium, and chromium give it unique properties.

Think of HSS as a workhorse material. It was a massive leap forward from the simple carbon steels used before it. Before HSS, tools would quickly overheat and lose their cutting edge if you tried to machine materials too fast. HSS changed the game because it could handle much higher temperatures generated during cutting without softening. This unique ability comes from its complex chemical makeup and the special heat treatment processes it undergoes. I remember when I first started; understanding the difference HSS made was a real eye-opener for improving efficiency on the shop floor.

Key Characteristics of HSS

HSS isn't just one thing; its properties define its usefulness:

- Hardness: It's hard enough to cut other metals effectively.

- Toughness1: It resists chipping or breaking, especially under impact or interrupted cuts. This is crucial for tools like drills.

- Wear Resistance2: It holds its sharp edge for a reasonable time.

- Red Hardness3: This is the defining feature – its ability to stay hard even when it gets red hot during high-speed cutting.

These characteristics make it incredibly versatile for creating various cutting tools.

Why is HSS called high-speed steel?

Ever wondered why they specifically call it "high-speed"? Does it just sound cool, or is there a real reason behind the name? The name directly reflects its game-changing advantage over older materials.

HSS earned its name because it allows machine tools to cut materials at significantly higher surface speeds compared to the high-carbon steel tools available before its invention. It maintains its hardness at elevated temperatures.

The term "high-speed" isn't just marketing fluff. Before HSS came along around the turn of the 20th century, tool steels were mostly simple high-carbon steels. If you tried to run a machine too fast, the friction would generate heat. This heat would quickly soften the carbon steel tool, making it lose its sharp cutting edge. Machinists had to run their machines slowly to prevent this. HSS, with its special alloying elements, fundamentally changed this limitation. It could withstand much higher temperatures (up to around 600°C or 1100°F) without losing its critical hardness. This property, often called "red hardness" or "hot hardness," allowed for dramatically increased cutting speeds, leading to faster production rates and improved efficiency.

In my experience, seeing the difference in cycle times achievable with HSS compared to older tool types really drives home why it got its name. It truly enabled a new era of faster manufacturing.

What elements make up HSS and give it its properties?

Confused about what makes one HSS grade different from another? Wondering how specific elements contribute to its performance? The secret lies in its carefully balanced alloy composition.

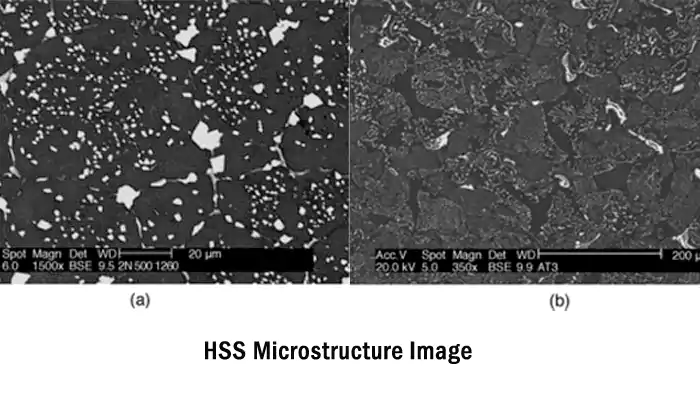

HSS is primarily an iron-based alloy mixed with significant amounts of carbon and other elements like Tungsten (W), Molybdenum (Mo), Vanadium (V), Chromium (Cr), and sometimes Cobalt (Co) to achieve desired properties.

The specific mix of these alloying elements is what gives HSS its remarkable characteristics. Carbon provides the basic hardness, but the real magic comes from the others. Tungsten and Molybdenum are key for red hardness and wear resistance. Vanadium forms very hard carbides, significantly boosting wear resistance and edge retention. Chromium increases hardenability (how deeply the steel hardens during heat treatment) and adds some corrosion resistance. Cobalt, often found in premium HSS grades (like M42), further enhances red hardness, allowing the tool to perform even better at higher temperatures and speeds, though it can sometimes reduce toughness slightly.

Here's a simplified look at the roles:

| Element | Primary Contribution | Effect |

|---|---|---|

| Carbon (C) | Hardness | Forms carbides with other elements |

| Tungsten (W) | Red Hardness, Wear Resist | Stable at high temperatures |

| Molybd. (Mo) | Red Hardness, Toughness | Often substitutes partially for Tungsten |

| Vanadium (V) | Wear Resistance | Forms very hard vanadium carbides |

| Chromium(Cr) | Hardenability4, Corrosion | Ensures deep hardening during heat treat |

| Cobalt (Co) | Enhanced Red Hardness | Allows for higher cutting speeds/temps |

Getting this balance right during manufacturing and heat treatment is critical. It’s how we get tools that are hard, tough, and resist heat effectively for demanding machining jobs.

Are there different types of High Speed Steel?

Noticed different codes like M2 or T1 on HSS tools? Wondering if they all perform the same way? There are indeed several types, each tailored for slightly different needs.

Yes, HSS is broadly classified into two main groups: Molybdenum-based (M-series) and Tungsten-based (T-series). Cobalt is often added to either type to further boost performance (e.g., M42).

The classification mainly depends on the primary alloying element used for achieving that critical hot hardness.

M-Series HSS

- Main Alloying Element: Molybdenum (Mo)5

- Characteristics: Generally have slightly better toughness and are often more cost-effective than T-series equivalents due to the lower cost of molybdenum compared to tungsten. They are the most common type used today.

- Examples: M1, M2, M7, M42 (contains Cobalt)

- My Take: In my shop, M2 HSS6 is a real staple for general-purpose drills and end mills. It offers a fantastic blend of performance and price. For tougher jobs or higher speeds, we step up to M42.

T-Series HSS

- Main Alloying Element: Tungsten (W)7

- Characteristics: Known for excellent red hardness and wear resistance. They were the original types developed but are less common now partly due to the higher cost and strategic importance of tungsten.

- Examples: T1, T15 (high Vanadium and Cobalt content)

- My Take: While less frequent, T-series, especially T15, still have their place for very demanding applications where maximum wear resistance and hot hardness are needed, though they can be more brittle than M-series.

The choice between types depends on the specific application, the material being cut, the machining operation (continuous vs. interrupted cuts), and budget constraints. Understanding these differences helps engineers like David specify the right tool for optimal results.

What are the advantages of high-speed steel?

Is HSS still relevant with materials like carbide available? Worried about tooling costs for your projects? HSS offers significant benefits, particularly in terms of value and versatility.

The main advantages of HSS include its excellent balance of toughness, wear resistance, and hardness at a relatively low cost. It's also easier to shape and sharpen compared to materials like solid carbide.

While carbide tools often offer higher cutting speeds and longer life in some applications, HSS holds its ground due to several key advantages:

- Toughness: HSS is generally much tougher than carbide. This means it's less prone to chipping or fracturing, especially in situations with vibration, older machines, less rigid setups, or interrupted cuts (like milling keyways). I've seen many expensive carbide tools shatter where a trusty HSS tool would just keep going.

- Cost-Effectiveness: HSS tools are significantly cheaper than their solid carbide counterparts. For general-purpose machining, job shops, or applications where tool breakage is a risk, HSS provides excellent value.

- Ease of Grinding/Sharpening: HSS can be resharpened relatively easily using standard grinding wheels, extending the tool's life and further reducing costs. Sharpening carbide requires specialized diamond grinding wheels.

- Versatility: It can be readily formed into complex tool geometries like drills, taps, form tools, and hobs.

- Good Performance: It offers very good performance across a wide range of materials and applications.

For many standard CNC machining tasks, particularly drilling and tapping, HSS remains the go-to choice because it hits that sweet spot of performance, toughness, and affordability.

Where is High Speed Steel used in CNC Machining?

Need specific examples of where HSS excels in a CNC environment? Trying to decide if HSS is right for your milling or drilling needs? HSS is the backbone for many common CNC cutting tools.

In CNC machining, HSS is widely used for making drills, taps, reamers, end mills, slitting saws, and form tools. Its toughness makes it particularly suitable for drilling and tapping operations.

HSS finds its place in numerous CNC applications due to its properties. Here are some primary areas:

Common HSS CNC Tools

- Drill Bits: This is arguably the most common application. The toughness of HSS is essential to withstand the stresses of drilling holes, especially in less-than-perfect conditions or with hand-held drills (though less common in pure CNC). HSS drills offer great value for making holes in various metals and plastics.

- Taps: Tapping (creating internal threads) requires significant toughness because the tool engages fully with the workpiece material and experiences high torque. HSS taps (like M2 or M7) are standard because they resist breaking in the hole, which can be a costly problem.

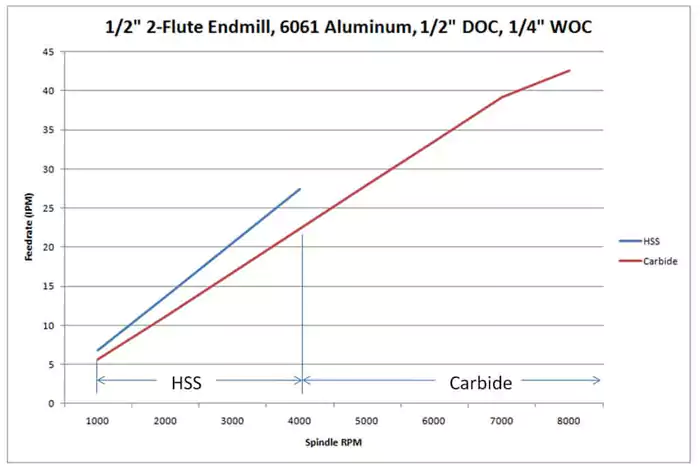

- End Mills: While carbide end mills dominate high-speed milling of harder materials, HSS end mills are still widely used for general-purpose milling, slotting, and profiling, especially in softer materials (like aluminum or mild steel) or on less rigid machines. Cobalt HSS (M42) offers a step up in performance.

- Reamers: For accurately sizing holes, HSS reamers provide a good balance of precision, finish, and cost.

- Other Tools: Saw blades, broaches, gear cutters (hobs), and custom form tools are also frequently made from HSS.

In my shop, we rely heavily on HSS for almost all our drilling and tapping needs. While we use carbide for high-performance milling, HSS end mills are indispensable for many standard jobs and setups where toughness is key.

How does High Speed Steel compare to other tool steels?

Confused between HSS, carbide, and plain carbon steel? Need to know when to choose one over the other? Understanding their key differences helps optimize tool selection for performance and cost.

HSS offers better hot hardness and wear resistance than high-carbon steels but less than cemented carbides. However, HSS is generally tougher and less expensive than carbide, making it ideal for specific applications.

Choosing the right cutting tool material involves trade-offs between hardness, toughness, heat resistance, and cost. Let's compare HSS to its main alternatives:

HSS vs. High-Carbon Steel

- Key Difference: Hot Hardness.

- Details: Simple high-carbon tool steels (like W1 or O1) harden well but soften rapidly at the temperatures generated during machining (around 200-250°C). HSS maintains its hardness up to much higher temperatures (around 600°C).

- Use Case: High-carbon steels are suitable for hand tools or very low-speed machining but unsuitable for modern production speeds. HSS enables much higher cutting speeds.

HSS vs. Cemented Carbide

- Key Difference: Hardness/Wear Resistance vs. Toughness/Cost.

- Details: Carbide tools (tungsten carbide particles cemented with cobalt) are significantly harder and more wear-resistant than HSS. They retain hardness at even higher temperatures, allowing for 3-10 times faster cutting speeds in ideal conditions. However, carbide is more brittle (less tough) and considerably more expensive.

- Use Case: Carbide excels in high-volume production, machining hard materials, and achieving fine finishes at high speeds on rigid machines. HSS is preferred for its toughness (drilling, tapping, interrupted cuts, less rigid setups) and lower cost.

HSS vs. Ceramics/CBN/PCD

- Key Difference: Extreme Performance vs. General Use.

- Details: Materials like Ceramics, Cubic Boron Nitride (CBN), and Polycrystalline Diamond (PCD) offer even higher hardness and heat resistance than carbide but are typically more specialized, brittle, and expensive.

- Use Case: These are used for very hard materials (CBN for hardened steel, PCD for non-ferrous like aluminum alloys) or extremely high speeds, often beyond the scope of typical HSS applications.

Here's a quick comparison table:

| Feature | High-Carbon Steel | High-Speed Steel (HSS) | Cemented Carbide | Ceramics/CBN/PCD |

|---|---|---|---|---|

| Hot Hardness | Low | Good | Very High | Extremely High |

| Toughness | Good | Excellent | Moderate | Low |

| Wear Resist. | Fair | Good | Very High | Extremely High |

| Cost | Low | Moderate | High | Very High |

| Typical Speed | Very Low | Moderate/High | High/Very High | Very High |

As a shop owner, matching the tool material to the job, machine capability, and budget is crucial. HSS remains a vital and cost-effective option in our toolkit.

Is high-speed steel the same as high-carbon steel?

Hearing "high-speed" and "high-carbon" might sound similar. Are they just different names for the same thing? No, they are distinct types of steel with very different capabilities.

No, high-speed steel (HSS) is not the same as high-carbon steel. While both contain carbon, HSS has significant additions of other alloying elements (like Tungsten, Molybdenum, Vanadium) that give it superior heat resistance.

This is a common point of confusion, but the difference is fundamental to their performance, especially in machining.

- High-Carbon Steel: This typically refers to simpler steel alloys containing roughly 0.6% to 1.25% carbon, with minimal amounts of other alloying elements. Think of older hand tools, files, or basic drill bits from decades ago. They can be hardened effectively but lose that hardness quickly when heated – they have poor "red hardness." Machining speeds must be kept low to avoid overheating the tool.

- High-Speed Steel (HSS): This is a much more complex alloy. It contains carbon (often in a similar range or slightly higher), but critically, it also includes substantial amounts of elements like tungsten, molybdenum, chromium, and vanadium. These additions allow HSS to retain its hardness and cutting edge even when it gets very hot during high-speed cutting operations.

Think of it like this: High-carbon steel is like an athlete who is strong but tires quickly in the heat. High-speed steel is like an endurance athlete specifically trained to perform well even under hot, demanding conditions. The alloying elements in HSS are the key differentiator, enabling the "high-speed" capability that gives it its name.

Why Choose Allied Metal for CNC Machining Needs?

Looking for a reliable partner for your custom CNC parts? Need expertise in material selection and efficient production? Allied Metal understands the needs of engineers like you.

Allied Metal combines hands-on machining experience with a focus on quality, efficiency, and clear communication. We understand material properties like HSS and help you achieve precise parts cost-effectively.

As someone who built their business from the ground up in the CNC world, I know the challenges engineers like David face. You need more than just a shop that can cut metal; you need a partner who understands your designs, respects tolerances, communicates clearly, and delivers consistent quality on time.

What We Offer:

- Material Expertise: We work with a wide range of materials daily, from standard aluminum and steels (including parts requiring HSS tooling for specific features) to specialized alloys and plastics. We can advise on material selection based on your application needs.

- Precision Machining: Our capabilities cover complex geometries and tight tolerances, ensuring your parts meet exact specifications outlined in your CAD drawings.

- Efficiency Focus: We utilize techniques like optimized tool paths and efficient setups to minimize cycle times and provide competitive pricing for both prototypes and production runs.

- Clear Communication & Quoting: We provide fast, accurate quotes based on your drawings and maintain open communication throughout the manufacturing process.

- Quality Assurance: Rigorous inspection ensures every part meets your requirements.

- Confidentiality: We understand the importance of protecting your proprietary designs and operate with strict confidentiality protocols.

My journey from machinist to business owner was built on understanding these details. At Allied Metal, we bring that practical experience to help your projects succeed, leveraging the right tools and materials, like HSS where appropriate, to get the job done right.

Conclusion

In summary, High-Speed Steel (HSS) remains a vital tool material in CNC machining due to its excellent toughness, good heat resistance, and cost-effectiveness, especially for drilling and tapping operations.

Footnotes:

-

Learning about toughness can help you appreciate its role in tool performance and longevity, especially under stress. ↩

-

Understanding wear resistance is essential for selecting the right materials for cutting tools, ensuring durability and performance. ↩

-

Exploring red hardness will provide insights into why HSS is preferred for high-speed applications, enhancing tool longevity. ↩

-

Learning about Hardenability is essential for optimizing heat treatment processes, ensuring materials achieve desired strength and durability. ↩

-

Explore the advantages of Molybdenum in HSS to understand its cost-effectiveness and toughness compared to other alloys. ↩

-

Discover why M2 HSS is favored for its performance and cost-effectiveness, making it a staple in many workshops. ↩

-

Learn about Tungsten's role in enhancing wear resistance and red hardness in HSS, crucial for demanding machining tasks. ↩