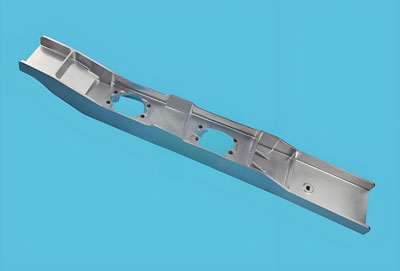

1. Plane type parts:

The machining surface of these parts is parallel or perpendicular to the horizontal plane, usually need two-axis linkage to process, is the simplest CNC milling parts.

The Professional CNC Machining Supplier

The Professional CNC Machining Supplier

CNC milling is one of the backbone technologies of precision manufacturing. Whether you’re machining small aluminum housings or large aerospace brackets, it offers accuracy, repeatability, and speed that traditional manual milling can’t match.

CNC Milling is a type of machining that utilizes computer program control. With CNC Milling, operators can accurately cut, punch, and mold a variety of materials, commonly used in metal and plastic processing.

By automating tool movement and optimizing cutting paths, CNC milling reduces human error, material waste, and cycle time. Modern systems even monitor tool wear and automatically adjust speeds and feeds to maintain part accuracy.

There are several main types of CNC milling machines:

The main features of CNC milling include high precision, high efficiency and a high degree of automation. This makes it particularly popular in mass production. Its advantages are:

Common CNC milling methods include:

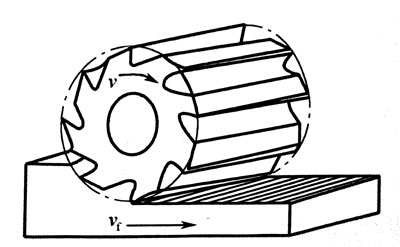

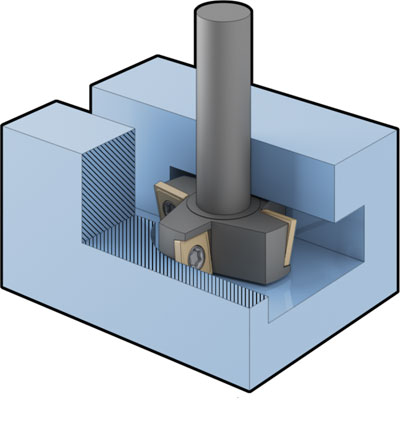

1. Planar Milling: used to machine flat surfaces.

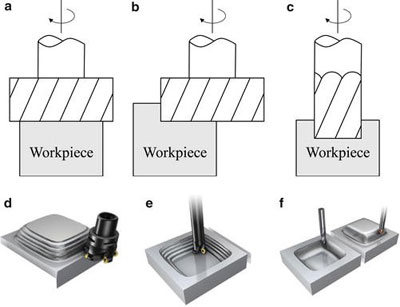

2. Contour milling: cutting along specific contours to form complex shapes.

3. Recess Milling: Used to make grooves or concave structures.

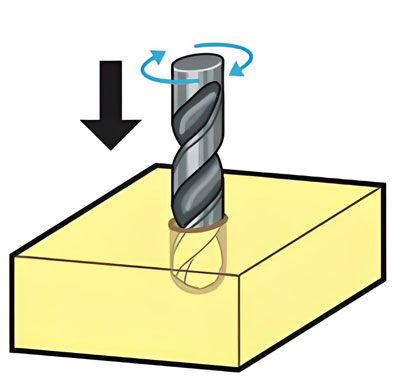

4. Drill Milling: Specialized for drilling holes in workpieces, suitable for making holes of various sizes.

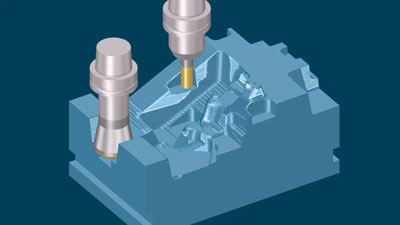

5. Three-dimensional milling: used to process complex three-dimensional shapes on the workpiece, suitable for making complex molds and parts.

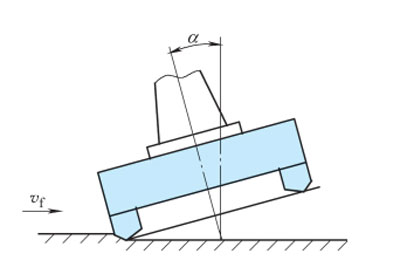

6. Inclined Milling: cutting the workpiece by changing the angle of the tool, suitable for machining that requires inclined surfaces or beveled edges.

7. Edge milling: Mainly used to remove excess material from the edges of the workpiece, ensuring a smooth and accurately dimensioned part.

These milling methods combined with different machining needs can help manufacturers produce more diverse and complex parts. If you need a professional CNC milling processing service provider, then Allied Metal will be a good choice.

All the theory on DFM is great, but let’s talk about a real-world part where these principles make the difference between success and a scrap bin full of expensive metal. This is the kind of “must-know” detail that I share with engineers.

We had a client in the heavy equipment industry who needed a custom hydraulic manifold block. This is a part that looks simple—just a brick of aluminum—but it’s incredibly complex. It manages high-pressure fluid for a hydraulic system, and the internal features are what make or break it.

The Challenge: The part was a solid block of 6061-T6 Aluminum. The main challenges were not just the 3D-milled pockets on the outside, but the deep, intersecting fluid channels inside and, most importantly, the main sealing face. If this face wasn’t perfectly flat, the high-pressure (we’re talking 3000 PSI) fluid would find a way out, and the whole machine would fail.

Here’s the “must-know” secret: You can’t just run a face mill over it once and call it a day. When we machined the deep pockets on the other side of the block, we removed over 60% of the material. This releases the internal stress in the aluminum, and the whole part will warp—like a potato chip.

Our process had to account for this:

The Result: By using this multi-stage process, we delivered a batch of manifolds that were 100% stable and passed all the client’s high-pressure leak tests. A less experienced shop would have chased that flatness tolerance all day, scrapping parts and breaking tools. The “must-know” part of milling isn’t just how to cut, it’s how to control the material.

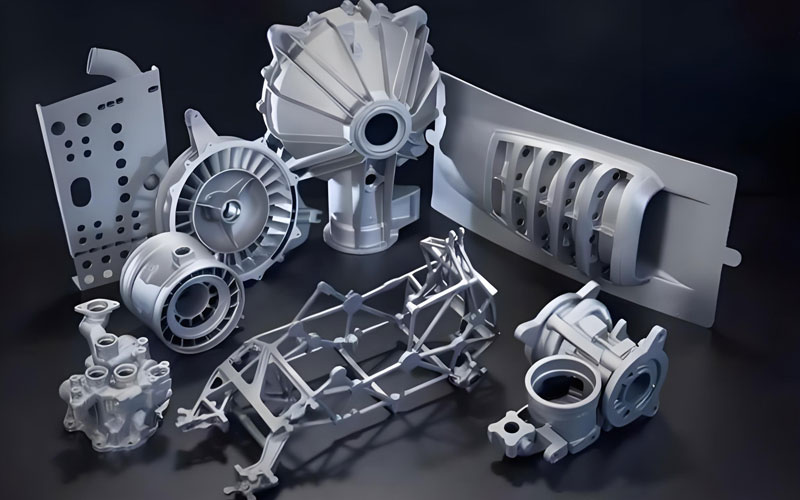

CNC milling can produce many types of parts, mainly including the following categories:

The machining surface of these parts is parallel or perpendicular to the horizontal plane, usually need two-axis linkage to process, is the simplest CNC milling parts.

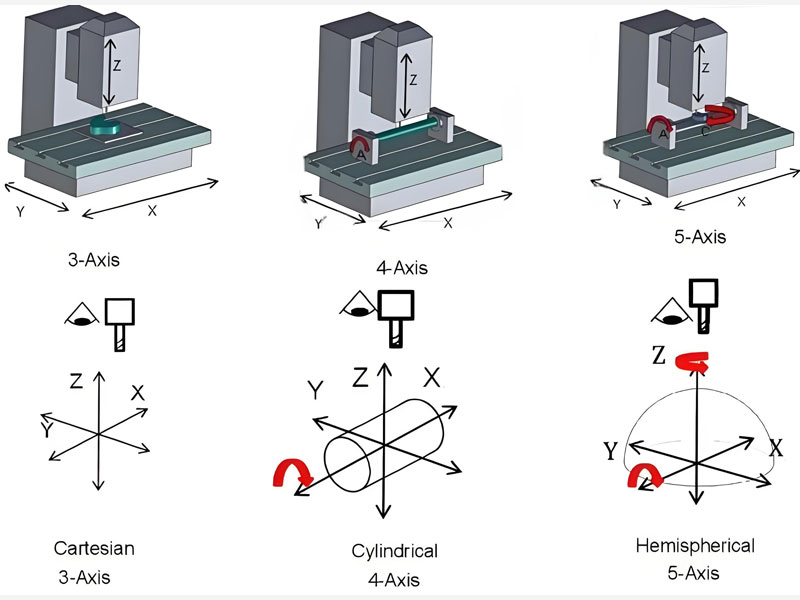

The machining surface of these parts has a variable angle with the horizontal plane, and cannot be expanded into a flat surface. Usually use four-axis or five-axis milling machine processing, you can also use three-axis approximate processing.

The machining surface of this type of parts is space surface, such as molds and propellers. The milling cutter is in point contact with the surface during machining, and is usually machined with a ball-end cutter on a 3-axis milling machine. For complex surfaces, a 4-axis or 5-axis milling machine may be required.

These parts have complex curved contours and are usually designed based on mathematical models. During machining, the milling cutter maintains point contact with the machined surface, which needs to be programmed through the CNC.

CNC milling machines can also machine various types of mechanical parts (such as gears, bearings, pump bodies, etc.), aerospace parts, automotive parts, mold parts, electronic parts (such as circuit boards) and medical devices.

The advantages of CNC milling include high precision, high efficiency, strong adaptability and programmability, which are suitable for the processing of various complex structural parts.

Whether you’re sourcing one prototype or 10,000 production parts, understanding CNC milling helps you evaluate suppliers and part designs with confidence.

If you need reliable machining for tight-tolerance components, Allied Metal’s experienced team can help you achieve that balance of accuracy, cost-efficiency, and turnaround time.

We use cookies to ensure that we provide you with the best possible experience on our website.