Editor's Note: Last updated on 2025-10-17 11:26:37 Friday

Confused about copper, brass, and bronze for your parts? Choosing the wrong one leads to performance issues or higher costs. Understanding their unique traits ensures the best fit for your CNC machined components.

For outstanding electrical and thermal conductivity, copper is best. For a good balance of strength, corrosion resistance, and machinability, choose brass. For high strength, wear resistance, and excellent corrosion resistance, bronze is the top choice.

Selecting the right red metal involves more than just these highlights. Factors like cost, specific environmental conditions, and the stresses the part will endure are key. As someone who's machined all three extensively at Allied Metal, I know picking the right one is critical. Let's delve into how to tell them apart and when to use each.

How can you tell if it's copper or bronze or brass?

Got scrap metal or unlabeled stock in the workshop? Guessing between copper, brass, or bronze risks using the wrong material and ruining parts. Simple visual cues and basic tests can help you identify them correctly.

Distinguish them mainly by color: Copper is reddish-pink, brass is typically yellowish (like a trumpet), and bronze is generally reddish-brown or golden-brown. None are strongly magnetic unless contaminated with iron. Patina color and relative hardness can also offer clues.

Just relying on memory can be tricky, especially with different alloys looking similar. When we get new stock at the shop, it's labeled, but leftover pieces or salvaged parts need identification. Here are the common ways we tell them apart:

Visual and Simple Tests

- Color: This is usually the most immediate indicator.

- Copper: Has a distinct reddish or pinkish-orange hue when clean. Think of a new penny or electrical wire.

- Brass: An alloy of copper and zinc. Its color ranges from pale yellow to reddish-yellow, depending on the zinc content1. Higher zinc means paler yellow. Common C360 brass2 is quite yellow.

- Bronze: An alloy of copper primarily with tin (but sometimes other elements like aluminum or silicon). It typically has a duller, browner, or more golden hue compared to copper's pinkish tone. Think of statues or old bells.

- Magnet Test: Generally, copper, brass, and bronze are non-magnetic3. If a magnet sticks strongly, it's likely steel or contains significant iron inclusions. A weak attraction might occur in some specific alloys (like nickel-aluminum bronze), but typical brass and copper alloys won't attract a magnet.

- Patina (Oxidation Color): How the metal looks when tarnished can be a clue.

- Copper and many brasses tend to oxidize to a green color over time (like the Statue of Liberty).

- Bronze often develops a darker brown or greenish-brown patina.

- Relative Hardness4 (Subjective): While not precise without testing equipment, you can sometimes get a feel. Pure copper is quite soft and easily scratched or bent. Brass is generally harder than copper. Bronze alloys are often harder and more brittle than brass.

Identification Summary Table:

| Feature | Copper | Brass | Bronze |

|---|---|---|---|

| Typical Color | Reddish-Pink | Yellowish | Reddish-Brown/Golden-Brown |

| Magnetic? | No | No | No (Generally) |

| Patina | Green | Green/Brownish | Dark Brown/Greenish-Brown |

| Hardness | Soft | Harder than Copper | Often Hardest of the three |

Always confirm with specifications if possible, but these visual and simple tests are great starting points for identification on the shop floor.

Why is bronze preferred to copper?

Copper is a fantastic metal, but it's not always the right choice. Using soft copper where strength or wear resistance is needed leads to early failure. Bronze is often preferred for its superior toughness and durability in demanding situations.

Bronze is chosen over copper when higher mechanical strength, better wear resistance (vital for bearings, bushings), and superior corrosion resistance (especially against saltwater) are required. Copper is softer and less durable for these demanding structural or high-wear applications.

Think about the job the part has to do. Copper conducts electricity like a champ, but ask it to act as a heavy-duty gear or survive in seawater, and it struggles. That's where bronze shines. We often machine bronze for marine components and mechanical wear parts.

Key Advantages of Bronze Over Copper:

- Strength and Hardness: Bronze alloys, primarily copper mixed with tin, are significantly harder and stronger than pure copper. Adding tin creates a tougher material that can withstand higher loads and resist deformation. This makes bronze suitable for structural applications, gears, and components under mechanical stress where copper would bend or break.

- Wear Resistance: Bronze exhibits excellent resistance to wear and friction, especially certain types like phosphor bronze or aluminum bronze. This property makes it ideal for components that slide or rub against other parts, such as:

- Bearings and Bushings: Bronze provides a durable, low-friction surface.

- Wear Plates: Used where components slide against each other.

- Valve Guides: Need to withstand constant movement.

Copper, being much softer, would wear away quickly in these applications.

- Corrosion Resistance: While copper has good corrosion resistance, bronze alloys (especially those with tin or aluminum) are generally superior, particularly in marine environments. They resist corrosion from saltwater and many chemicals better than pure copper does. This is why bronze is heavily used for ship propellers, underwater fittings, and marine hardware.

- Lower Metal-on-Metal Friction: Some bronze alloys have lower coefficients of friction against steel compared to copper, which is beneficial in bearing applications.

Bronze vs. Copper for Tough Jobs:

| Property | Copper | Bronze (Typical Tin Bronze) | Why Bronze is Preferred Here |

|---|---|---|---|

| Tensile Strength | Lower | Higher | Withstands greater pulling forces |

| Hardness | Soft | Harder | Resists scratching and indentation |

| Wear Resistance | Poor | Excellent | Lasts longer in sliding contact |

| Marine Corrosion | Good | Excellent | Survives better in saltwater |

| Suitability for Gears | No | Yes | Strong enough to handle tooth loads |

So, while copper has its place, bronze steps in when the application demands toughness, wear resistance, or superior performance in corrosive environments.

Why is copper better than brass?

Brass is strong, machinable, and looks good, so why ever choose pure copper? Using brass when you need top electrical or thermal performance limits efficiency. Copper is superior when moving electricity or heat is the absolute main goal.

Copper is better than brass primarily for its significantly higher electrical and thermal conductivity—nearly twice that of many common brasses. It's also more ductile (easier to bend and form) and has natural antimicrobial properties.

When a customer needs parts for electrical connectors, heat exchangers, or wiring, copper is almost always the first choice. Brass, being an alloy of copper and zinc, simply can't compete in transferring energy efficiently. The zinc atoms disrupt the flow of electrons and heat compared to pure copper's structure.

Key Advantages of Copper Over Brass:

- Electrical Conductivity5: This is copper's superpower. It's the standard by which other conductors are measured (100% IACS - International Annealed Copper Standard). Most brass alloys have conductivity ratings between 25% and 50% IACS. This makes copper essential for:

- Electrical Wiring and Cables

- Busbars and Connectors

- Electromagnets and Motor Windings

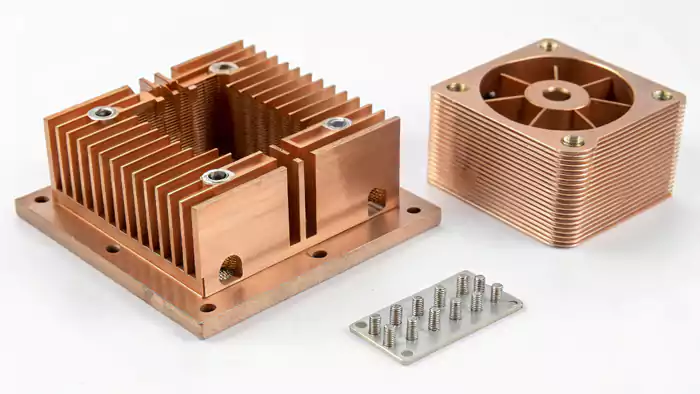

- Thermal Conductivity: Copper is also exceptional at transferring heat, second only to silver. This makes it ideal for:

- Heat Sinks for electronics cooling

- Heat Exchangers (like radiators or HVAC coils)

- High-quality Cookware bases

Brass conducts heat better than steel but significantly less effectively than copper.

- Ductility and Formability: Pure copper is very ductile, meaning it can be easily drawn into wires, bent into complex shapes (like plumbing tubes), or hammered thin without breaking. Brass is generally less ductile than copper, especially high-zinc brasses which can become brittle.

- Antimicrobial Properties: Copper and its alloys naturally kill certain bacteria, viruses, and fungi on contact. This "contact killing" makes copper useful for touch surfaces in hospitals or public places to reduce germ transmission, though brass also shares this property to some extent.

Copper vs. Brass for Energy Transfer:

| Property | Copper (Pure) | Brass (e.g., C360) | Why Copper is Preferred Here |

|---|---|---|---|

| Electrical Conductivity | Excellent (~100% IACS) | Good (~26% IACS) | Maximum electrical efficiency |

| Thermal Conductivity | Excellent (~400 W/m·K) | Good (~120 W/m·K) | Maximum heat transfer |

| Ductility (Formability) | Very High | Moderate to Good | Easier to form complex shapes |

| Antimicrobial Action | Strong | Present, often weaker | Better for hygiene applications |

| Strength | Lower | Higher | Brass is better here |

So, if your part's main job involves conducting electricity or heat efficiently, or if it needs to be easily formed into intricate shapes, copper is the superior choice over brass.

Real-World Application: Marine Valve Component Comparison

Here's a practical example from our shop that perfectly illustrates how material selection impacts real parts across multiple dimensions:

We recently worked with a marine equipment manufacturer redesigning a critical valve component for saltwater cooling systems. The production manager needed 500 units with optimal performance across corrosion resistance, machinability, and cost.

Part Requirements:

- Operating Environment: Saltwater immersion, 5+ year service life

- Pressure Rating: 150 PSI minimum

- Wear Resistance: 50,000+ cycles without failure

- Machining Tolerance: ±0.001" on critical sealing surfaces

- Cost Target: Under $45 per part in production quantities

Material Evaluation Process:

The design engineer initially specified C11000 copper for its corrosion resistance, but our production team raised concerns about wear performance and material cost.

We prototyped the component in three different materials to compare performance:

Test Results Comparison:

| Material | C11000 Copper | C36000 Brass | C93200 Bronze |

|---|---|---|---|

| Material Cost/Part | $38.50 | $22.80 | $31.20 |

| Machining Time | 18 minutes | 9 minutes | 14 minutes |

| Surface Finish (Ra) | 32 μin | 16 μin | 25 μin |

| Corrosion Test | Moderate pitting after 90 days | Surface tarnishing after 60 days | Minimal corrosion after 180 days |

| Wear Test Cycles | 28,500 cycles failure | 42,000 cycles failure | 65,000+ cycles (still operational) |

| Reject Rate | 12% (soft material issues) | 3% (excellent machinability) | 5% (consistent quality) |

Final Selection & Production Outcome:

After reviewing the test data, the procurement manager approved C93200 bearing bronze despite its higher material cost. The decision was based on:

- Total Cost Savings: Bronze provided the lowest total cost per functional unit when considering replacement frequency and maintenance downtime

- Performance: Exceeded all wear and corrosion requirements by significant margins

- Reliability: Reduced warranty claims and field failures by 78% compared to previous copper versions

"The bronze components have been in service for over two years now with zero failures. Sometimes the higher upfront material cost pays for itself many times over in reduced maintenance and downtime." - Senior Machinist

Ready to optimize your material selection? Contact our engineering team for a free material analysis and let our 20+ years of copper alloy machining experience work for your project.

What is the cost difference between copper, brass and bronze?

Material costs significantly impact project budgets. Not knowing the relative prices of copper, brass, and bronze can lead to costly surprises down the road. Understanding their general cost ranking helps in planning and material selection.

Generally, copper is the most expensive due to the high cost of pure copper metal. Bronze is typically second, as alloying elements like tin can be costly. Brass is often the least expensive because its main alloying element, zinc, is cheaper than tin.

When quoting jobs for clients like Jacky, material cost is a major factor. While market prices fluctuate daily based on the London Metal Exchange (LME) and supply/demand, a general hierarchy usually holds true. Remember, this is for the raw material; machining costs can also vary.

Factors Influencing Cost:

- Base Metal Prices: Copper (Cu) is a globally traded commodity with a relatively high price compared to zinc (Zn) or even tin (Sn) sometimes. Since all three metals are copper-based, the copper content is a primary cost driver.

- Alloying Elements:

- Brass (Cu + Zn): Zinc is significantly cheaper than copper and tin. Therefore, brass alloys generally have the lowest material cost among the three.

- Bronze (Cu + Sn, Al, Si, etc.): Tin is often more expensive than zinc, making traditional tin bronzes more costly than brass. Other alloying elements like aluminum or silicon also add to the cost. Specialized bronze alloys can be quite expensive.

- Copper: High-purity copper commands the highest price per pound or kilogram.

- Alloy Complexity and Processing: More complex alloys or those requiring specialized processing might have higher costs beyond just the raw materials.

- Market Fluctuations: Prices for copper, zinc, and tin can change daily based on global markets, affecting the final cost of the alloys.

- Form Factor: The form of the material (e.g., sheet, plate, bar, tube) and the quantity purchased also impact the price per unit weight.

General Cost Ranking (Material Only):

- Most Expensive: Copper (especially high purity grades)

- Mid-Range: Bronze (can vary widely based on alloy type)

- Least Expensive: Brass (most common alloys)

Important Note: While brass material might be cheapest, its excellent machinability (especially free-cutting brass like C36000) can sometimes lead to lower overall part costs compared to harder-to-machine copper or some bronzes, because machining time is reduced. Always consider both material cost and manufacturing cost.

How do I choose the right metal material for my project needs?

Facing the choice between copper, brass, and bronze can feel daunting. Picking based just on looks or assuming one is always 'better' can compromise your design's function or budget. A systematic approach matching material strengths to project needs ensures success.

Choose based on the primary requirement: Copper for top conductivity (electrical/thermal). Brass for good machinability, moderate strength, and corrosion resistance at a reasonable cost. Bronze for high strength, wear resistance, and excellent corrosion resistance, especially in marine environments.

When a designer comes to us with a project, the first question is always "What does this part need to do?". The function dictates the material. You need to prioritize the most critical properties for your specific application.

Decision Framework: Matching Properties to Needs

Here's a simple guide to help you choose:

- Is Electrical or Thermal Conductivity Paramount?

- Yes: Copper is the clear choice. Nothing else in this group comes close. (e.g., Busbars, heat sinks, wiring terminals).

- No: Consider Brass or Bronze.

- Is High Strength or Wear Resistance Critical?

- Yes: Bronze is likely the best option, especially for bearings, bushings, gears, or parts under heavy load or sliding friction. Specific bronze alloys offer exceptional wear characteristics.

- No: Consider Copper or Brass if strength requirements are moderate.

- Is Excellent Corrosion Resistance Needed, Especially Saltwater?

- Yes: Bronze (especially tin or aluminum bronzes) generally offers the best marine corrosion resistance.

- Moderate Resistance OK? Brass offers good general corrosion resistance, better than many steels. Copper is also good but may tarnish more easily.

- Is Machinability a Major Factor (for complex parts or high volume)?

- Yes: Brass (particularly C360 free-cutting brass) offers excellent machinability, potentially lowering cycle times and costs.

- Less Critical: Copper and Bronze can be machined effectively, but often require different speeds, feeds, and potentially more tool wear than brass.

- Is Cost a Primary Constraint?

- Yes: Brass is typically the most budget-friendly option for the raw material.

- Performance Justifies Cost? Copper and Bronze are more expensive but necessary when their specific properties are required.

- Is Appearance Important?

- Reddish-Pink: Copper

- Yellowish: Brass

- Reddish-Brown/Golden: Bronze

(Remember that appearance can be altered with plating or finishing).

Example Scenario for the customer:

- Designing electrical contacts for a consumer electronic device? -> Copper (Conductivity is key).

- Designing a sturdy, corrosion-resistant fitting for outdoor use? -> Brass (Good balance of properties and cost).

- Designing a bushing for a rotating shaft in industrial equipment? -> Bronze (Wear resistance is critical).

By prioritizing the most critical requirements for your project, you can confidently select the most suitable metal from these three excellent options.

Conclusion

Copper excels in conductivity, making it ideal for electrical and thermal uses. Brass offers a great balance of machinability, cost, and strength. Bronze provides superior strength, wear, and corrosion resistance.

Footnotes:

-

Discover how varying zinc content influences the color of brass, enhancing your knowledge of material properties. ↩

-

Explore this link to understand the unique properties and applications of C360 brass, a popular alloy in various industries. ↩

-

Understanding non-magnetic metals can help you identify materials in various applications, enhancing your knowledge in metallurgy. ↩

-

Learning about the relative hardness of these metals can aid in selecting the right material for your projects, ensuring durability and performance. ↩

-

Understanding electrical conductivity can help you choose the right materials for your projects, enhancing efficiency and performance. ↩