Editor's Note: Last updated on 2025-10-17 10:50:51 Friday

Struggling to find plastics that won't warp or fail under heat? Using the wrong material leads to costly part failures. Choosing the right heat-resistant plastic for CNC machining ensures your components perform reliably.

For CNC machining, top heat-resistant plastics include PEEK, PTFE, Polyimide (PI), and Ultem (PEI). These materials maintain their structure and properties at high temperatures, making them suitable for demanding applications where standard plastics would fail.

Selecting the ideal material goes beyond just temperature ratings. Machinability, chemical resistance, and cost are also vital factors. Let's dive deeper into the specifics to help you make the best choice for your project. Read on to explore the options.

What types of heat resistant plastics are available?

Confused by all the plastic options claiming heat resistance? Choosing incorrectly can compromise your project's integrity. Let's explore the main types available for high-temperature CNC machining needs.

Common heat-resistant plastics for CNC work include PEEK, PTFE (Teflon), Polyimide (PI), PEI (Ultem), PPS, and PAI. Each offers a unique profile of temperature resistance, mechanical strength, chemical compatibility, and machinability.

Understanding the different families of heat-resistant plastics1 is the first step. They aren't all created equal, and the best choice depends heavily on the specific demands of your application. I've worked with many of these over the years, and knowing their characteristics is key.

Let's break down some of the most common types used in CNC machining:

Key High-Temperature Plastics

- PEEK (Polyether Ether Ketone)2: This is a real workhorse in demanding environments. It offers excellent mechanical strength, stiffness, and resistance to chemicals and wear, alongside high-temperature performance. It's often a go-to when you need a balance of properties. Machining PEEK requires care due to its toughness, but it yields precise parts.

- PTFE (Polytetrafluoroethylene)3: You probably know this as Teflon. Its standout feature is incredible chemical inertness and a very low friction coefficient. It also handles high temperatures well. However, it's mechanically weak compared to PEEK or Ultem, so it's not ideal for load-bearing parts. It machines easily but can be 'gummy'.

- PI (Polyimide)4: When you need top-tier heat resistance, PI is often the answer. Certain grades can handle extremely high temperatures, exceeding many other polymers. It also offers good mechanical properties and wear resistance. However, it can be challenging and expensive to machine.

- PEI (Polyetherimide - Ultem): Ultem provides a great combination of high heat resistance, rigidity, strength, and broad chemical resistance. It's often seen as a more cost-effective alternative to PEEK in some applications. It machines relatively well, similar to PEEK.

- PPS (Polyphenylene Sulfide): Known for its excellent chemical resistance, dimensional stability, and good performance at elevated temperatures. It sits below PEEK and PI in terms of absolute heat resistance but is a solid choice for many industrial uses.

- PAI (Polyamide-imide - Torlon): This material boasts exceptional strength, stiffness, and wear resistance at high temperatures, sometimes outperforming PEEK in specific conditions. It's often used for severe wear applications but can be more difficult to machine.

Here's a quick comparison table:

| Feature | PEEK | PTFE (Teflon) | PI (Polyimide) | PEI (Ultem) |

|---|---|---|---|---|

| Max Continuous Temp | ~480°F (250°C) | ~500°F (260°C) | ~500°F+ (260°C+) | ~340°F (170°C) |

| Strength | Very High | Low | High | High |

| Chemical Resistance | Excellent | Exceptional | Good | Very Good |

| Machinability | Moderate | Easy (but 'gummy') | Difficult | Moderate |

| Relative Cost | High | Moderate | Very High | High |

Choosing involves balancing these factors against your project's needs and budget.

Real-World Application: Aerospace Sensor Mounting Bracket

Here's a case from our shop that demonstrates how material selection plays out in practice for high-temperature applications:

We recently manufactured a critical sensor mounting bracket for an aerospace testing rig. The design engineer needed a solution that could withstand repeated thermal cycling from -65°F to 400°F (-54°C to 204°C) while maintaining precise alignment of optical components.

Part Requirements:

- Operating Temperature Range: -65°F to 400°F (-54°C to 204°C)

- Thermal Cycling: 500+ cycles without deformation

- Dimensional Stability: ±0.001" per inch over full temperature range

- Vibration Resistance: Withstand 15G RMS random vibration

- Weight: Under 85 grams

- Chemical Exposure: Hydraulic fluid and jet fuel vapors

Material Selection Process:

The production manager initially considered aluminum 7075 for its strength-to-weight ratio, but thermal expansion concerns ruled it out. The design engineer then proposed titanium, but cost and machining complexity were prohibitive.

After reviewing material performance data and consulting with our senior machinist, we recommended PEEK 450G (30% glass-filled) for its optimal balance of thermal stability, strength, and manufacturability.

Final Specifications & Machining Results:

- Material: PEEK 450G (30% glass fiber reinforced)

- Machining Process: 4-axis milling with specialized carbide tooling

- Critical Dimensions: All mounting features held to ±0.0005"

- Surface Finish: 32 μin Ra achieved on optical mounting surfaces

- Thermal Performance: Verified stable through 650 thermal cycles

- Weight: 78 grams - 8% below target

- Production Cost: $142 per part - 40% lower than titanium alternative

- Lead Time: 4 weeks for 45-piece production run

The quality team noted that using compressed air cooling and sharp carbide end mills prevented glass fiber pull-out and maintained dimensional stability. This material selection saved approximately $12,000 in production costs while exceeding all performance requirements.

Which plastic is most heat-resistant?

Need the absolute highest temperature performance? Pushing the limits requires identifying the plastic that can take the most heat without degrading. Let's pinpoint the top performers.

Polyimide (PI) generally offers the highest heat resistance among commonly machinable plastics, with some grades capable of continuous use above 500°F (260°C) and withstanding even higher temperatures for short periods. High-temp PEEK grades and PEI (Ultem) also offer excellent performance.

When we talk about the "most" heat-resistant, it's important to be specific. Are we talking about continuous operation over thousands of hours, or brief exposure to extreme heat? Different materials excel in different scenarios.

Understanding Temperature Ratings

- Continuous Service Temperature5: This is the maximum temperature a material can withstand constantly without significant degradation of its properties over its expected service life. This is often the most critical number for long-term applications.

- Heat Deflection Temperature (HDT)6: This measures the temperature at which a material deforms under a specific load. It indicates short-term heat resistance and stiffness at temperature but isn't the same as continuous service temperature.

- Glass Transition Temperature (Tg)7: For amorphous plastics like PEI, this is the temperature where the material transitions from a rigid state to a more rubbery state. Properties change significantly above Tg.

- Melting Point (Tm)8: For semi-crystalline plastics like PEEK and PTFE, this is the temperature where the crystalline structure breaks down, and the material melts. They typically retain useful properties closer to their Tm than amorphous plastics do to their Tg.

The Top Contenders

Based on continuous service temperature, here's how the leaders stack up:

- Polyimide (PI): Often considered the king of heat resistance. Grades like Vespel® can operate continuously above 500°F (260°C), with some formulations pushing towards 550°F (290°C) or higher for short durations. They don't melt like thermoplastics; they eventually char at extreme temperatures.

- PTFE: While its mechanical properties aren't great, its thermal stability is excellent up to around 500°F (260°C).

- PEEK: Standard grades handle continuous use up to about 480°F (250°C). Filled grades (e.g., glass or carbon fiber) often have slightly higher HDT but similar continuous use limits.

- PAI (Torlon): Offers strength retention at high temperatures, often usable up to around 500°F (260°C).

- PEI (Ultem): Standard grades are typically rated for continuous use around 340°F (170°C), which is excellent but lower than PI or PEEK.

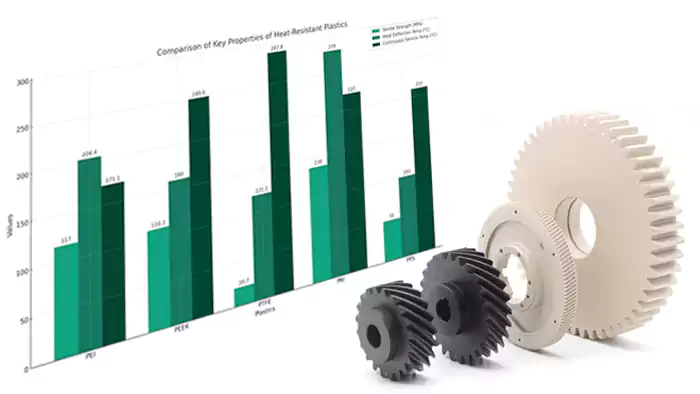

Comparison of Top Heat-Resistant Plastics:

| Material | Typical Max Continuous Temp | Key Advantage | Key Disadvantage |

|---|---|---|---|

| Polyimide (PI) | >500°F (260°C+) | Highest Temperature Resistance | High Cost, Difficult Machining |

| PTFE | ~500°F (260°C) | Chemical Inertness, Low Friction | Low Mechanical Strength |

| PAI (Torlon) | ~500°F (260°C) | High Strength at Temp | Difficult Machining, Cost |

| PEEK | ~480°F (250°C) | Balanced Properties, Strength | High Cost |

| PEI (Ultem) | ~340°F (170°C) | Good Balance, Lower Cost (vs PI/PEEK) | Lower Temp Limit (vs PI/PEEK) |

So, while Polyimide often takes the crown for pure temperature resistance, factors like cost, machinability, and specific mechanical needs might lead you to PEEK, PAI, or even PTFE depending on the application.

How can you tell if plastic is heat-resistant?

Got a plastic part or material stock, but unsure of its heat tolerance? Using it in a high-temp application without knowing could lead to failure. Let's look at how to identify heat-resistant plastics.

The most reliable way is checking the manufacturer's datasheet for specifications like Continuous Service Temperature or Heat Deflection Temperature (HDT). Material identification codes molded onto parts (e.g., >PEEK<) can also help, but datasheets provide definitive grade-specific info.

Just looking at a piece of plastic won't tell you its temperature rating. High-performance plastics often look similar to standard ones. I always rely on documentation – guesswork is too risky when heat is involved.

Here's a breakdown of how to determine heat resistance:

1. Check the Datasheet

This is the gold standard. If you know the specific plastic grade (e.g., "Ultem 1000" or "PEEK 450G"), you can find its technical datasheet online from the manufacturer or supplier (like Quadrant EPP, Ensinger, DuPont, Sabic). Look for these key properties:

- Continuous Service Temperature / Maximum Operating Temperature: This tells you the temperature the plastic can handle long-term.

- Heat Deflection Temperature (HDT) / Deflection Temperature Under Load (DTUL): Indicates stiffness at elevated temperatures under load. Useful for structural parts but represents short-term capability.

- Glass Transition Temperature (Tg): Important for amorphous plastics (like PEI, PC). Properties change above this temperature.

- Melting Temperature (Tm): Relevant for semi-crystalline plastics (like PEEK, PTFE, Nylon). The material melts above this point.

2. Look for Material Identification Codes

Many molded or sometimes extruded plastic parts have identification codes stamped or molded into them, usually surrounded by ">" and "<" symbols (e.g., >PEEK<, >PA66-GF30<, >PEI<). This tells you the base polymer. However, it often doesn't specify the exact grade (e.g., standard PEEK vs. glass-filled PEEK), which can affect temperature ratings. It's a good starting point, but not the full story.

3. Consider the Source and Application

Where did the plastic come from? If it was specified for a known high-temperature application (e.g., aerospace component, medical sterilization tray), it's likely heat-resistant. If you bought stock material, the supplier should provide documentation. If it's an unknown part, tracing its origin can give clues.

4. Physical Characteristics (Use with Caution!)

Some high-performance plastics have characteristic appearances:

- PEEK is often beige or tan (unfilled).

- Ultem (PEI) is typically amber and translucent.

- PTFE is almost always white and feels slippery, slightly waxy.

- PI (like Vespel) is often dark brown or black.

However, colors can vary with fillers and grades, so this is not a reliable identification method alone. Trying to test by heating is destructive and generally not recommended unless you have specific test equipment and know what you're doing.

Always prioritize official documentation (datasheets) for reliable information. When ordering material for CNC machining, specifically request the datasheet to confirm its properties meet your requirements.

What is the best plastic for CNC machine?

Looking for the single "best" plastic for CNC machining? It's tricky because different materials excel in different ways, and some are much harder to machine than others. Let's find the balance.

There isn't one "best" plastic; it depends on your project's needs (heat resistance, strength, chemical exposure) balanced with machinability. Materials like Acetal (POM), PEEK, Nylon (PA), and PEI (Ultem) often offer a good combination of desirable properties and reasonable machinability.

The ideal plastic for CNC machining is one that meets your application requirements and can be efficiently and accurately shaped by the machine without causing issues like melting, excessive tool wear, or poor surface finish. From my experience running a CNC shop, some materials are a dream to work with, while others require special care.

Balancing Properties and Machinability

When selecting a plastic for CNC, consider these factors:

- Application Requirements:

- Temperature: Does it need to be heat resistant? (As discussed previously)

- Mechanical Strength: Does it need to be strong, stiff, or impact resistant?

- Chemical Resistance: Will it be exposed to solvents, acids, or bases?

- Wear Resistance: Will it rub against other parts?

- Electrical Properties: Does it need to be an insulator or static dissipative?

- Cost: What's the budget?

- Machinability:

- Chip Formation: Does it produce clean chips or long, stringy ones? Does it create dust?

- Melting Point/Softening: Does it melt easily from tool friction, requiring careful speed/feed/cooling?

- Tool Wear: Is it abrasive, wearing out cutting tools quickly? (Filled grades are often worse).

- Achievable Tolerances/Finish: Can it hold tight dimensions and provide a smooth surface?

- Brittleness: Is it prone to chipping or cracking during machining?

Common CNC Plastics and Their Trade-offs

| Material | Heat Resistance | Strength | Machinability | Relative Cost | Typical Use Case |

|---|---|---|---|---|---|

| Acetal (POM) | Low | Good | Excellent | Low | General purpose gears, bushings, fixtures |

| Nylon (PA) | Low-Moderate | Good | Good | Low | Wear parts, rollers, structural components |

| UHMW-PE | Very Low | Moderate | Moderate | Low | Wear strips, low-friction surfaces |

| Polycarbonate (PC) | Moderate | Good (Tough) | Fair | Moderate | Guards, transparent parts |

| PEI (Ultem) | High | High | Moderate | High | High-temp structural, medical, electrical |

| PEEK | Very High | Very High | Moderate | Very High | Extreme temp/chemical, aerospace, medical |

| PTFE | Very High | Low | Easy (Gummy) | Moderate | Seals, insulators, low-friction, chemical |

| PI (Polyimide) | Highest | High | Difficult | Highest | Extreme temp seals, wear pads, semiconductors |

My Experience: For general-purpose parts where high heat isn't a factor, Acetal (POM) is fantastic – it machines beautifully. When heat resistance becomes important, we often move to PEI (Ultem) or PEEK. Ultem offers a good balance, while PEEK is for the really tough jobs. PTFE is easy to cut but needs sharp tools and careful handling to avoid deformation. Polyimides are reserved for applications where nothing else will survive the heat, and we accept the machining challenge and cost. Always adjust cutting speeds, feed rates, and use coolant appropriately for the specific plastic.

Which plastics do not melt on heating?

Concerned about plastics completely losing their form under heat? Some applications demand materials that simply won't melt. Let's clarify which plastics fit this description.

Thermosetting plastics, like Polyimides (some types), Phenolics, and Epoxies, do not melt upon heating. Instead, they undergo irreversible chemical changes (curing) and will char or decompose at very high temperatures. Most high-temp CNC plastics (PEEK, PTFE, Ultem) are thermoplastics; they do melt, but at very high temperatures.

The key difference lies in the fundamental structure of the plastic: whether it's a thermoplastic or a thermoset. Understanding this difference is crucial when selecting materials where melting is absolutely unacceptable.

Thermoplastics vs. Thermosets

Let's quickly compare these two main categories of polymers:

Thermoplastics

- Behavior on Heating: Soften when heated, eventually melt into a liquid state. They re-solidify when cooled.

- Structure: Long polymer chains with weak intermolecular forces holding them together. Heating allows these chains to slide past each other.

- Processing: Can typically be melted and reformed multiple times (e.g., injection molding, extrusion). This makes them generally easier to process and recycle (in theory).

- CNC Machining: Most common plastics for CNC machining fall into this category. Their ability to soften requires careful control of heat generated during cutting to prevent melting onto the tool or workpiece.

- High-Temp Examples: PEEK, PTFE, PEI (Ultem), PPS, Nylon, Polycarbonate. These have high melting points or glass transition temperatures but will melt or significantly soften if heated enough.

Thermosets

- Behavior on Heating: Once cured (set), they do not melt. Applying excessive heat will cause them to degrade, char, or burn, but they won't flow like a liquid.

- Structure: Polymer chains are chemically cross-linked during curing, forming a rigid, three-dimensional network. These strong covalent bonds prevent chains from moving when heated.

- Processing: Typically formed into shape before or during curing. Cannot be remelted or reshaped after curing.

- CNC Machining: Thermosets can be machined, but they often behave differently than thermoplastics. They tend to be harder and more brittle, producing dust or chips rather than continuous strings. Tool wear can be higher.

- High-Temp Examples: Polyimides (many forms, like Vespel®), Phenolics (Bakelite), Epoxies, Silicones, Melamine Formaldehyde.

So, if your absolute requirement is a material that will not melt under any heat (though it might degrade), you need a thermoset. Polyimide (PI) is often the most relevant high-temperature thermoset (or behaves like one) that is commonly machined for demanding applications. However, most high-performance machined parts use high-temperature thermoplastics like PEEK or PEI, relying on their very high melting points to operate safely within their specified continuous use temperatures.

Conclusion

Choosing the right heat-resistant plastic like PEEK, PTFE, PI, or Ultem is vital for CNC parts in hot environments. Consider temperature needs, machinability, and cost to ensure successful, reliable components.

Footnotes:

-

Explore this link to understand the various types of heat-resistant plastics and their specific applications in different industries. ↩

-

Explore this link to understand the diverse applications and advantages of PEEK, a material known for its exceptional properties in demanding environments. ↩

-

Explore this link to understand the unique properties and applications of PTFE, a versatile material widely used in various industries. ↩

-

Discover the advantages and challenges of PI, a top-tier material for heat resistance, crucial for high-performance applications. ↩

-

Understanding Continuous Service Temperature is crucial for selecting materials for long-term applications. Explore this link to learn more. ↩

-

Understanding HDT is crucial for selecting materials in high-temperature applications. Explore this link for in-depth insights. ↩

-

Learn how Tg influences the performance of amorphous plastics, essential for material selection in engineering. ↩

-

Discover the significance of Tm in material behavior and applications, vital for engineers and designers. ↩