Last Updated: 2025-10-21 09:17:51 Tuesday

Choosing between manual turning equipment and CNC lathe systems can be challenging, especially when expanding your manufacturing capabilities or upgrading existing shop floor equipment. Making the wrong investment decision can impact your bottom line through lost productivity, inconsistent part quality, and missed deadlines - challenges we've helped countless manufacturers overcome at Allied Metal.

For most production environments, CNC turning centers deliver superior performance through faster cycle times, consistent quality output, streamlined complex geometry production, and enhanced precision capabilities. Conventional manual lathes maintain relevance for specific applications including simple prototyping, maintenance repairs, and training scenarios.

Both machining approaches rotate raw material against cutting tools to shape components, but their control methodologies create significant divergence in operational efficiency and technical capabilities. Let's examine the critical distinctions and competitive advantages of each approach.

Is CNC Generally Considered Better Than Manual Machining?

When your manufacturing requirements demand rapid production with exacting repeatability, manual machining processes can introduce variability between operators and extended production timelines. These inconsistencies create operational friction and increased costs, particularly with larger batch sizes.

Yes, for the majority of industrial manufacturing scenarios involving production volumes, complex part geometries, or stringent tolerance requirements, computer-controlled machining is widely regarded as superior to manual operation due to automated processes, exceptional repeatability, and precision engineering capabilities.

Computer Numerical Control technology eliminates human variability from the cutting process entirely. Once programmed, CNC equipment can produce components with near-identical characteristics continuously, operating 24/7 production cycles when required. Traditional manual machining depends completely on operator skill and concentration for every individual cutting operation, naturally introducing minor variations and extending per-part production time. While experienced manual machinists remain invaluable assets, CNC automation systems1 typically deliver superior performance for production runs where manufacturing efficiency and quality consistency are paramount.

Real-World Manufacturing Case Study:

We recently supported an aerospace components manufacturer struggling with production bottlenecks on a contract for 1,200 precision hydraulic fittings. Their manual turning process required 38 minutes per component while maintaining ±0.075 mm tolerances. After implementing our CNC turning solutions with automated tool changing, cycle times reduced to 7 minutes per part while consistently achieving ±0.008 mm tolerances. This transformation decreased their direct labor costs by 68% while enabling them to expand their precision component manufacturing services into more demanding aerospace and defense applications.

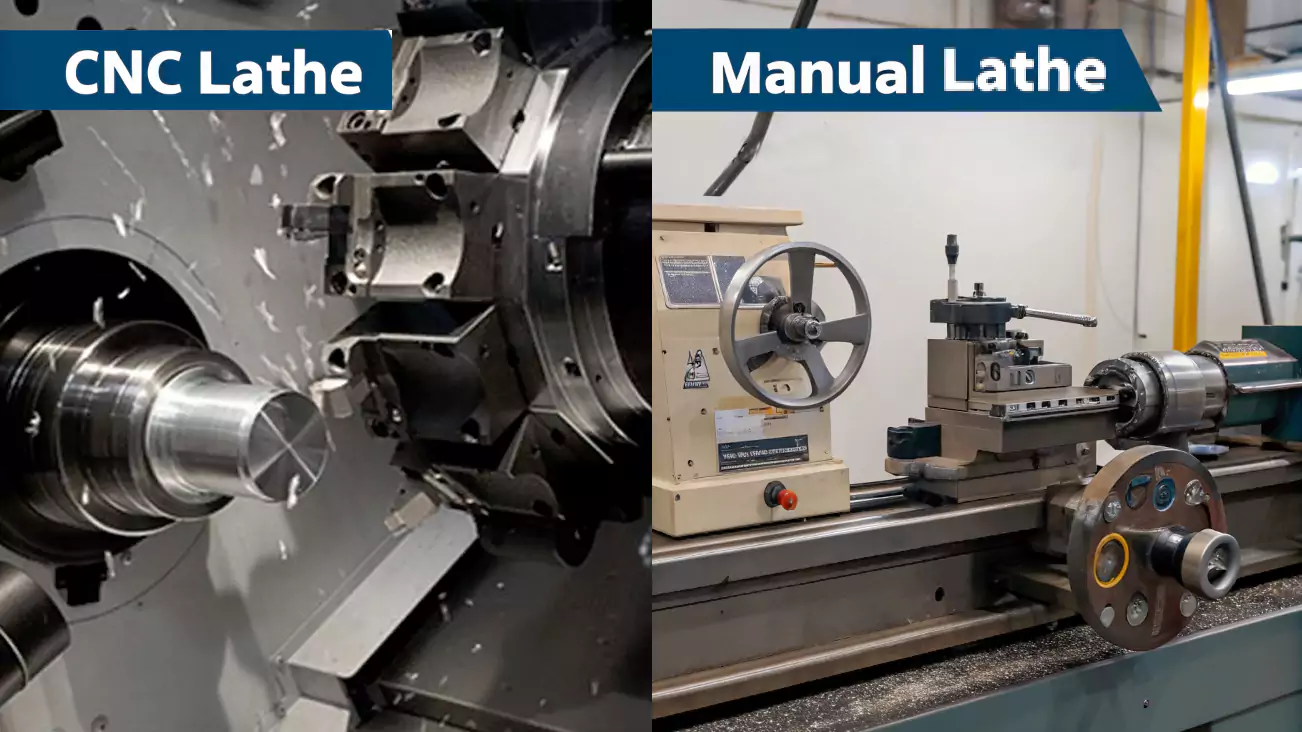

What is the Core Operational Difference Between CNC and Manual Turning Equipment?

Both technologies rotate workpieces and engage cutting tools, so what fundamentally distinguishes their operation? Misunderstanding these core differences can lead to capital equipment investments misaligned with your production requirements.

The essential distinction resides in control systems: CNC turning equipment utilizes programmed computer instructions (G-code) to autonomously manage tool trajectories, spindle speeds, and operational sequences, while manual lathes require continuous operator intervention through handwheel manipulation and lever control.

Imagine producing a perfect spherical profile. A manual lathe operator employs accumulated skill and coordinated hand movements, manually adjusting control wheels with precision developed through experience. A CNC turning center interprets digital instructions defining that geometry and executes them with exacting repeatability. The CNC program governs tool paths, rotational speeds, feed rates, coolant application, and automatic tool changing sequences. The technician prepares the machine, loads the program, monitors operations, and makes parameter adjustments, but doesn't manually execute each cutting operation. On conventional equipment, the operator functions as the integrated control system, continuously making adjustments based on tactile feedback, auditory cues, and dimensional verification. This hands-on control methodology provides advantages for rapid, simple components or modifications, but presents significant challenges for complex contours or high-volume repeatability compared to computer-directed systems.

Why Do Manufacturing Facilities Prefer CNC Turning Centers Over Conventional Manual Lathes?

Conventional manual lathes present lower initial capital investment, so why do progressive manufacturing operations allocate significant resources to CNC technology? Exclusive reliance on manual equipment can constrain competitive positioning regarding production velocity, geometric complexity, and precision capabilities.

CNC lathes receive preference for their enhanced production throughput, superior dimensional accuracy and repeatability, streamlined production of sophisticated geometries, and reduced operator intervention with lower per-part labor costs in volume production environments.

The manufacturing preference stems from substantial competitive advantages in production settings:

- Throughput: CNC systems operate at optimized cutting parameters with minimal non-cutting time between operations through automated sequencing.

- Precision & Repeatability: Once programmed, CNC equipment maintains target specifications consistently across production batches, typically maintaining tighter tolerances than manually achievable over extended runs.

- Geometric Complexity: Generating tapers, radii, threaded features, and complex contours is programming-dependent rather than skill-dependent with CNC systems.

- Labor Efficiency: While skilled technicians remain essential for setup, a single operator can frequently supervise multiple CNC machines, dramatically reducing direct labor allocation per finished component.

- Automation Integration: CNC turning centers readily integrate with bar feeding systems, robotic part handling, and pallet changers for extended unmanned operation - capabilities unavailable with manual equipment.

These operational advantages establish CNC turning technology as the foundation of contemporary manufacturing for rotational components, particularly in custom machined parts production and precision component manufacturing services.

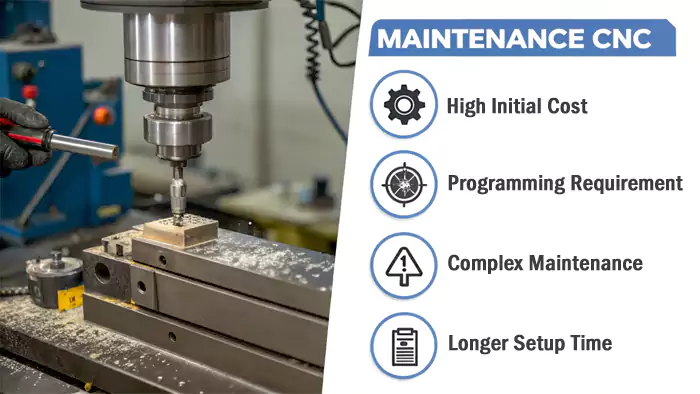

What Operational Challenges Do CNC Lathes Present?

CNC technology appears ideal, but what limitations exist? Overlooking these considerations can result in unanticipated expenses and operational constraints, particularly for smaller enterprises or specialized applications.

Primary limitations of CNC turning systems include substantial initial capital expenditure, requirement for programming expertise (and supporting software), increased maintenance complexity from sophisticated electronics, and potentially extended setup durations for straightforward, single-component production.

Despite their capabilities, CNC turning centers present specific operational challenges:

- Capital Investment: CNC lathes command significantly higher purchase prices than conventional manual equipment. Advanced control systems, drive mechanisms, and precision components contribute to elevated costs.

- Programming Requirements: Technical personnel capable of machine programming using G-code or CAM software platforms2 are essential. This demands specialized knowledge and ongoing training investment.

- Maintenance Complexity: CNC systems incorporate sophisticated electronic components (control boards, positioning sensors, drive systems) requiring specialized diagnostic capabilities and repair expertise, potentially extending downtime during technical issues.

- Setup Duration: For elementary, single-component production (such as facing a bar stock end), an experienced manual machinist might complete the task more rapidly than CNC programming, loading, and verification processes require.

- Process Modification3: Implementing immediate adjustments during cutting operations is more straightforward on manual equipment. CNC systems typically require program modifications.

These factors confirm that conventional manual lathes retain important roles in technical training, maintenance departments, straightforward prototyping, and toolroom environments where operational flexibility and minimal capital outlay outweigh production speed considerations.

Conclusion

CNC turning centers deliver significant advantages in production speed, dimensional precision, quality consistency, and complex component manufacturing, establishing them as the preferred solution for most production scenarios. Conventional manual lathes maintain utility for simple prototypes, repair work, and skills development. For manufacturing businesses focused on precision component manufacturing and scalable custom machined parts production, strategic investment in CNC technology delivers measurable returns in operational efficiency and quality assurance.

Footnotes:

-

Discover how CNC automation systems can revolutionize manufacturing efficiency and quality management in your operations through this comprehensive technical resource. ↩

-

Implementing CAM software solutions enhances CNC machining process optimization and manufacturing productivity through advanced programming capabilities. ↩

-

Exploring Process Modification will provide insights into the flexibility and adaptability of CNC operations. ↩