Designing moving parts but facing issues with wear, friction, or misalignment? These problems can lead to premature failure, costly repairs, and unreliable system performance.

A bushing is a cylindrical mechanical component that acts as a liner for a rotating or sliding shaft. It provides a bearing surface to reduce friction and wear between moving parts.

In my years of CNC machining at Allied Metal, I’ve manufactured thousands of components, but some of the most critical are also the simplest in appearance: bushings. To me, a bushing is more than just a spacer — it’s a precision component that absorbs stress, ensures alignment, and protects other parts from wear. For engineers like David, who design complex automation systems, selecting or designing the right custom bushing is fundamental. The quality of a machined bushing can directly impact the accuracy of a machine's movement and the longevity of the entire assembly. It’s one of those small parts that makes a huge difference.

What Exactly Is a Bushing in the World of Machining?

The term "bushing" is common in mechanical design. But what defines this component, and what is its fundamental role from a machinist's perspective?

In machining, a bushing is a type of plain bearing, typically a hollow cylinder, that lines a hole to provide a low-friction surface for a shaft, pin, or hinge.

Diving Deeper into the Definition of a Bushing

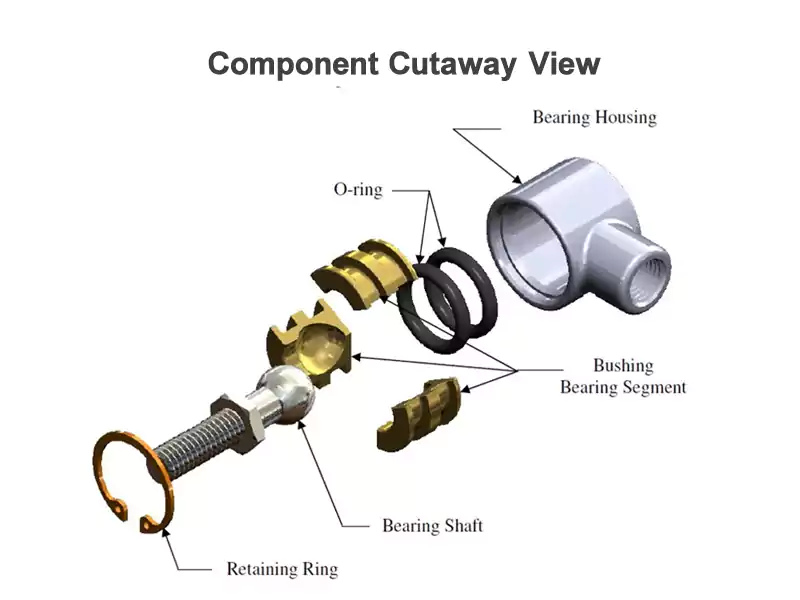

In the world of mechanical engineering and machining, a bushing is an essential component that serves as a removable sleeve or liner. Its primary function is to create a low-friction interface between two moving parts, most commonly a rotating or sliding shaft and its housing. It is, in fact, the most common type of plain bearing.

Unlike complex ball bearings or roller bearings, which use rolling elements to reduce friction, a sleeve bushing1 relies on the properties of its material and often a lubricant to allow for smooth, sliding motion. The basic design is a simple cylinder, but this simplicity hides its critical importance.

From a manufacturing standpoint at Allied Metal, we see a precision bushing as a sacrificial component designed to wear out over time. This is a deliberate and smart design choice. It is far easier and cheaper to replace a worn bronze bushing2, for example, than it is to replace a large, expensive shaft or to repair a damaged housing bore. The bushing takes the brunt of the wear and tear, protecting the more valuable components of the assembly. Whether it's a simple sleeve bushing or a more complex flange bushing with a lip for axial location, its job is to provide a reliable, low-friction, and replaceable bearing surface.

What Is the Main Purpose of Using a Bushing in a Mechanical Assembly?

Why not just let a metal shaft rotate in a metal hole? What specific problems does a bushing solve, and what functions does it perform?

The purpose of a bushing is to reduce friction and wear, provide support and alignment for moving parts, absorb shock and vibration, and act as a sacrificial component.

Diving Deeper into the Functions of a Bushing

A bushing is a multi-function component that solves several key challenges in mechanical design. Its purposes go far beyond simply filling a gap. For an engineer, incorporating the right custom bushing is a strategic decision to improve a machine's durability and performance.

Reducing Friction and Wear

This is the most fundamental purpose. When a metal shaft rotates directly inside a metal housing, it can lead to high friction, heat generation, and galling (a form of wear caused by adhesion between sliding surfaces). A bushing made from a material with a low coefficient of friction, like bronze or a specialized polymer, provides a smooth surface for the shaft to turn against. This drastically reduces friction and prevents wear on the more critical and expensive components.

Ensuring Precise Alignment and Support

A precision bushing provides tight, controlled clearance around a shaft. This ensures the shaft is accurately located and supported, preventing unwanted radial movement or "slop." Proper alignment is critical for the function of gears, pulleys, and linkages, ensuring they operate smoothly and transfer power efficiently.

Absorbing Stress and Vibration

Bushings can also act as dampers. Materials like rubber, certain polymers, or even softer metals like bronze have inherent vibration-damping properties. In applications like vehicle suspension systems, suspension bushings3 absorb shocks from the road, isolating the chassis from harsh vibrations and providing a smoother ride.

Acting as a Sacrificial Component

As I mentioned, this is a key economic purpose. The bushing is designed to be the part that wears out first. Replacing a worn machined bushing is a quick and inexpensive maintenance task. Without it, the shaft and its housing would wear directly on each other, leading to a much more costly and difficult repair. It's a classic example of smart, sacrificial design.

Where Are Bushings Commonly Used in Real-World Applications?

Knowing the purpose is one thing, but where would you actually find these components? What are some common examples of bushings in action across different industries?

Bushings are used everywhere, from automotive suspension systems and industrial machinery pivots to aerospace control surfaces and even simple door hinges. They are fundamental to most moving mechanical parts.

Diving Deeper into Bushing Applications

Bushings are ubiquitous in mechanical engineering. Once you know what to look for, you'll see them in countless applications across every industry. Their versatility makes them a go-to solution for managing friction and wear in moving assemblies. For David, many of these applications will be familiar from his work in industrial automation.

Here are some common real-world examples:

-

Industrial Automation & Robotics: In the pivot points of robotic arms, a

precision bushingensures smooth and accurate movement. They are also used extensively in conveyor belt rollers, linear guide systems, and the linkages of automated machinery. -

Automotive: This is a huge area for bushings. You'll find them in:

- Suspension Systems: Control arm bushings, sway bar bushings, and shock absorber mounts are critical for ride quality and handling.

- Engine Components: Piston pin bushings (wrist pin bushings), starter motor bushings, and sometimes camshaft bushings.

- Other Areas: Clutch and brake pedal pivots, steering rack mounts, and windshield wiper mechanisms.

-

Aerospace: In aerospace, reliability is paramount. Bushings are used in landing gear pivot points, flight control surface hinges (for ailerons, elevators, and rudders), and cargo door mechanisms.

-

Manufacturing & Tooling: A specific type of hardened steel bushing, known as a drill bushing4, is a key component in jig design. As we've discussed before, it precisely guides a drill bit to ensure accurate hole placement.

-

Construction and Agricultural Equipment: The heavy-duty pivot points on excavators, bulldozers, and tractors rely on robust, hardened steel bushings to withstand immense loads and harsh environments.

-

Consumer Products: From the simple hinge on an oven door to the pivots in exercise equipment and the pedals on a bicycle, bushings are used to provide smooth, quiet, and durable motion.

The widespread use of the bushing demonstrates its fundamental importance in mechanical design.

How Is a Precision Bushing Manufactured Using CNC Machining?

A bushing can seem like a simple cylinder. What manufacturing processes, especially CNC machining, are used to create a high-quality precision bushing with tight tolerances?

A machined bushing is typically produced using CNC turning to create the core cylindrical shape and precise diameters, followed by milling for features like oil grooves or mounting holes.

Diving Deeper into the Bushing Manufacturing Process

Creating a high-quality precision bushing that meets the tight tolerances required by engineers involves several key manufacturing steps, with CNC machining at the core. While the final shape may look simple, the process to achieve its accuracy is meticulous.

1. Material Selection

The first step is choosing the right bushing material. This choice depends on the application's requirements for load, speed, friction, temperature, and corrosion resistance.

- Bronze Alloys (e.g., Oil-impregnated, Aluminum Bronze): Very common due to their excellent lubricity, wear resistance, and good machinability.

- Steel and Stainless Steel: Used for high-load, high-strength applications. Often hardened and ground for extreme durability.

- Engineering Plastics (e.g., Nylon, Delrin®, PEEK, Teflon™): Ideal for low-friction, corrosion-resistant, and lightweight applications. Some are self-lubricating.

- Brass: Good corrosion resistance and easy to machine, used in plumbing and electrical applications.

2. CNC Turning

For any sleeve bushing or flange bushing, the primary manufacturing process is CNC turning.

- A piece of bar stock of the chosen material is loaded into a CNC lathe.

- The lathe performs several operations with high precision:

- Facing: Creates a flat, smooth end on the part.

- Drilling/Boring: Creates the inside diameter (ID) to a precise size.

- Turning: Machines the outside diameter (OD) to its final dimension.

- Parting Off: Cuts the finished bushing to the correct length from the bar stock.

- If it's a

flange bushing, the lathe will also form the flange feature.

3. CNC Milling (for Secondary Features)

If the bushing requires features that aren't rotational, it will move to a CNC milling machine.

- Oil Grooves: Helical or straight grooves can be milled into the ID or OD to help distribute lubricant.

- Mounting Holes: Holes can be drilled and tapped into the flange of a

flange bushing. - Keyways or Flats: Milled features can be added to prevent the bushing from rotating in its housing or to lock a component to it.

4. Finishing Operations

For the highest precision, further steps may be required:

- Grinding or Honing: These processes can be used to achieve extremely tight tolerances on the ID or OD and produce a very smooth surface finish, which is critical for high-performance bearing applications.

- Deburring: All sharp edges are removed to ensure a smooth, safe part.

This combination of processes allows us at Allied Metal to produce any type of custom bushing to exact specifications.

Bushing vs. Bearing: What's the Real Difference?

The terms "bushing" and "bearing" are often used interchangeably, causing confusion. What is the fundamental distinction between a bushing and a bearing?

A bushing is a type of bearing, specifically a plain bearing with no moving parts. The term "bearing" often refers to rolling-element bearings (like ball bearings), which use balls or rollers.

Diving Deeper into the Bearing Family

This is a very common point of confusion, even among technical professionals. Let's clarify it for David and others. The key is understanding that a bushing is a type of bearing. The confusion arises because people often use the generic term "bearing" when they are specifically talking about a rolling-element bearing.

The two main families of bearings are:

- Plain Bearings (Bushings): These are the simplest type. They consist of a single, solid piece of material that provides a bearing surface for sliding contact. There are no moving parts within the bearing itself.

- Rolling-Element Bearings: These use spheres (ball bearings) or cylinders (roller bearings, needle bearings) to separate the moving surfaces. The motion is primarily rolling, not sliding.

Here's a breakdown comparing the two, which addresses the common "bushing vs. bearing" question:

| Feature | Plain Bearing (Bushing) | Rolling-Element Bearing (e.g., Ball Bearing) |

|---|---|---|

| Principle of Operation | Sliding Contact (surfaces slide against each other) | Rolling Contact (balls or rollers roll between surfaces) |

| Friction Type | Sliding Friction (generally higher, especially at start-up) | Rolling Friction (generally lower, especially at higher speeds) |

| Construction | Simple, one-piece (e.g., a solid cylinder or sleeve). | Complex, multi-component (inner race, outer race, balls/rollers, cage). |

| Speed Capability | Best for lower speeds, oscillating, or intermittent motion. | Better for continuous high-speed rotation. |

| Load Capability | Excellent load-carrying capacity due to large contact area. | Load capacity depends on the size and number of rolling elements. |

| Shock Resistance | Very good. The solid construction handles shock and impact loads well. | Less tolerant of shock loads, which can damage the races or rolling elements. |

| Noise Level | Very quiet in operation. | Can generate some noise due to the rolling elements. |

| Cost | Generally much less expensive. | More expensive due to complexity. |

| Contamination Tolerance | Can often be designed to tolerate contaminants better. | Highly sensitive to contamination, which can cause premature failure. |

When to Choose Which:

- Choose a

bushingfor high-load, low-speed applications, oscillating movements, situations requiring shock resistance, or when cost and simplicity are major drivers. - Choose a rolling-element

bearingfor high-speed, continuous rotation applications where minimizing friction is the absolute top priority.

Conclusion

A bushing is a critical component that reduces friction, prevents wear, and ensures alignment. Choosing the right material and design is key to mechanical longevity and performance.

-

Explore this link to understand the various applications and benefits of sleeve bushings in mechanical systems. ↩

-

Discover the benefits of bronze bushings, including durability and wear resistance, crucial for machinery performance. ↩

-

Learn how suspension bushings contribute to a smoother ride and better vehicle handling. ↩

-

Discover the importance of drill bushings in achieving precision in manufacturing processes and jig design. ↩