The wrong cover can weaken a motorcycle’s structure, overheat key areas, or fail during vibration. Many buyers discover this only after parts crack or warp.

A custom motorcycle cover is a shaped protective shell or fairing made to match a specific model’s dimensions, mounting points, airflow requirements, and durability needs. It improves protection, stiffness, heat control, and style while fitting the motorcycle with engineering-level precision.

When I began producing custom covers for motorcycle manufacturers twenty years ago, I learned that most failures came from poor design, weak materials, or cheap forming methods. This article explains how to choose the right material, process, and supplier so you can avoid expensive trial-and-error and get covers that work in real-world riding conditions.

What is a Motorcycle Cover?

Motorcycle covers protect the motorcycle body, shape airflow, and give the bike a clean, controlled exterior form. When a cover fits poorly, stress cracks, vibration noise, and heat buildup can appear fast.

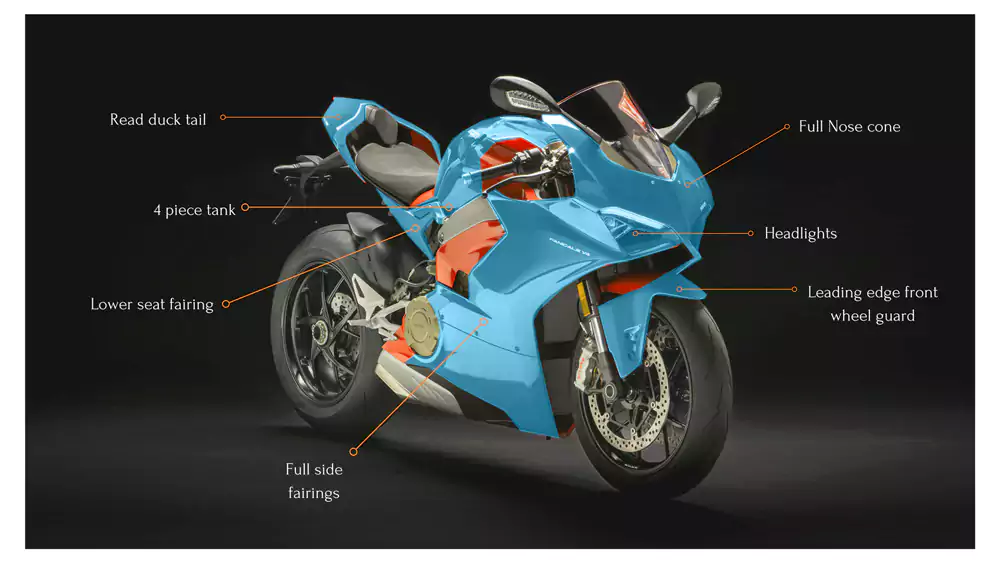

A motorcycle cover is an exterior panel or fairing designed to shield structural parts, direct airflow, and create a stable mounting surface. It must match the exact geometry and attachment points of the motorcycle.

A cover can be a side panel, tail cover, tank shell, or full fairing1. Each one has a unique role. A full fairing guides wind to reduce drag. A side cover hides electronics and wiring. A tank shell gives shape and protects the fuel tank. Many manufacturers choose custom covers when they want special branding or need improvements in durability. Even small geometry changes can affect rider comfort and aerodynamic behavior. Because of this, custom covers must be engineered like structural components, not decorations.

What is the Purpose of a Custom Motorcycle Cover?

Many buyers come to me only after an OEM part cracks or vibrates at high RPM. Their first question is always the same: why did the original cover fail?

The purpose of a custom motorcycle cover is to give better protection, better heat flow, stronger mounting points, and a precise fit. It improves durability, airflow, noise control, and styling in ways generic covers cannot.

Custom covers allow design teams to improve aerodynamics2, hide electronics, manage airflow toward hot zones, or strengthen areas that run under constant vibration. They also support brand styling, which matters a lot in the European market. A smart design reduces riding noise, protects sensors, and keeps cables stable.

What is the Best Material for Motorcycle Covers?

I learned early in my career that choosing the wrong material destroys an otherwise perfect design. Some customers want aluminum for strength but ignore weight. Others want ABS for cost but forget about UV resistance.

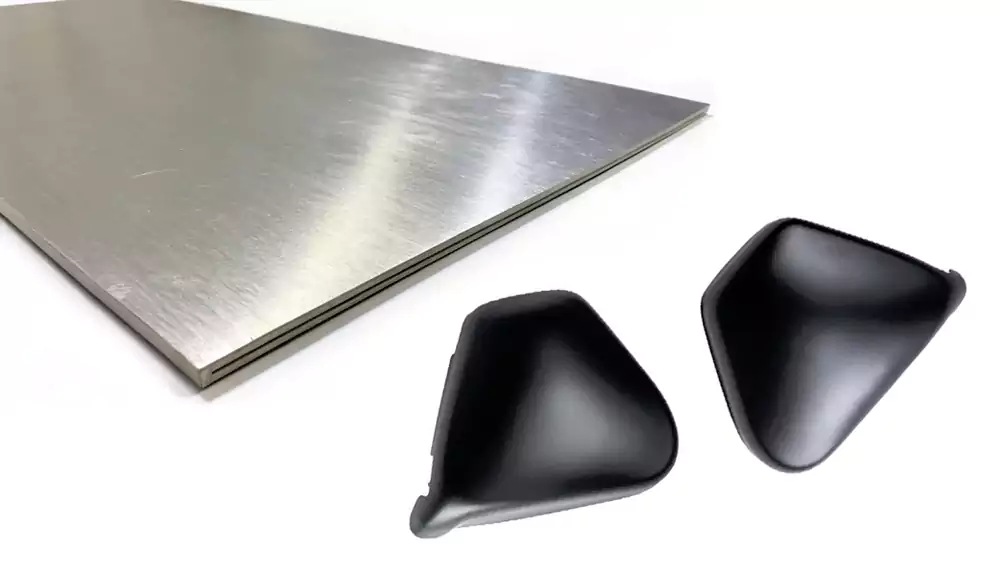

The best material depends on weight needs, heat exposure, impact strength, riding conditions, and the production quantity. Aluminum, ABS, fiberglass, and carbon fiber each work well for different goals.

I often explain material choices using simple decision factors. Below is a breakdown you can use:

Material Comparison Table

| Material | Strength | Weight | Heat Resistance | Cost | Best Use |

|---|---|---|---|---|---|

| Aluminum (CNC) | Very high | Medium | Excellent | Medium-high | Structural covers, small batches |

| ABS | Medium | Low | Good | Low | Mass production |

| Fiberglass | Medium-high | Medium | Good | Medium | Custom styling, mid batch |

| Carbon Fiber | Very high | Very low | Excellent | High | Performance motorcycles |

Aluminum offers the best precision. I like it for covers near engines because it pulls heat away fast. ABS gives the lowest cost. Fiberglass works well for complex shapes. Carbon fiber gives the best strength-to-weight balance. A smart buyer matches the material to the real riding environment, not the catalog.

Common Manufacturing Methods for Motorcycle Covers?

Many people believe motorcycle covers are simple shells. They are not. The making process decides the strength, the finish, and even the mounting reliability.

Common manufacturing methods include CNC machining, vacuum forming, injection molding, and fiberglass layup. Each method suits a different quantity and strength requirement.

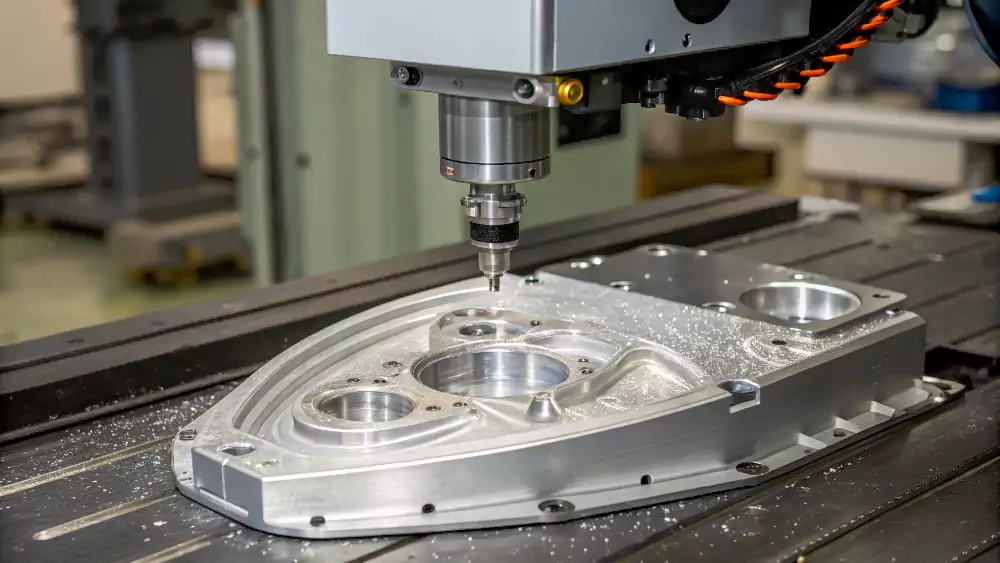

CNC Machining

CNC machining gives the best precision. I use it for prototypes or small batches. Tolerances can reach ±0.05 mm. Milling aluminum or composite blocks gives excellent strength and accurate mounting holes.

Vacuum Forming

Vacuum forming3 works for ABS and offers fast cycle time. It gives good shape but medium precision. It is the usual choice for medium-volume runs.

Injection Molding

Injection molding4 is ideal for large production runs. The tooling cost is high, but the per-part price is low. The repeatability is great.

Fiberglass Layup

Fiberglass is good for custom aerodynamic covers. Weight is moderate and cost is flexible. It needs manual work and offers medium precision.

Key Engineering Considerations in Motorcycle Cover Design and Production?

In my early years, most customer revisions came from small mistakes: weak mounting tabs, uneven wall thickness, or blocked airflow passages. These are avoidable.

The key engineering considerations include wall thickness, airflow paths, mounting geometry, tolerance control, vibration resistance, and the planned surface finish.

Structural Fit

Covers must match the frame, not just the CAD model. Real motorcycles often have ±1–2 mm assembly variations. I adjust mounting slots to avoid stress.

Heat Management

Aluminum and composite covers behave differently near engines. Aluminum pulls heat away. Carbon fiber shields heat. A good design uses both if needed.

Vibration Control

Motorcycles vibrate. I like to reinforce screw bosses or add ribs to prevent cracks.

Surface Treatment

Anodizing, powder coating, and clear-coat carbon fiber give strong protection. Anodizing forms a hardened layer that stays bonded to the metal.

Motorcycle Cover Case Studies?

Years ago, a European motorcycle brand asked me to fix a problem: their aftermarket side covers warped near the exhaust pipe.

A CNC-machined 6061-T6 aluminum cover with a 3.0 mm wall thickness solved the heat issue and doubled service life.

Case Study Table — 6061-T6 Aluminum Side Cover

| Parameter | Value |

|---|---|

| Material | 6061-T6 Aluminum |

| Manufacturing Method | CNC Milling, 3-axis |

| Wall Thickness | 3.0 mm |

| Tolerance | ±0.05 mm |

| Surface Treatment | Black Anodized, Hardness ~HV 400 |

| Operating Temp | 120°C Peak |

| Mounting Points | 4 reinforced bosses |

| Weight | 268 g |

| Batch Size | 30 pcs |

The original ABS cover could not handle exhaust heat. By switching to aluminum and using rib reinforcement, we reduced deformation to almost zero. Anodizing also protected the surface while giving a clean matte finish that matched the brand style.

How to Obtain a Custom Motorcycle Cover?

Many engineers ask me how to start. The answer is simple: give complete details early. Missing dimensions cause delays.

You can obtain a custom cover by sending CAD data, photos, or samples to a machining partner who provides DFM feedback, makes a prototype, and then produces the final batch.

Here is the workflow most engineers and buyers use:

1. Share Your Design Inputs

You can start with:

- CAD files (STEP / IGES / STL)

- 2D drawings

- Hand sketches with basic measurements

- Or an old cover for reverse engineering

This provides the geometry and mounting layout needed to begin.

2. Engineering Check

We review the part with real riding conditions in mind:

- Mounting positions and hole spacing

- Thickness and rib strength

- Heat-exposed zones near the engine

- Required tolerances

- Material selection (aluminum, ABS, fiberglass, carbon fiber)

You receive simple, direct DFM feedback so you can adjust the design quickly.

3. Prototype Production

A prototype is then produced to confirm:

- Actual motorcycle fit

- Vibration and thermal behavior

- Mounting strength

- Surface finish quality

- Any small geometry adjustments

This step prevents issues before entering batch production.

4. Final Manufacturing

After approval, the final run is produced with:

- Stable and repeatable tolerances

- Consistent surface quality

- Labeling and packaging (if needed)

- Predictable lead times

Why Many Engineers Work With Allied Metal

If you want a partner who keeps the process simple and engineering-focused, Allied Metal can help. 💬 Discuss with experts

We provide:

- CNC machining for aluminum and composite covers

- Fast and clear DFM feedback

- Smooth communication

- Reliable quality across batches

- Experience producing hundreds of motorcycle components

If you have a new design—or want to upgrade an old one—you can contact us anytime. We are ready to help turn your idea into a finished cover that fits the motorcycle exactly the way you expect.

Conclusion

A custom motorcycle cover works best when the design, material, and process match the real riding demands. When these elements match, durability, fitment, and performance become predictable and dependable.

-

Learn about the aerodynamic advantages of full fairings and how they reduce drag for better performance. ↩

-

Learn about the crucial role of aerodynamics in improving vehicle efficiency and stability. ↩

-

Explore this link to understand how Vacuum forming can enhance production efficiency and product quality. ↩

-

Discover the benefits of Injection molding for high-volume manufacturing and cost-effectiveness. ↩