Editor’s Note: Last updated on October 30, 2025 by Lucy

Overview

CNC machining uses computer-controlled systems to operate machine tools, delivering complex parts with precision and efficiency. In my 20+ years on the shop floor, I’ve seen it revolutionize how we make everything from car engines to medical implants.

The Current State of CNC Machining

1. what is CNC Machining?

It’s about turning digital designs into physical parts with computer-controlled precision. Think of it as a robotic craftsman that never gets tired and always follows instructions to the letter.

2. Why CNC Machining?

- High accuracy: capable of micron-level machining accuracy.

- Consistency: Ensure consistency and repeatability of each part.

- Flexibility: Adapts to a wide range of materials and complex design requirements.

- Efficiency: reduces manual intervention and increases productivity.

Current Status of CNC Machining

1. Global Market Demand

With the globalization of manufacturing, the market demand for CNC machining continues to grow. According to market research, the global CNC machining market is expected to reach tens of billions of dollars by 2025, with a CAGR of between 5% and 7%.

2. Penetration rate

Since its introduction in 1950, the popularity of CNC machine tools has been increasing. According to statistics, the global penetration rate of CNC machine tools has reached 70%-80%.

In recent years, China’s CNC machine tool processing service system has become increasingly mature, and the level of engineering technology has been rapidly developed, not only to achieve localization, but also to improve the technology, such as 5-axis machining centers, high-speed milling machines, high-precision CNC lathes and so on.

3. Impact on Industries

The application of CNC machining technology has greatly promoted the development of automotive, aerospace, medical, electronics and other industries. It improves production efficiency, reduces manufacturing costs, and promotes the rapid launch of new products.

CNC Machining Market Demand and Industry Chain Analysis

Global Market Demand

The CNC market is booming, expected to hit $100+ billion by 2025. What I’m seeing daily confirms this – our order book has grown 30% year-over-year.

Technology Penetration

CNC machines now dominate modern workshops. About 80% of precision parts start with CNC programming. China’s particularly impressed me with their rapid adoption of 5-axis systems and high-speed machining centers.

Industry Impact

From automotive to medical, CNC enables the complex parts that modern products demand. Just last week, we machined surgical instruments, drone components, and custom motorcycle parts – all on the same equipment.

Why Choose Professional CNC Companies?

Here’s the reality from the trenches:

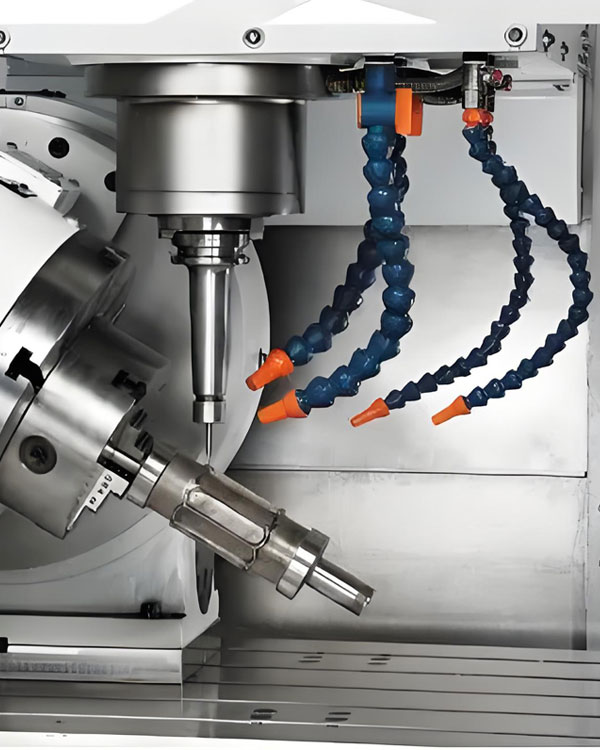

- Technical Capability: We run 5-axis machines that can produce geometries impossible with manual methods

- Experience: I’ve solved thousands of machining challenges – from chatter issues to material warping

- Cost Control: No capital investment in $200,000 machines for our clients

- Flexibility: Scale from prototype to production without missing a beat

Advantages of CNC machining in China

📌Case Study: Aerospace Heat Exchanger Plate

The Challenge: A German aerospace company needed 500 complex heat exchanger plates with micro-channels for satellite thermal management. Their local supplier quoted 12 weeks and couldn’t guarantee the 0.025mm wall thickness.

Our Solution: We took on the job using our Swiss-made 5-axis CNC mills with high-pressure coolant through the spindle.

Key Parameters & Results:

- Material: Aluminum 6061-T6

- Wall thickness: Achieved 0.024-0.026mm consistently

- Surface finish: Ra 0.8 μm without secondary operations

- Lead time: 6 weeks from order to shipping

- Cost: 40% below European quotes

- Quality: Zero rejects on first article inspection

The secret? Our team’s experience with thin-wall machining and China’s competitive tooling costs. We used custom carbide end mills and optimized cutting parameters to prevent part deflection.

Cost Advantage

Chinese manufacturing isn’t just about labor costs anymore. It’s about entire ecosystems – tooling suppliers, material distributors, and skilled programmers all working together efficiently.

Technology Breakthroughs

The gap has closed. We’re running the same German and Japanese machines you’d find anywhere in the world, with operators who’ve mastered them through years of hands-on experience.

Market Scale & Industrial Chain

When I need a special cutting tool or material, I’ve got suppliers who can deliver same-day. That supply chain efficiency translates directly to faster turnaround times for our clients.

Future Development Trends

The future development trend of CNC machining will be mainly reflected in the following aspects:

As the requirements for product quality increase, high-precision and ultra-precision machining technologies will become more and more important.

These technologies can achieve higher machining accuracy and smaller tolerances, especially in fields such as aerospace and medical devices, to meet the strict part accuracy requirements.

Intellectualization and automation will significantly improve the efficiency of CNC machining.

With the help of artificial intelligence and big data analysis, the equipment will be able to carry out production scheduling and fault diagnosis autonomously, thus optimizing the machining process and reducing labor costs. At the same time, automated production lines will enhance production flexibility and responsiveness.

The use of composite processing technology and multifunctional machine tools will further enhance processing efficiency.

These devices can complete multiple processing procedures on a single machine, reducing process changeover time, shortening production cycles, and better meeting the demands of small-lot, multi-variety production.

With the increasingly stringent environmental regulations, green processing and energy saving and emission reduction will become the focus of industry development.

By optimizing machining processes, using environmentally friendly materials and energy-saving equipment, the CNC machining industry will develop in a more sustainable direction, reducing resource consumption and environmental impact.

In summary, the future of CNC machining will develop in the direction of high-precision, intelligent, composite machining and green environmental protection to meet the growing market demand and environmental requirements.

Ⅶ. Summary

CNC machining continues to be the backbone of precision manufacturing. The shift toward smarter, more efficient, and more capable machining is accelerating. China’s role has evolved from low-cost alternative to technology leader in many segments.

At Allied Metal, we’ve stayed ahead by investing in both technology and people. Our team combines decades of hands-on experience with the latest equipment to deliver parts that meet global standards.