Editor’s Note: Last modified on November 7, 2025, by Lucy

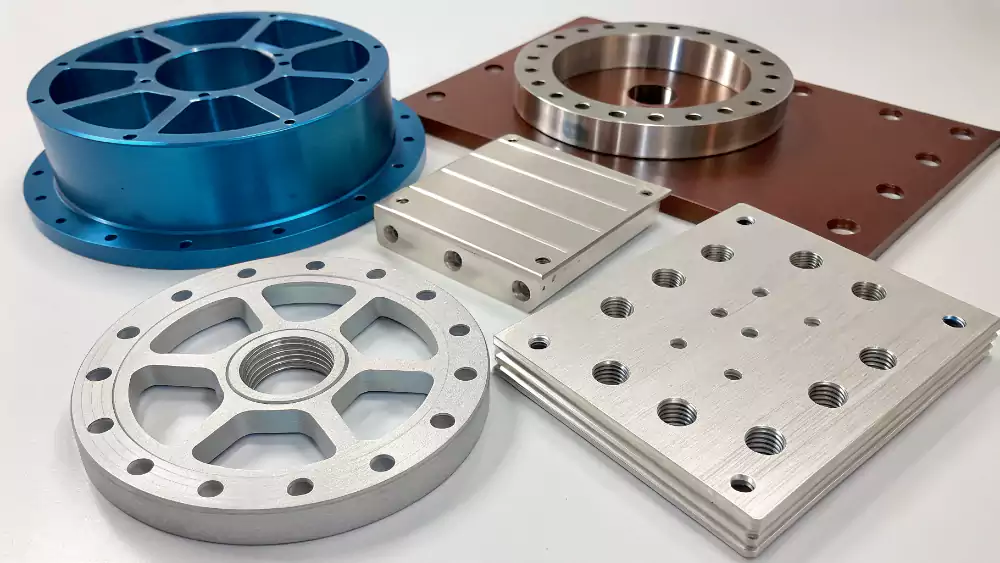

You’re looking for a spare part or a custom component. Chances are, you’re already leaning toward aluminum. Why? Because it’s the king of versatility. It’s light, machines like butter, and it’s strong enough for most jobs.

Machining spare parts from aluminum is the manufacturing industry’s go-to solution for lightweight, high-precision, and quick-turn components across aerospace, automotive, and electronics. The key is matching the right aluminum grade (6061, 7075, or 5052) with the correct surface finish (Anodizing, Chem Film, or Powder Coating) to meet the part’s final functional requirements.

I’ve been running parts on my mills for over 20 years, and I’ve probably cut more tons of aluminum than any other metal combined. For a procurement manager or engineer, aluminum is your friend—but only if you know the traps. Choosing the wrong alloy or surface treatment can ruin a perfect part. This guide is my non-negotiable checklist for sourcing aluminum spare parts like an expert.

Why is aluminum the Boss for Spare Parts?

Among all the metals used in CNC machining, aluminum stands out for its versatility and machinability. It’s lightweight, corrosion-resistant, and has excellent thermal and electrical conductivity — a combination that makes it suitable for a wide range of industries, from electronics to aerospace.

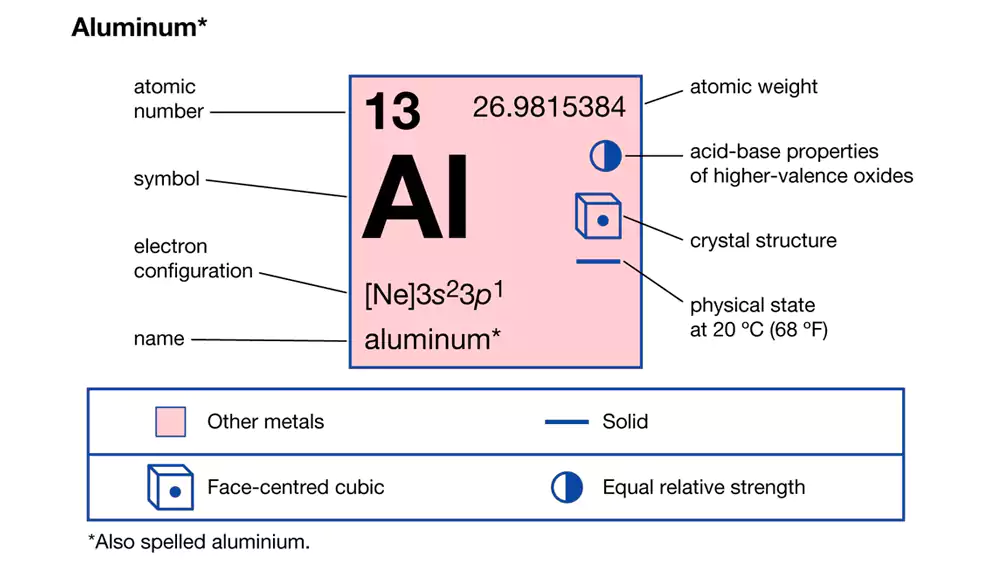

Key Characteristics of Aluminum

Aluminum is known for its lightweight nature — its density is only 2.68 g/cm³, roughly one-third that of steel.

It’s soft, ductile, and easy to shape, yet still durable. The melting point is around 640°C, which makes it easier to machine while maintaining sufficient structural strength.

Other useful properties include:

- Non-magnetic and non-flammable, suitable for sensitive applications.

- Excellent electrical conductivity, often used in power and electronic components.

- Naturally resistant to oxidation — and anodizing can further extend its corrosion protection.

Because of these advantages, aluminum CNC machining is widely used for mechanical housings, optical fixtures, heat sinks, jigs, molds, and electronic enclosures.

Why Aluminum Beats Other Metals?

Aluminum is preferred because:

- It’s easy to machine with tight tolerances.

- It dissipates heat efficiently during cutting, improving tool life.

- It provides an outstanding strength-to-weight ratio.

- It’s corrosion-resistant and easy to surface finish (anodizing, polishing, or coating).

- It’s recyclable and environmentally friendly.

Compared to titanium or magnesium, aluminum offers a great cost-performance balance, making it ideal for both prototypes and production parts.

Common Grades for Aluminum Spare Parts

When you send us a drawing, you have to specify the alloy. Choosing the wrong grade is the most common mistake I see. Here’s the difference between the 3 grades we machine every day:

1. 6061-T6 (The Standard Workhorse)

- The Shop-Floor Nickname: “The Easy One.”

- What You Need to Know: This is the most popular, general-purpose alloy. It offers excellent strength and fantastic machinability. It’s also the best choice if your part needs to be welded.

- Best Used For: Brackets, frames, structural supports, and tooling plates. It’s the default choice unless your part is ultra-critical.

2. 7075-T6 (The Aerospace Fighter)

- The Shop-Floor Nickname: “The Strong One.”

- What You Need to Know: This is one of the highest-strength aluminum alloys available. It’s often compared to some steels in terms of strength-to-weight ratio.

- The Trade-Off: It’s more expensive, and because it’s so strong, it’s slightly trickier to machine and doesn’t weld well. We use this when strength and weight are non-negotiable (like in aerospace).

- Best Used For: High-stress parts, bicycle components, high-load linkages, and demanding defense applications.

3. 5052-H32 (The Sheet Metal Star)

- The Shop-Floor Nickname: “The Bendy One.”

- What You Need to Know: We rarely machine this from a thick block. 5052 has lower strength than 6061, but it has superior corrosion resistance (especially in saltwater environments) and excellent formability.

- Best Used For: Fuel tanks, marine components, and sheet metal parts that need to be bent or hydroformed after machining.

If you don’t nail the alloy choice, you’ve started the whole process on the wrong foot. The material grade directly determines the final performance—there’s no question about it. For in-depth information on CNC machining of aluminum alloys, please refer to our 👉Complete Guide to CNC Machining of Aluminum Alloys.

Surface Finish: The Final, Critical Step

A machined aluminum part is just bare metal. The finish is what makes it perform, resist corrosion, and look professional. Don’t skip this step.

1. Anodizing (Type II and Type III)

- What It Is: An electrochemical process that converts the surface of the aluminum into a durable, porous aluminum oxide layer. This layer is then sealed or dyed.

- Type II (Standard/Cosmetic): Used for color (black, red, blue) and moderate corrosion resistance. This is your standard electronic enclosure finish. Thickness: ~0.005mm to 0.025mm.

- Type III (Hardcoat): Thicker, much harder, and highly wear-resistant. Used for sliding or frictional parts. Thickness: ~0.025mm to 0.075mm. Engineers must factor Type III thickness into tolerances!

2. Chromate Conversion Coating (Chem Film)

- What It Is: A chemical dip (using Alodine or Iridite) that creates an extremely thin, conductive coating. It offers protection and a perfect base for paint.

- The Key Detail: Unlike anodizing, this coating is electrically conductive. If your spare part needs to ground static electricity or needs internal contact, this is your only choice.

3. Powder Coating

- What It Is: A dry powder applied electrostatically and then cured under heat.

- The Key Detail: Provides a thick, impact-resistant, and highly cosmetic layer. It’s often used when the part needs to match a specific industrial color palette or needs maximum outdoor durability.

Case Study: Precision Aluminum Enclosure for an Industrial Sensor Project

A European automation company contacted us to produce custom aluminum sensor housings for their new industrial monitoring system. The challenge: to achieve a lightweight, corrosion-resistant design with tight dimensional accuracy.

Project Details:

- Material: 6061-T6 Aluminum

- Part Size: 120 × 75 × 45 mm

- Tolerance: ±0.02 mm

- Surface Finish: Anodized matte black (10 µm thickness)

- Batch Size: 300 units

- Machining Process: 4-axis CNC milling + tapping + chamfering

- Functional Requirement: IP65 sealing and vibration resistance

Result: The components were machined and inspected using a coordinate measuring machine (CMM).

All parts met the required flatness within 0.03 mm and thread accuracy within 6H tolerance.

By optimizing the toolpath and reducing unnecessary tool changes, the cycle time per unit was cut down by 22%, saving the customer over $1,800 in machining time for the full batch.

The housings were later assembled successfully and passed the client’s field vibration and corrosion tests, confirming both design reliability and cost efficiency.

Aluminum Spare Parts in Practical Use

Aluminum CNC parts are everywhere — you’ll find them in:

- Automotive: Gearbox housings, brackets, and cooling components.

- Aerospace: Structural frames, fixtures, and instrument housings.

- Medical: Instrument handles, casings, and precision fittings.

- Electronics: Heat sinks, housings, and connector parts.

Because it’s easy to machine and finish, aluminum helps shorten production cycles and reduce post-processing costs.

Final Checklist for Your Aluminum Spare Parts

Before you submit your CAD model, always check these three things. This will speed up your quote and eliminate potential errors:

- Define the Finish FIRST: Don’t just call out “Anodize.” Specify Type II (Cosmetic) or Type III (Hardcoat). If your part needs to carry a current, specify Chem Film.

- Watch the Walls: Aluminum can warp easily, especially 7075. If you design walls thinner than 0.8mm, expect higher costs and longer lead times due to fixturing and slower cutting speeds.

- Use a Clean CAD File: Ensure your models are saved to STEP or IGES for the fastest, most reliable quote.

Conclusion:

Aluminum CNC machining continues to dominate because it offers the best mix of performance, precision, and affordability. For engineers or purchasing managers who need reliable suppliers for custom non-standard parts, aluminum is often the first and most logical choice.

At Allied Metal Solutions, we combine years of CNC experience with advanced inspection systems to deliver tight-tolerance aluminum parts — whether for prototypes or full-scale production runs.

If you have drawings ready or need advice choosing the right aluminum alloy and finish, we’re here to help you get it right the first time.

Ready to Cut Your Next Aluminum Component?

We’ll review your design, suggest the best machining approach, and provide a fast, accurate quote to fit your budget and timeline.