Need a uniform, non-directional finish on your machined parts? Raw machined surfaces can have visible tool marks and lack the aesthetic or functional texture your project requires.

Bead blasting is a surface finishing process that uses fine, spherical media propelled by compressed air to clean, polish, or texture a part's surface, resulting in a smooth, matte finish.

In my years running a CNC machine shop, I’ve learned that the final finish of a part is just as critical as its dimensional accuracy. For engineers designing high-end automation systems, the look and feel of a component can be just as important as its function. That’s where bead blasting comes in. Using fine beads to smooth, polish, or texture a surface, bead blasting is a versatile finishing method applied to metals, plastics, and even glass. It not only removes rust, paint, or debris but also creates a consistent, high-quality appearance. After decades in CNC machining, I’ve seen how the right surface treatment can save both time and cost, and bead blasting remains one of the most effective and reliable finishing processes for custom machined parts.

What is bead blasting?

What exactly is this process? How does shooting tiny beads at a part result in a beautiful, uniform surface finish?

Bead blasting is a process where a pressurized stream of fine media, typically glass or ceramic beads, is propelled at a surface to alter its finish without significantly removing material.

Diving Deeper into the Definition

Bead blasting is a type of media blasting1, which is a general term for any process that involves propelling a stream of abrasive material against a surface under high pressure. What makes bead blasting unique is the specific type of media it uses and the effect it has on the part.

Unlike other abrasive blasting methods that are designed to aggressively strip material, bead blasting is primarily a finishing process.

- The Media: It uses very small, spherical (round) media, most commonly glass beads. Because the particles are round instead of sharp and angular, they do not aggressively cut into the part's surface.

- The Action: Instead of eroding the surface, the impact of the beads creates a uniform pattern of tiny, microscopic dimples. This process, known as peening, smooths out imperfections, removes discoloration from processes like heat treating, and imparts a consistent, non-directional finish.

For an engineer like David, specifying a "bead blast finish" on a drawing tells a machinist like me that he wants a clean, smooth, matte, or satin surface, free of the directional tool marks left behind by the CNC machining process. It's an excellent and cost-effective way to create a high-quality cosmetic finish.

What is the process of bead blasting?

From a raw machined part to a finished component, what does the workflow look like? What are the key operational steps in a professional bead blasting process?

The bead blasting process involves thoroughly cleaning the part, placing it inside a sealed blast cabinet, propelling media with compressed air, and then performing a final cleaning to remove any residue.

Diving Deeper into the Workflow

Achieving a perfect bead blast finish requires a controlled and systematic process. It’s not as simple as just pointing a nozzle at a part. For a high-quality outcome that would meet David's standards, every step must be done correctly.

Here is a typical step-by-step breakdown of the process:

-

Surface Preparation and Cleaning:

- This is a critical first step. The part must be completely free of any oils, grease, coolant, or other contaminants. We typically use an ultrasonic cleaner or a solvent degreaser. Any residue left on the surface will be impacted into the part by the beads, resulting in a stained or uneven finish.

-

Masking (If Necessary):

- If there are any areas of the part that should not be bead blasted—such as critical bearing surfaces, threaded holes, or polished features—they are carefully masked off with heavy-duty tape or custom rubber plugs.

-

The Blasting Operation:

- The clean, masked part is placed inside a sealed blast cabinet2.

- The operator places their arms into sealed gloves built into the cabinet and holds the part under the blasting nozzle.

- Using a foot pedal to control the flow of compressed air, the operator moves the nozzle evenly across all surfaces of the part until a uniform finish is achieved.

-

Post-Blast Cleaning:

- After blasting, the part is covered in fine dust from the media. It is removed from the cabinet and thoroughly cleaned with compressed air to remove all loose particles.

- For critical applications, the part may be washed again to ensure it is completely free of any media residue before it moves to final inspection or assembly.

This controlled process ensures that the finish is consistent and that the part is clean and ready for its final application.

How do bead blasters work?

What is the equipment that performs this process? What are the main components of a bead blaster, and how do they work together to propel the media?

A bead blaster works by using a compressed air system to pull media from a hopper and accelerate it through a nozzle inside an enclosed cabinet, directing it at the workpiece.

Diving Deeper into the Equipment

The machine used for bead blasting is typically a self-contained unit called a blast cabinet. This design protects the operator from the ricocheting media and contains the dust that is generated. For an engineer like David, understanding the equipment helps in understanding the process's capabilities.

Here are the key components and how they function:

-

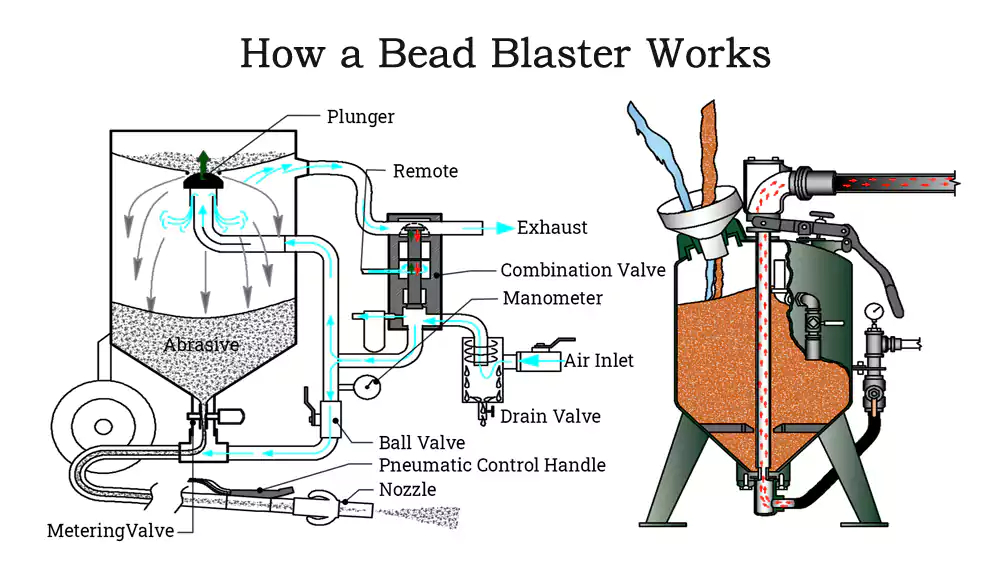

The Blast Cabinet: This is the main enclosure, usually made of steel. It has a viewing window for the operator, sealed arm ports with attached gloves, and internal lighting. It provides a safe, contained environment for the blasting process.

-

The Compressed Air System3: An external air compressor supplies a high volume of clean, dry, high-pressure air to the cabinet. The pressure (measured in PSI) is a key variable that the operator controls to adjust the intensity of the blasting action.

-

The Blasting Gun and Media Delivery System: This is how the beads are propelled. There are two main types of systems:

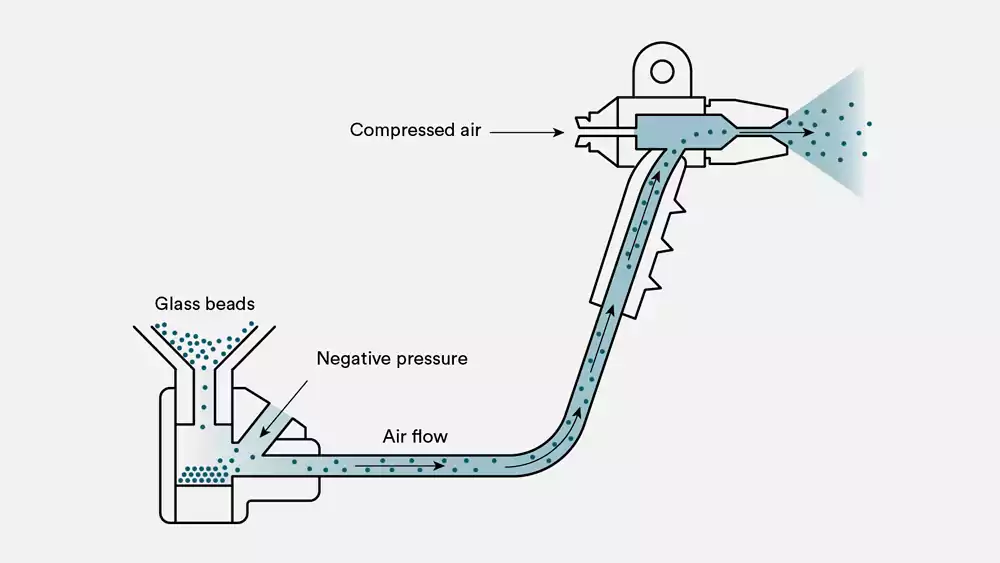

- Siphon-Fed System: This is the most common type for bead blasting. Compressed air is fed into a gun, creating a vacuum (the Venturi effect) that siphons the media up from a hopper at the bottom of the cabinet. The media mixes with the air stream inside the gun and is then accelerated out of the nozzle.

- Pressure-Fed System: In this system, the media is held in a pressurized pot. This allows the media to be delivered to the gun at a much higher velocity. This is a more powerful and aggressive system, often used for sandblasting.

-

The Media Reclaimer and Dust Collector: As the beads are used, they fall to a hopper at the bottom of the cabinet. A reclaimer system separates the usable, intact beads from the fractured media and dust. The good beads are returned to the hopper to be used again, while the dust is pulled into a separate dust collector to keep the cabinet's air clear.

What Media is Used in Bead Blasting?

Are all "beads" the same? What are the different types of spherical media used in bead blasting, and how do their properties differ?

The most common media used in bead blasting are glass beads, ceramic beads, and steel shot. Glass beads are for general finishing, while ceramic and steel offer greater durability and impact.

Diving Deeper into Blasting Media

The choice of media is the most important variable in any bead blasting operation. It directly determines the final surface finish, the aggressiveness of the process, and the cost. The term "bead blasting" specifically refers to the use of spherical media.

Here are the most common types:

-

Glass Beads:

- Description: Made from lead-free, soda-lime glass, these are the most common and versatile type of bead media.

- Characteristics: They are relatively soft and are used for cleaning, deburring, and creating a smooth, bright, satin finish. Because they are less aggressive, they are excellent for finishing softer metals like aluminum or brass without changing the part's dimensions. They are also chemically inert.

- Use: General-purpose finishing, cleaning, and light peening.

-

Ceramic Beads:

- Description: Made from materials like zirconium oxide, ceramic beads are much harder and more durable than glass beads.

- Characteristics: They have a very long life and can be recycled many more times than glass. They produce a very smooth, fine, satin finish and are excellent for peening applications to increase fatigue strength. They are more expensive than glass beads.

- Use: High-end finishing, surface hardening (peening), and cleaning tough contaminants.

-

Steel Shot:

- Description: Small, spherical pellets of steel.

- Characteristics: Steel shot is very hard, heavy, and aggressive. It is primarily used for heavy-duty cleaning and surface peening to improve metal fatigue life. It is not typically used for fine cosmetic finishing, as it can leave a rougher surface.

- Use: Heavy scale removal, surface preparation for coatings, and shot peening.

For most of the custom machined parts that David would design, glass beads are the standard choice for achieving a high-quality cosmetic finish.

How Does a Blasting Media Selection Chart Help?

With so many options, how do you choose the right media? How does a selection chart help you compare different types of blasting media for a specific job?

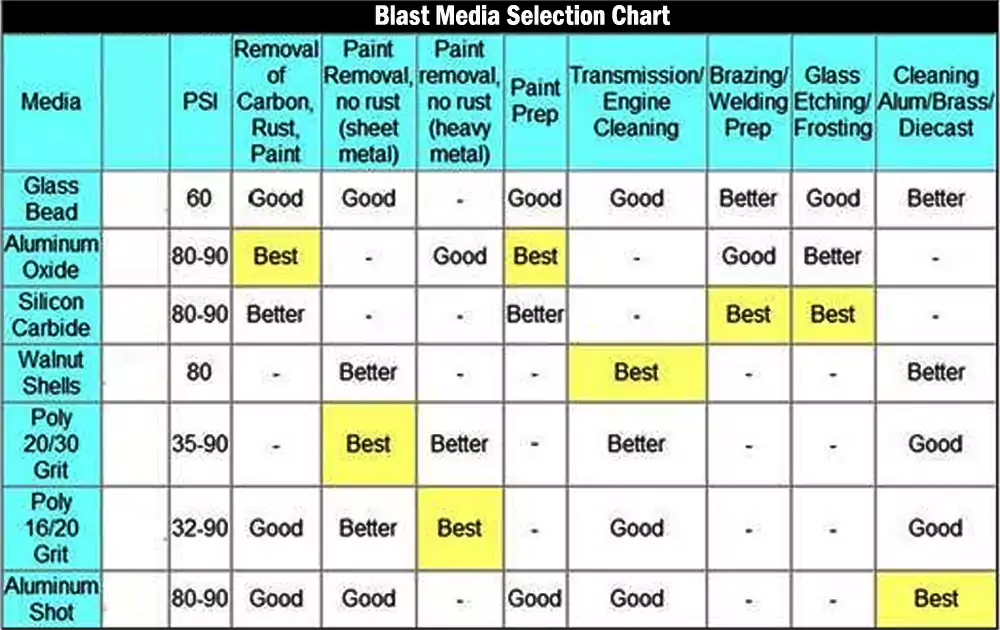

A blasting media selection chart helps you compare different media based on key properties like hardness, shape, and density. This allows you to choose the best media to achieve your desired surface finish.

Diving Deeper into Media Comparison

For an engineer like David, choosing a surface finish also involves understanding the media used to create it. A selection chart is a powerful tool for comparing the different options. It's important to include both round (beads) and angular media to understand the full spectrum of media blasting.

Here is a simplified media selection chart:

| Media Type | Shape | Hardness (Mohs) | Density | Aggressiveness | Resulting Finish |

|---|---|---|---|---|---|

| Glass Beads | Spherical | 5.5 - 6.0 | Low | Low | Bright, satin, or matte finish. Cleans without removing material. |

| Aluminum Oxide | Angular | 9.0 | High | Very High | Dull, etched matte finish. Aggressively removes material. |

| Steel Shot | Spherical | Varies | Very High | High | Smooth, peened finish. Good for cleaning and strengthening. |

| Silicon Carbide | Angular | 9.5 | High | Extremely High | Deeply etched matte finish. For very hard materials. |

| Plastic Media | Angular | 3.0 - 4.0 | Very Low | Very Low | Cleans and strips paint without damaging the substrate. |

| Walnut Shells | Angular | 3.0 - 4.0 | Very Low | Very Low | Cleans and polishes delicate parts without etching. |

How to Use the Chart:

- For a soft material like aluminum where you want a cosmetic finish without changing dimensions: Glass Beads are the ideal choice due to their low hardness and spherical shape.

- To strip heavy rust and scale off a steel part to prepare it for painting: Aluminum Oxide is the best choice because of its high hardness and angular shape, which provides an aggressive "bite."

- To strengthen the surface of a high-stress steel component: Steel Shot is used for shot peening.

This chart shows why "bead blasting" is a finishing process, while blasting with angular media like aluminum oxide is a stripping process.

When Should You Choose a Bead Blast Finish?

In what situations is bead blasting the best choice for a surface finish? When should an engineer like David specify a "Bead Blast Finish" on a drawing?

Choose a bead blast finish when you need to create a uniform, non-directional matte or satin appearance, clean a part without changing its dimensions, or gently blend machining marks.

Diving Deeper into the Application Decision

Specifying a surface finish is a key part of an engineering drawing. The choice to bead blast a part is made when specific aesthetic or functional goals need to be met.

Here are the most common reasons why an engineer like David would choose a bead blast finish:

-

To Achieve a Uniform, Cosmetic Finish:

- This is the most common reason. The CNC machining process, especially milling, can leave behind visible, directional tool marks. Bead blasting completely removes these marks and replaces them with a soft, uniform, non-directional matte or satin texture. This gives the part a clean, high-quality, finished look. It's excellent for parts like electronic enclosures or visible machine components.

-

To Clean or Deburr Without Damaging the Part:

- Bead blasting is an effective way to remove light burrs, discoloration from heat treating, or other surface contaminants. Because it is not very aggressive, it can perform this cleaning action without significantly removing the underlying material or altering the part's critical dimensions.

-

To Prepare a Surface for Another Coating:

- A bead blasted surface has a slightly textured profile, which can be an excellent surface for coatings like anodizing or paint to adhere to. The process cleans the surface and provides a "tooth" for the next coating to grip.

-

For Light Peening to Improve Fatigue Life:

- The impact of the beads creates a layer of compressive stress on the surface of the part. This process, known as peening, can help to close microscopic surface cracks and increase the part's resistance to fatigue failure. While steel shot is used for heavy-duty peening, glass beads can provide a light peening effect.

If the goal is to aggressively remove a heavy coating or a lot of rust, a more aggressive method like sandblasting would be chosen. But for finishing and light cleaning, bead blasting is ideal.

What's the difference between bead blasting and sandblasting?

These terms are often used interchangeably, but are they the same thing? What is the critical difference between bead blasting and the more well-known process of sandblasting?

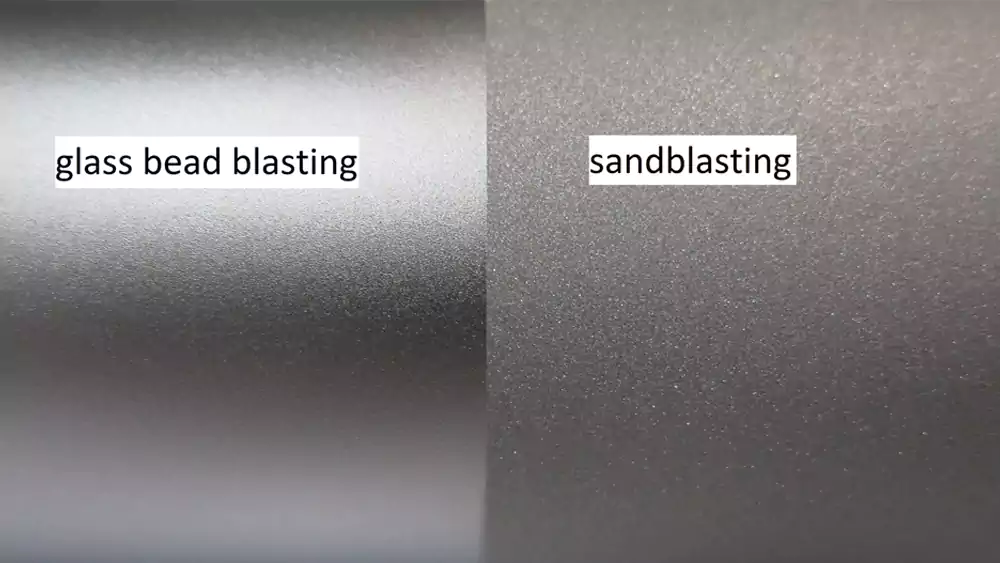

The main difference is the media. Bead blasting uses round, spherical media (like glass beads) for a smooth finish. Sandblasting uses sharp, angular media (like sand or aluminum oxide) for aggressive stripping.

Diving Deeper into the Comparison

This is the most important distinction in the world of media blasting, and for an engineer, using the right term is critical. While both processes use compressed air to propel media, their purpose and results are completely different.

Here’s a head-to-head comparison:

| Feature | Bead Blasting | Sandblasting |

|---|---|---|

| Media Used | Spherical (round) media, like glass beads. | Angular (sharp) media, like sand, aluminum oxide, or silicon carbide. |

| Action on Surface | It peens the surface. The round beads create a pattern of tiny dimples, smoothing the surface. | It etches or erodes the surface. The sharp particles act like tiny chisels, cutting into the material. |

| Material Removal | Minimal to none. It is a finishing process designed to clean and texture the surface without significantly changing its dimensions. | Significant. It is an aggressive stripping process designed to remove material, such as heavy rust, paint, or scale. |

| Primary Purpose | Finishing. Used to create a smooth, consistent, matte, or satin cosmetic finish. | Stripping. Used to remove heavy coatings and prepare a surface for a new coating. |

| Resulting Surface | A smooth, often bright, non-directional satin or matte finish. | A rough, dull, heavily etched matte finish. |

| Common Analogy | It's like using a fine polishing compound. | It's like using coarse sandpaper. |

In my shop, we would bead blast a brand new, precision machined aluminum housing to give it a beautiful, uniform look for a client like David. We would sandblast a rusty old steel bracket to strip it down to bare metal before painting it. Using the wrong term on a drawing could result in a part being accidentally damaged by an overly aggressive process.

Continue reading to explore more differences between bead blasting and sandblasting.

What are the Properties of a Bead Blast Surface Finish?

What does a bead blasted surface actually look and feel like? What are the key characteristics of the finish that this process creates?

A bead blast surface finish has a uniform, non-directional, and non-reflective matte or satin texture. It is smooth to the touch and effectively hides fingerprints and small imperfections.

Diving Deeper into the Finish Characteristics

When David specifies a bead blast finish, he is calling for a very specific set of surface properties. The finish is valued for both its aesthetic appeal and its functional benefits.

Here are the key properties of a bead blasted surface:

-

Uniform and Non-Directional:

- This is its most important visual characteristic. Unlike a brushed or machined finish, which has clear, directional lines, a bead blast finish has a completely random, homogenous texture. The surface looks the same from every angle.

-

Matte or Satin Appearance:

- The microscopic dimples created by the beads diffuse light rather than reflecting it directly. This results in a non-reflective, low-sheen finish. The exact appearance can range from a soft, frosted matte to a brighter, richer satin, depending on the media size and blasting pressure used.

-

Smooth to the Touch:

- While the surface is textured on a microscopic level, it feels very smooth and consistent to the touch. The process is excellent at blending and hiding the tool marks left behind by CNC milling or turning.

-

Hides Imperfections:

- The soft, matte texture is very effective at hiding fingerprints, smudges, and minor surface scratches that would be very obvious on a polished or brushed surface. This makes it a very practical finish for parts that will be handled frequently.

-

Clean and Free of Contaminants:

- The process itself is a cleaning operation. A properly bead blasted and cleaned part is free of any oils, discoloration, or light burrs, making it ready for immediate use or for a secondary finishing process like anodizing.

The combination of these properties makes bead blasting one of the most popular and versatile surface finishes for high-quality custom machined parts.

What Are the Applications of Bead Blasting?

Where is bead blasting used in the real world? What are some common examples of parts and industries that rely on this versatile surface finish?

Bead blasting is widely used to finish parts in the automotive, aerospace, medical, and electronics industries for applications like creating cosmetic finishes on enclosures, cleaning engine parts, and texturing surgical tools.

Diving Deeper into Real-World Applications

The versatility of bead blasting means it is used across a huge range of industries for many different purposes. For an engineer like David, who works in automation, many of these applications are directly relevant.

Here are some of the key industrial applications:

-

- This is a primary application in my world. We bead blast custom machined aluminum enclosures, faceplates, and housings to give them a premium, Apple-like matte finish. It's also used on steel and stainless steel components to provide a clean, uniform look.

-

Automotive Restoration:

- Bead blasting is essential in the restoration of classic cars and motorcycles. It is used to gently clean engine components like intake manifolds, valve covers, and transmission cases, removing decades of grime and corrosion without damaging the underlying aluminum or steel.

-

- Surgeons' tools and other medical instruments are often bead blasted. The resulting non-reflective matte finish reduces glare under bright operating room lights. The smooth, cleanable surface is also a major benefit.

-

- In the aerospace industry, bead blasting is used for cleaning and deburring critical components. It is also used as a surface preparation step before applying specialized coatings or for shot peening to improve the fatigue life of a part.

-

Mold and Die Cleaning:

- The cavities of plastic injection molds and other tooling can be gently cleaned with bead blasting to remove residue and contaminants without damaging the delicate, polished surfaces of the mold itself.

In all these examples, bead blasting is chosen for its ability to produce a high-quality finish in a controlled and repeatable way.

Common Bead Blasting FAQs

When I discuss finishing options with clients like David, they often have very practical questions about the bead blasting process. Here are the answers to some of the most common ones.

Does bead blasting remove material?

Generally, no. When done correctly with the proper media (like glass beads) and at the right pressure, bead blasting is considered a non-destructive finishing process. Its primary action is peening, not erosion. It will not significantly change the dimensions or tolerances of a precision machined part. However, if done very aggressively or for a very long time, a microscopic amount of material could be removed, but this is not its purpose.

Is bead blasting safe for all materials?

It is safe for most metals, including aluminum, steel, stainless steel, brass, and titanium. It can also be used on some harder plastics. However, it is generally not suitable for very soft materials like rubber or soft plastics, as the impact could damage them.

Can you bead blast a part that has been anodized?

Yes, bead blasting is very commonly used as a pre-treatment before anodizing. Blasting the raw aluminum part first creates a soft, matte texture. When this part is then anodized, the result is a beautiful, non-reflective matte anodized finish, which is very popular for high-end electronics and machine components.

How much does a bead blast finish cost?

Bead blasting is generally a very cost-effective finishing process. The cost is based on the labor time it takes to process the part. Therefore, the cost is influenced by the part's size and complexity. A large, complex part that is difficult to handle and requires careful masking will cost more to blast than a small, simple part.

Does bead blasting change part dimensions?

The change is negligible, typically less than 0.001 inches (0.025 mm). It peens the surface rather than cutting it away, making it safe for most precision-machined components.

Conclusion

Bead blasting is a versatile and cost-effective method for achieving a high-quality, uniform matte finish. It cleans, deburrs, and textures parts without damaging their critical dimensions.

-

Understanding media blasting can enhance your knowledge of various surface finishing techniques and their applications. ↩

-

Explore this link to understand the functionality and benefits of a blast cabinet in achieving a perfect bead blast finish. ↩

-

Learn about the role of a Compressed Air System in bead blasting, essential for controlling the blasting intensity. ↩

BetPK55… yeah, I’ve tried it. Found some okay deals there. The platform’s alright, not the flashiest, but it gets the job done. See what you think though: betpk55