Facing confusion between CNC milling and turning? You're not alone. Many engineers struggle to pick the right process. Let me clarify this using my 15+ years in machining.

CNC milling uses rotating tools to cut stationary material, perfect for complex shapes. CNC turning rotates material against fixed tools, ideal for cylindrical parts like shafts. Each method suits specific part geometries and production needs.

Understanding these differences saves time and money. I've seen projects delayed by choosing the wrong method. Let me break down each process so you can make informed decisions.

What is CNC turning?

Struggling with cylindrical parts? Turning could be your solution. Many waste money using milling for round components. I learned this early in my career.

CNC turning holds material in a rotating chuck while stationary tools cut it. This creates symmetrical round parts like bolts or pulleys efficiently. It's faster and cheaper than milling for axisymmetric geometries.

Lathe Turning Process

Turning transformed how I produce rotational parts. At Allied Metal, we handle turning jobs daily. Now let's examine its key aspects.

Core mechanics of turning

The workpiece spins while cutting tools move linearly. This setup achieves:

- High concentricity for round features

- Excellent surface finish on diameters

- Tight tolerances (±0.005" typical)

Ideal materials for turning

| Material Type | Examples | Why It Works |

|---|---|---|

| Metals | Aluminum, Steel, Brass | Machines smoothly with good chip control |

| Plastics | PEEK, Nylon, Acetal | Minimal tool pressure prevents deformation |

| Composites | Phenolics, G10 | Handles abrasive materials effectively |

When I recommend turning

I always choose turning for:

- High-volume round parts (500+ units)

- External grooves and threads

- Boring internal diameters

- Tapered geometries like nozzles

One client saved 30% by switching from milling to turning for hydraulic fittings. The cycle time dropped from 8 minutes to 90 seconds per part.

Click to learn more about CNC turning or get a turning part?

What is CNC milling?

Need complex non-round parts? Milling solves this. I've watched engineers force turning on unsuitable parts. Don't make that mistake.

CNC milling moves rotating tools across stationary material to create flat surfaces, slots, and 3D contours. It machines complex shapes that turning cannot achieve, like engine blocks or brackets with multiple angles.

Milling Complex Shapes

Milling opened new possibilities for my business. When we added 5-axis mills, prototype complexity skyrocketed. Let's explore its capabilities.

Why milling excels for complexity

Multi-axis milling machines can:

- Cut from any angle

- Produce undercuts and cavities

- Machine irregular surfaces

- Combine operations in one setup

Key milling operations

| Operation | Function | Common Uses |

|---|---|---|

| Face Milling | Flattening surfaces | Mounting plates, sealing surfaces |

| Pocketing | Creating enclosed cavities | Housings, enclosures |

| Profiling | Cutting external shapes | Brackets, frames |

| Drilling/Tapping | Adding holes | Assembly points, fluid passages |

Material considerations

Milling handles challenging materials1 like titanium better than turning. The stationary workpiece avoids vibration issues2 during interrupted cuts. For a robotics client, we milled titanium joints that turning couldn't process without chatter.

Difference between CNC turning and CNC milling?

Confused about which process fits your part? Choosing wrong wastes budget. I've fixed many costly mistakes from this confusion.

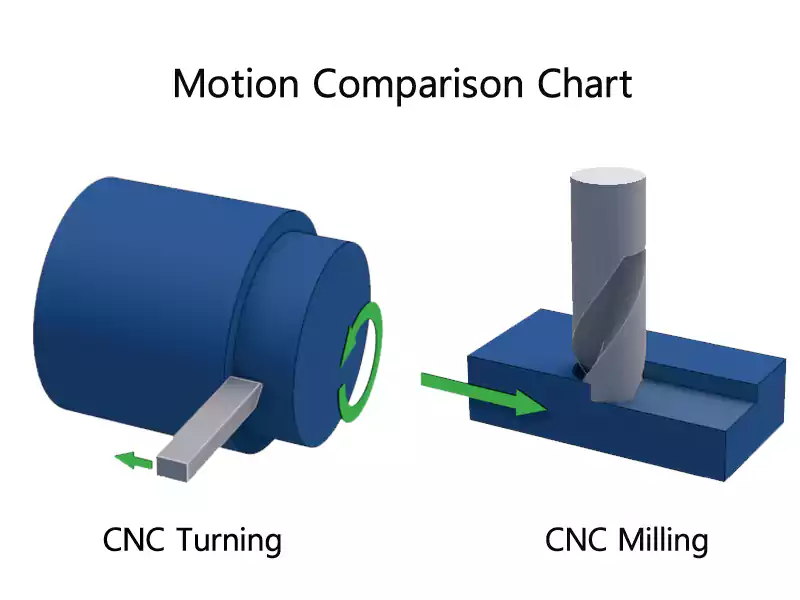

Turning rotates the workpiece against stationary tools for cylindrical parts. Milling moves rotating tools around stationary material for complex shapes. The fundamental difference lies in what moves - the workpiece or the cutting tool.

Tool vs Workpiece Movement

This movement difference impacts everything. Let me clarify the practical distinctions I share with clients.

Direct comparison table

| Factor | CNC Turning | CNC Milling |

|---|---|---|

| Part Movement | Rotates | Stationary |

| Tool Movement | Linear paths | Multi-axis movement |

| Best For | Radial symmetry | Complex contours |

| Setup Time | Faster (minutes) | Slower (15-30+ mins) |

| Cost Efficiency | Higher for round parts | Better for complex shapes |

| Surface Finish | Superior on diameters | Better on flat surfaces |

Real-world examples

- Turning: Created 10,000 brass fittings in 2 days

- Milling: Produced aluminum sensor mounts with 37 angled features

Tolerance differences

While both achieve tight tolerances, turning consistently delivers better roundness. Milling maintains tighter positional accuracy between features. For a medical device, we combined both processes - turned the main body then milled side ports.

Is milling the same as turning?

Assuming these processes are interchangeable? That's dangerous. I've seen projects fail from this misconception.

No, milling and turning are fundamentally different processes. Turning creates rotationally symmetric parts by spinning material. Milling creates complex geometries using multi-axis tool movement. They serve distinct purposes in manufacturing.

Milling and Turning Differences

Understanding this prevents costly errors. Let me explain why they're not substitutes.

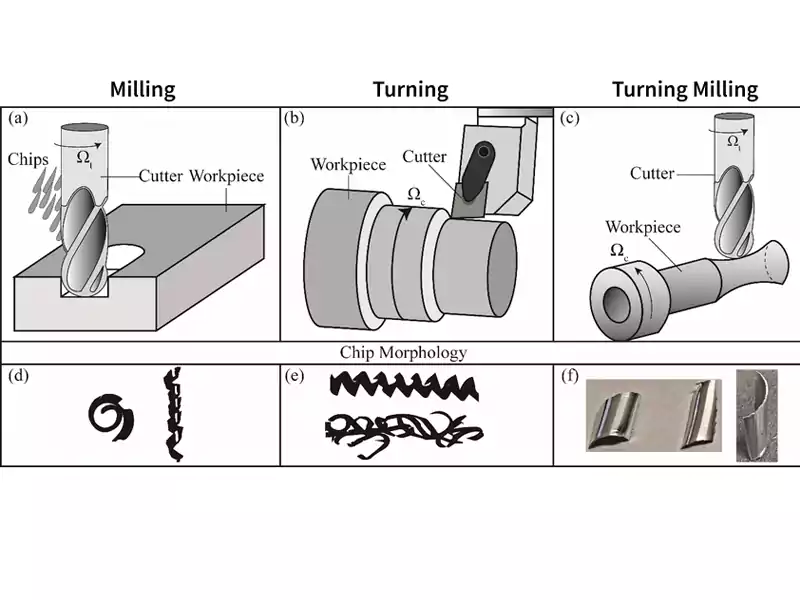

Key operational differences

- Workholding: Turning uses chucks, milling uses vises/fixtures

- Tooling: Turning tools are single-point, milling uses multi-tooth tools

- Motion: Turning = 2-axis (X,Z), Milling = 3-5+ axes

Cost impact analysis

Using the wrong process increases costs by:

- Longer machining time

- Higher tool wear

- More scrap parts

- Additional setups

A recent automation project saved $18k by switching bracket production from turning to milling. The complex angles were impossible to turn efficiently.

Material removal rates

- Turning removes material faster for simple diameters

- Milling removes material faster for pockets and slots

- Aluminum removal rate example:

- Turning: 15 in³/min

- Milling: 8 in³/min (but handles complex features)

When to use milling vs turning?

Choosing between milling and turning? Your part geometry decides. I guide clients through this daily.

Use turning for cylindrical, conical, or radially symmetric parts like shafts. Choose milling for prismatic shapes with complex features like brackets or housings. Many projects require both processes for different components.

Milling and Turning Applications

Making the right choice impacts quality and cost. Let me share my decision framework.

Selection criteria

Consider these factors:

- Part geometry: Round = turning, Complex = milling

- Volume: High volume favors turning

- Features: Threads/grooves = turning, Pockets/slots = milling

- Material: Brittle materials often mill better

Hybrid approach benefits

Many parts need both:

- Turn main body first

- Mill secondary features after

- Example: Valve body with turned ports and milled mounting flanges

Cost comparison scenarios

| Part Type | Best Process | Cost Savings |

|---|---|---|

| Drive shaft | Turning | 40% vs milling |

| Gear housing | Milling | 60% vs turning |

| Flanged connector | Both | 25% vs single process |

We recently combined both processes for drone motor mounts - turned the base cylinder then milled mounting arms. Cycle time dropped 35%.

Below is a real-life case we processed several years ago:

Case Study: Manufacturing a Turbocharger Impeller Shaft

- Action: The machine rotates the bar at high speed while a cutting tool shapes it.

- Result: We machine the main shaft, the stepped diameters for the bearings, and the threads on the end. At this point, the part is perfectly cylindrical.

Stage 2: CNC Milling (Adding the Complex Features)

Next, the turned part is moved to a 5-axis CNC mill to create the non-cylindrical features.

- Action: The machine uses a rotating tool (an end mill) to cut the stationary part.

- Result: We mill the flat face of the flange, cut the curved weight-reduction pockets, and drill the precise mounting holes.

The final part could not have been made with only one process. CNC turning efficiently created the shaft's round profile, while CNC milling was essential for adding the complex geometric features. This combination is key to modern manufacturing.

Require Milling vs. Turning? Allied Metal Can Handle Both

Need both milling and turning capabilities? Many shops specialize in only one. We eliminate that limitation.

Allied Metal provides complete CNC milling and turning services under one roof. Our 15+ machines handle everything from prototype to production. You get consistent quality without supplier juggling.

Milling and Turning Services

We've solved countless sourcing headaches. Let me show how our approach benefits you.

Our technical advantages

- Combined operations: Reduced handling errors

- Shared quality system: Identical inspection protocols

- Material synergy: Single material sourcing

- Faster turnaround: No inter-factory shipping

Equipment capabilities

| Process | Machines | Size Capacity | Tolerances |

|---|---|---|---|

| Turning | 8 CNC lathes | Ø24" x 40" | ±0.0005" |

| Milling | 7 CNC mills | 40" x 20" x 25" | ±0.001" |

| Multi-Task | 2 Turn-Mill | Ø15" x 30" | ±0.0007" |

Confidentiality assurance

We protect your designs with:

- Encrypted file transfers

- NDAs for all staff

- Isolated project workspaces

- No third-party subcontracting

One robotics client accelerated development by 6 weeks using our combined services. We machined 284 parts across both processes in 10 days.

Conclusion

Choose milling for complex shapes, turning for cylindrical parts. Many projects require both. Partner with experts who offer complete capabilities.