Table of Contents:

Explore CNC Machining Services: A Practical Guide to Processes and Capabilities

- November 9, 2024

- Tony

- Last updated on November 13, 2025 by Lucy

After twenty years in precision machining, I’ve learned that understanding CNC processes isn’t just technical knowledge – it’s business intelligence. Here’s what actually matters when you’re sourcing machined components.

1. The CNC Processes That Drive Modern Manufacturing

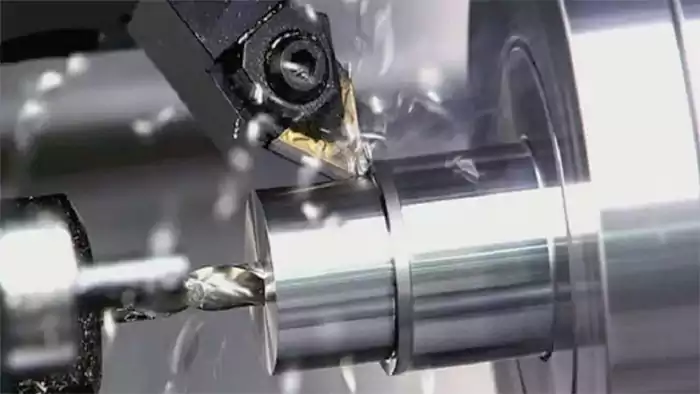

CNC Turning - For Round Parts That Matter

When your design calls for cylindrical components, turning is your answer. The workpiece rotates while stationary cutting tools remove material.

Common Applications:

- Shafts and bushings

- Valve components

- Fasteners and fittings

- Hydraulic components

Our Typical Tolerances:

- Diameter: ±0.01mm

- Concentricity: 0.02mm TIR

- Surface finish: Ra 0.8μm

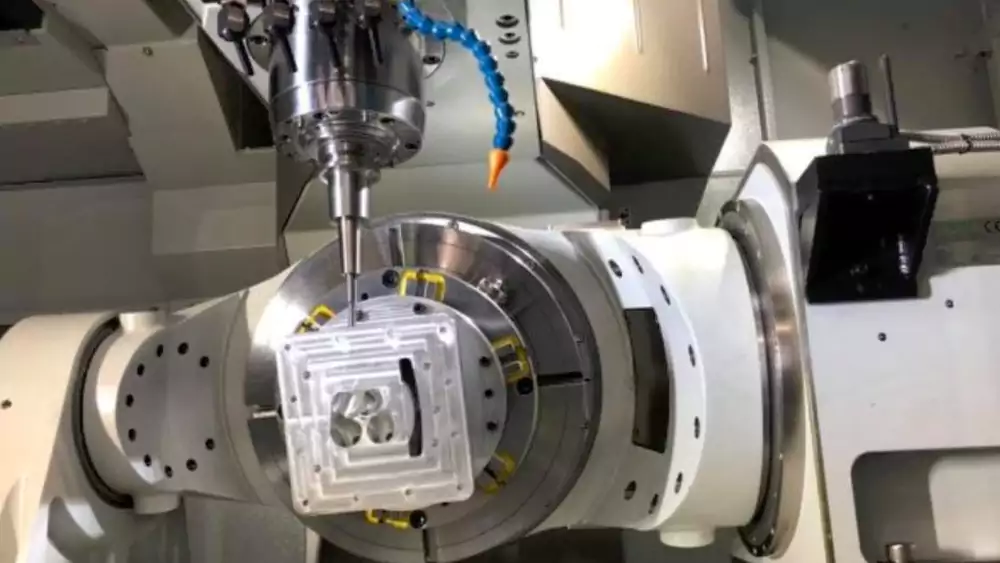

CNC Milling - Complexity Made Simple

From simple brackets to complex enclosures, milling handles geometries that would be impossible with manual methods.

| Milling Type | Best For | Our Capabilities |

|---|---|---|

| 3-Axis | Basic contours, flat surfaces | ±0.05mm positioning |

| 4-Axis | Complex contours, indexed features | Simultaneous rotary motion |

| 5-Axis | Complex 3D shapes, reduced setups | ±0.025mm full contouring |

Secondary Processes That Complete the Picture

Grinding

When you need mirror finishes or super tight tolerances

- Surface grinding: Flatness to 0.005mm

- Cylindrical grinding: Roundness within 0.0025mm

EDM (Electrical Discharge Machining)

- Perfect for hard materials (up to 65 HRC)

- Complex internal features

- No cutting forces on delicate parts

Laser Cutting

- Sheet metal up to 20mm thick

- ±0.1mm positional accuracy

- No tooling costs for prototypes

2. Material Selection: Matching Properties to Purpose

| Material | Best For | Key Considerations |

|---|---|---|

| 6061 Aluminum | General purpose, good strength-to-weight | Excellent machinability, anodizes well |

| 7075 Aluminum | High-strength applications | More challenging to machine, superior strength |

| 304 Stainless | Corrosion resistance, food grade | Work hardens - requires sharp tools |

| 316 Stainless | Marine, chemical applications | More difficult to machine than 304 |

| Carbon Steel | Structural components, wear parts | Requires corrosion protection |

| Titanium | Aerospace, medical implants | Low thermal conductivity - challenging machining |

| Plastics (Delrin, Nylon) | Electrical insulation, wear parts | Heat management critical during machining |

📌Case Study: Automotive Transmission Bracket

The Challenge: A tier-one automotive supplier needed 15,000 transmission mounting brackets in 10 weeks. The part required multiple machining operations and had to withstand engine vibration.

Material: 6061-T6 Aluminum

Manufacturing Process Breakdown:

- CNC Milling (5-Axis)

- Primary material removal

- Complex contouring for weight reduction

- Mounting surface finishing to Ra 1.6μm

- CNC Turning

- Bushing bore finishing to H7 tolerance

- Threading for M12 mounting bolts

- Secondary Operations

- Deburring and edge breaking

- Anodizing per MIL-A-8625

- Laser marking for traceability

Quality Results:

- First-article inspection: 100% to print

- Production yield: 99.8%

- Dimensional consistency: CpK > 1.67

- Delivery: 2 weeks ahead of schedule

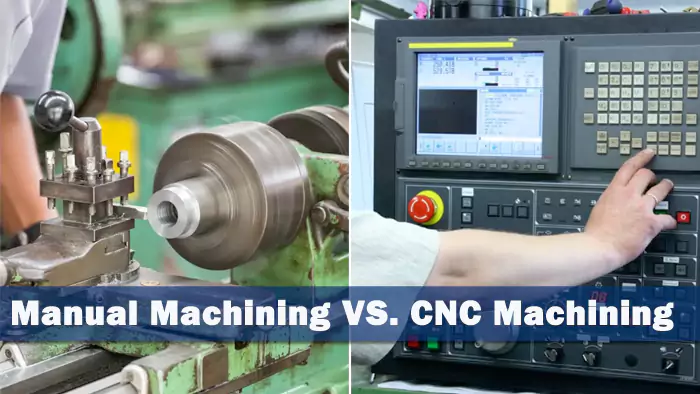

3. Why CNC Beats Conventional Machining Every Time

Precision You Can Count On

- Manual machining: Typically ±0.1mm

- CNC machining: Routinely ±0.025mm

- High-precision CNC: Down to ±0.005mm

Repeatability That Scales

- Manual: Operator-dependent results

- CNC: Identical parts from first to thousandth

Complex Geometry Made Practical

- 5-axis simultaneous machining

- Undercuts and complex contours

- Consistent results across production runs

4. Matching Processes to Your Production Needs

| Production Scenario | Recommended Approach | Key Benefits |

|---|---|---|

| Prototypes (1-10 pcs) | 3/5-axis milling, turning | Fast turnaround, design validation |

| Low volume (10-500 pcs) | CNC machining with soft jaws | Cost-effective tooling, quick changes |

| Medium volume (500-5,000 pcs) | Dedicated fixtures, optimized toolpaths | Reduced cycle times, consistent quality |

| High volume (5,000+ pcs) | Automated cells, pallet systems | Maximum efficiency, minimal operator intervention |

5. Quality Assurance: Beyond Basic Measurements

First-Article Inspection

- Full dimensional validation

- Material certification

- Surface finish verification

- Functional testing when required

In-Process Controls

- Statistical process control (SPC)

- Tool wear monitoring

- Automated probing

- Regular process audits

Final Inspection

- CMM for complex geometries

- Functional gaging for critical features

- Surface roughness testing

- Documentation package with every shipment

6. Making the Right Choice: Process Selection Guidelines

For Simple Geometries:

- Start with 3-axis milling or basic turning

- Consider material availability and machinability

- Evaluate secondary processing needs

For Complex Components:

- 5-axis machining reduces setups

- Consider splitting complex parts into simpler assemblies

- Evaluate trade-offs between machining time and part count

For High-Volume Production:

- Design for manufacturability analysis

- Process optimization for cycle time reduction

- Automated inspection integration

Conclusion

Good machining isn’t just about having the right equipment – it’s about knowing which process to use when. The difference between a good part and a great one often comes down to process selection and execution.

Ready to Optimize Your Next Project?

Send me your drawings – I’ll provide specific process recommendations and honest pricing based on twenty years of machining experience.