Product development too slow? Need parts faster? Rapid mold manufacturing offers speed without losing quality getting your ideas to market quickly.

Rapid mold manufacturing is a quick way to create molds. This is great for prototypes or small production runs helping you test designs or launch products fast.

I've seen how fast things need to move in this industry. When I first started my own shop Allied Metal getting prototypes quickly for clients was a huge challenge. Traditional methods were just too slow. That's when I really dug into rapid mold manufacturing. It felt like finding a secret weapon. It helped my clients get their products off the ground faster and honestly it was a big part of how I built my business. If you're looking to speed up your development cycle without breaking the bank or waiting forever then understanding this process is key. Let's explore what it's all about and how it can help you.

What Exactly is Rapid Mold Manufacturing?

Confused by industry jargon? Need a clear definition? Rapid mold manufacturing simplifies making molds getting your designs into physical parts quicker than ever.

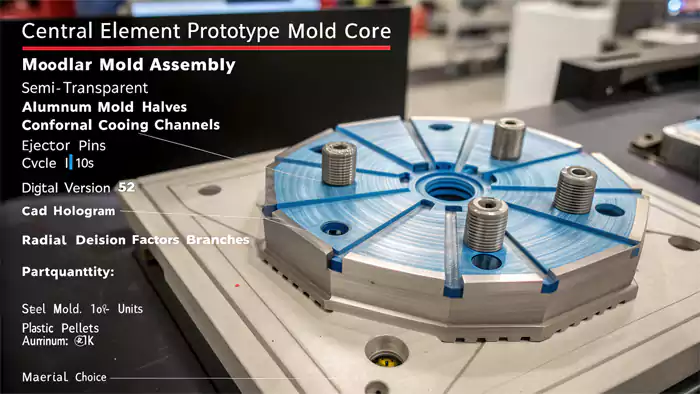

Rapid mold manufacturing uses advanced tech like 3D printing and CNC machining to create molds fast. This is ideal for prototypes or limited production runs.

When I first heard "rapid mold manufacturing" I pictured something complex. But it's actually straightforward. It's all about using modern techniques to make molds much faster than the old ways. Think about the traditional process – it could take weeks sometimes months. For a mechanical engineer like David who's under pressure to get new industrial automation systems1 out that kind of timeline is a killer. Rapid mold manufacturing cuts that time down dramatically.

We use things like:

- 3D Printing (Additive Manufacturing): We can directly print some types of molds or components for molds using robust plastics or even metal powders. This is super fast for complex shapes. I remember a client needing a tricky part for a robotic arm. We 3D printed a prototype mold in days not weeks. This saved them so much time.

- High-Speed CNC Machining: For metal molds especially aluminum modern CNC machines can cut incredibly fast and accurately. We optimize tool paths use the best cutters and sometimes automate the process to shave off even more time. This precision is vital for David when he's designing components that need to fit perfectly. The speed here is a game-changer.

The core idea is speed and efficiency getting a usable mold in your hands so you can start producing parts. It's not always for massive production runs of millions of parts but for that crucial stage of prototyping testing and early market entry2 it's a lifesaver. It truly has been a game changer in my experience at Allied Metal.

What's Involved in the Rapid Mold Manufacturing Process?

Facing tight deadlines? Need a streamlined workflow? The rapid mold process is designed for speed turning your digital designs into physical molds efficiently.

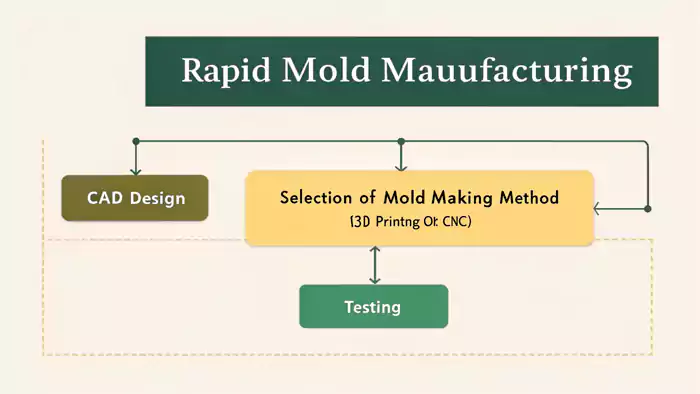

The process starts with your CAD design. Then we choose the best rapid method (like 3D printing or CNC) create the mold and test it.

David as a Lead Mechanical Engineer you know how critical a smooth process is. You send over your precise CAD files and that's where we kick things off. Here’s a typical flow I use at Allied Metal:

- Design Review & Consultation: First we look at your design. What material are you planning to inject? What are the tolerances? How many parts do you need? This helps us pick the best rapid tooling approach. I often chat with engineers like David at this stage to make sure we're on the same page about the part's end-use. Clear understanding here prevents headaches later.

- Mold Design for Manufacturability (DFM): We might suggest small tweaks to your part design to make it easier and faster to mold. Things like draft angles wall thickness or undercuts. This isn't about changing your core design but optimizing it for the rapid mold. This step is about collaboration for the best outcome.

- Tooling Method Selection: Based on complexity material and quantity we decide: Is it a 3D printed mold? Or a CNC machined aluminum mold? Maybe a hybrid approach? For instance if David needs a few dozen parts in a tricky material for a new automation system component an aluminum mold might be perfect. Matching the method to the need is key.

- Mold Creation: This is where the "rapid" part happens. Our machines get to work. Whether it's a 3D printer layering material or a CNC mill cutting metal it's much faster than traditional steel tool making. I still get excited seeing a mold come together so quickly.

- Testing & First Shots: Once the mold is ready we produce the first sample parts. We check them against your specs. If adjustments are needed we make them quickly. This iterative process is much faster with rapid molds.

The goal is to get you quality parts for testing or small production runs as fast as possible helping you meet those tight project deadlines.

What Different Types of Rapid Molds Are Available?

Need the right tool for the job? Unsure which mold type fits? Understanding rapid mold types helps you choose wisely for your specific project.

Common types include 3D printed molds (for quick prototypes) and machined aluminum molds (for higher quantities or tougher materials). Soft steel molds offer a middle ground.

Choosing the right type of rapid mold is crucial and it really depends on what you're trying to achieve David. It's like picking the right tool from your toolbox. Here are the main ones I work with:

Common Rapid Mold Types

| Mold Type | Material Used | Best For | Lifespan (Typical) | Lead Time |

|---|---|---|---|---|

| 3D Printed Molds | Photopolymers, Nylons | Very quick prototypes, complex geometries | 10–100+ parts | Days |

| Aluminum Molds | Aluminum Alloys | Prototypes, bridge tooling, low-volume runs | 500–10,000+ parts | 1–4 weeks |

| Soft Steel Molds | Pre-hardened Steel | Higher-volume prototypes, more abrasive resins | 10,000–100,000+ parts | 3–6 weeks |

| Hybrid Molds | Combination | Complex features, specific needs | Varies | Varies |

For David's work in industrial automation where parts might need good strength and precision aluminum molds are often the sweet spot for prototypes and early production. They offer a good balance. If it's just a handful of parts to test a concept a 3D printed mold could be even faster. It’s all about matching the mold type to your project's specific needs – part quantity material complexity and how quickly you need them. I always advise clients to think about the end goal of the prototype to make the best choice.

What's the Difference Between Rapid Mold Making and Rapid Prototyping?

Terms confusing? Need clarity on processes? Understanding these differences helps you select the right service for your product development stage effectively.

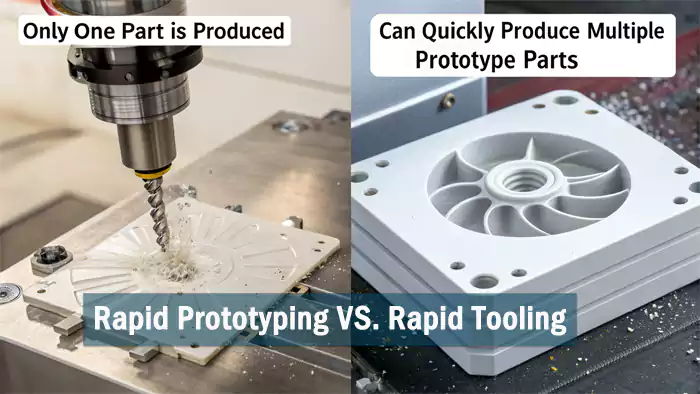

Rapid prototyping creates a single part (e.g. 3D printing). Rapid mold making creates a tool (the mold) to produce multiple prototype parts quickly.

This is a point that sometimes confuses people but it's a key distinction especially for engineers like David who are deeply involved in product development. Let me break it down simply:

- Rapid Prototyping: This is about making a prototype part directly. Think of 3D printing a single component or CNC machining a one-off piece from a block of material. You get the part itself. At Allied Metal we do a lot of 3D printing for rapid prototypes. It’s great for quickly checking a design's form fit and sometimes function. David might use this to get a physical feel for a new robot gripper design. You hold the actual prototype.

- Rapid Mold Making (Rapid Tooling): This is about making the tool (the mold) quickly. Once you have that mold you can then produce multiple identical prototype parts using processes like injection molding. So you're not making the part directly with the rapid process; you're making the thing that makes the parts. This tool then produces your parts.

Key Differences Summarized

| Feature | Rapid Prototyping (e.g. Direct 3D Printing) | Rapid Mold Making (then Injection Molding) |

|---|---|---|

| Output | One or few prototype parts | A mold (tool) |

| Part Production | Direct creation of part | Mold used to create multiple parts |

| Best For | Form/fit check very early designs one-offs | Testing with production material small runs |

| Materials | Often prototype materials (e.g. 3D print resins) | Can use actual production-intent plastics |

| Per-Part Cost | Higher for more than a few parts | Lower for small to medium batches |

I had a client who kept ordering 3D printed prototypes of the same part dozens of them. I explained that for that quantity it would be more cost-effective and faster overall to make a rapid aluminum mold. They could then get parts in the actual production material too. It was a lightbulb moment for them. For David if he needs 50 units of a specialized bracket3 to test across several machines rapid mold making is likely the better route than 3D printing each one individually. Understanding this difference saves time and money.

What Are the Key Advantages of Using Rapid Mold Making?

Facing slow development cycles? High prototype costs? Rapid mold making speeds up time-to-market and reduces initial expenses helping you innovate faster.

Key benefits include faster lead times lower initial costs for molds ability to test with production materials and design flexibility for quick iterations.

For any company trying to stay ahead especially in fields like industrial automation the advantages of rapid mold making are pretty clear. I've seen these benefits firsthand with many clients at Allied Metal. David you'd likely appreciate these points:

- Speed Speed Speed: This is the big one. Traditional steel molds can take months. A rapid mold especially an aluminum or 3D printed one can be ready in days or a few weeks. This means you get parts for testing or for your first small production run much faster. For a project with tight deadlines this is gold. I remember a project where we turned around a mold in 10 days allowing the client to showcase their new product at a trade show they thought they'd miss. Time is money in this business.

- Lower Upfront Costs: Creating a hardened steel production mold4 is a significant investment. Rapid molds are much less expensive to produce initially. This lowers the financial risk of testing a new design5. If the design needs changes you haven't sunk a fortune into the first tool. This accessibility is key for innovation.

- Test with Real Materials: While 3D printing is great for form and fit sometimes you need to test parts made from the actual production plastic. Rapid injection molding allows you to do this. You get insights into material performance durability and feel that you can't get from a typical 3D printed prototype. This is crucial for David when specifying components that have to withstand industrial environments. Real-world testing is invaluable.

- Iterate and Refine Designs Quickly: Because the molds are quicker and cheaper to make you can go through several design iterations6 more easily. Test a design find flaws tweak the CAD model and get a new or modified mold quickly. This flexibility is invaluable for perfecting a product before committing to expensive hard tooling. This agility is a competitive edge.

- Bridge to Production: Rapid molds can also serve as "bridge tooling." This means they can produce the first few hundred or thousand parts while your main production mold (if needed) is still being made. This helps you get to market sooner generating revenue while the main tool is prepared.

Honestly it's about reducing risk and accelerating innovation. Rapid mold making is a powerful tool for just that.

What Exactly is a Mold in the Context of Manufacturing?

New to manufacturing terms? Curious about core tools? A mold is a fundamental tool shaping materials into consistent repeatable parts for various products.

A mold in manufacturing is a hollowed-out block or frame. Molten material like plastic or metal is poured or forced into it to create a shaped part.

It might seem basic but understanding what a mold is helps appreciate why rapid molds are so useful. In my early days as a machinist working with molds was a daily affair. A mold at its heart is a custom-made tool designed to shape material. Think of it like a very sophisticated jelly mold but for industrial materials.

Here’s the general idea:

- The Cavity: The mold contains a cavity (or cavities) that is the negative shape of the part you want to create. When I'm designing a mold at Allied Metal creating this cavity with extreme precision is the most critical step. For David's parts which need high accuracy for automation systems this precision is non-negotiable. The quality of the cavity dictates the quality of the part.

- Material Injection/Pouring: Molten plastic liquid silicone rubber or sometimes molten metal is forced or poured into this cavity under pressure. The material fills every detail of the cavity.

- Cooling/Curing: The material inside the mold then cools and solidifies (for plastics and metals) or cures (for some rubbers). Molds often have cooling channels to speed this up. The design of these channels is a science in itself affecting cycle time and part quality!

- Ejection: Once the part is solid the mold opens and the part is ejected. Then the process repeats ready for the next part.

Molds are essential for mass production because they allow you to create many identical parts very efficiently. The complexity of the mold depends on the part – some are simple two-plate designs while others for very intricate parts can have many moving components sliders and lifters. Traditional molds are usually made from hardened steel to withstand millions of cycles. Rapid molds as we've discussed often use other materials like aluminum or even specialized plastics for shorter runs but the fundamental principle of having a shaped cavity remains the same.

How Do Traditional Molds Compare to Rapid Molds?

Weighing tooling options? Unsure which path is best? Understanding the pros and cons of traditional versus rapid molds helps make informed decisions.

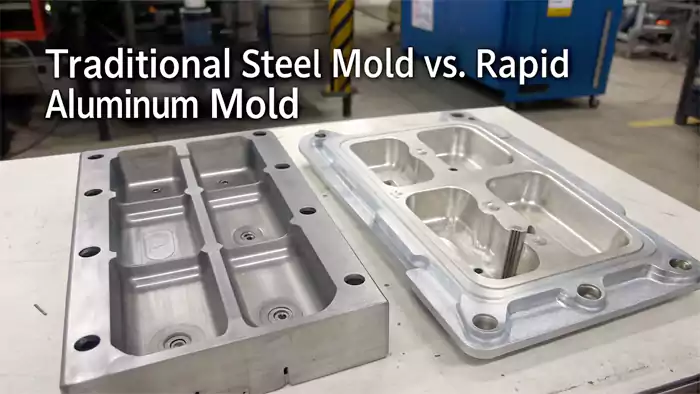

Traditional molds (steel) are for high-volume long-term production. Rapid molds (aluminum 3D printed) are for speed lower volumes and prototyping with lower initial cost.

This is a comparison I discuss often with clients like David. It's not that one is always "better" but they serve different purposes. I started my career working with traditional molds so I know their strengths but rapid molds have opened up so many new possibilities.

Traditional Molds vs. Rapid Molds

| Feature | Traditional Molds (e.g. Hardened Steel) | Rapid Molds (e.g. Aluminum 3D Printed) |

|---|---|---|

| Primary Use | High-volume production (100k+ to millions) | Prototypes low-volume (tens to thousands) |

| Material | Hardened tool steel | Aluminum soft steel plastics |

| Lead Time | Weeks to Months | Days to Weeks |

| Initial Cost | High | Low to Moderate |

| Durability | Very high (millions of cycles) | Lower (hundreds to tens of thousands) |

| Design Changes | Difficult expensive | Easier less costly to modify/remake |

| Ideal For | Mass market products long product life | New product testing quick iterations bridge |

Think of it this way: if David is developing a brand-new component for an automation line and expects to make millions of them over the next 10 years a traditional hardened steel mold is the long-term goal. But for the initial 500 units to validate the design test it in the field and maybe even fulfill early orders a rapid aluminum mold is perfect. It gets him the parts he needs quickly and affordably.

I've seen companies make the mistake of investing heavily in a steel mold too early only to find design flaws later. That's a costly error. Rapid molds help you avoid that. They are about flexibility and speed in the early stages. Sometimes the "rapid mold" is good enough for the entire production life of a niche product if the volumes aren't massive. The choice depends on the project's specific needs.

What Key Factors Should I Consider When Making Prototype Molds?

Planning a prototype run? Want to avoid pitfalls? Key considerations ensure your prototype mold delivers useful parts and valuable insights efficiently.

Consider part quantity material choice complexity required tolerances and your budget. Also think about how quickly you need the prototype parts.

Making prototype molds effectively requires some forethought. As an engineer David you're used to planning and this is no different. Here are the things I always discuss with my clients at Allied Metal before we start:

- How many parts do you really need? Is it 10 for a quick fit check or 500 for field testing? This heavily influences the type of rapid mold. For just a few a 3D printed mold might do. For hundreds aluminum is better. Honesty about quantity saves money.

- What material will the final part be made of? If you need to test with the actual production-intent plastic this will guide mold material choice and design. Some prototype mold materials don't handle all engineering plastics well especially those with high processing temperatures or abrasive fillers. Material choice is critical.

- Part Complexity and Tolerances: How intricate is your design? Does it have undercuts fine details or very tight tolerances? More complex parts might require more sophisticated (and slightly slower or costlier) rapid mold solutions. David's parts for automation often have tight tolerances so we need to ensure the rapid mold can achieve that. We need to be realistic about what's achievable with different rapid methods.

- Budget: While rapid molds are cheaper than production molds there's still a cost spectrum. Be clear about your budget for this prototyping phase. This helps narrow down the options.

- Speed vs. Perfection: How quickly do you need the parts? Sometimes a slightly less durable but faster-to-make mold is acceptable for initial prototypes. For later-stage prototypes you might invest a bit more time for a more robust rapid mold. It's often a trade-off.

- Future Plans: Is this purely a one-off prototype or could it lead to a small production run using the same mold? If it's the latter investing in a slightly more durable rapid mold (like aluminum over a basic 3D print) makes sense. Thinking ahead can save future costs.

I had a client who wanted the cheapest fastest prototype mold. But they also needed 1000 parts in a fairly abrasive plastic. A basic 3D printed mold wouldn't have lasted. We discussed it and they opted for an aluminum mold which was the right call for their needs. It's about balancing all these factors through open communication.

Where is Rapid Tooling Most Commonly Applied?

Exploring manufacturing options? Wondering where rapid tooling shines? Its applications are diverse speeding up development across many industries and product types.

Rapid tooling is widely used for functional prototypes low-volume production bridge tooling (before mass production) and creating custom jigs and fixtures quickly.

Rapid tooling which includes rapid mold manufacturing isn't just a niche technique; it has broad applications. For someone like David in industrial automation it's incredibly relevant. Here’s where I see it used most often at Allied Metal:

- Functional Prototypes: This is a huge one. Engineers need to test if their designs work in the real world with production-intent materials. Rapid molds allow them to get these functional prototypes quickly for testing performance durability and integration with other components. David might use this to test a new sensor housing on a robot. Getting hands-on with a real part is invaluable.

- Low-Volume Production: Not every product needs to be made in the millions. For specialized equipment custom machinery parts or niche market products rapid tooling can often handle the entire production run cost-effectively. I have clients who only ever use aluminum molds because their annual demand is a few thousand parts. It's perfect for these scenarios.

- Bridge Tooling: As mentioned before if you're waiting for a high-volume steel mold to be made (which can take months) a rapid mold can "bridge" the gap by producing the first batch of parts. This gets your product to market faster captures early sales and can even help fund the production tooling.

- Marketing Samples and Test Batches: Before a full launch companies often need a few hundred or thousand units for marketing sales samples or pilot programs. Rapid molds are perfect for this providing market-ready parts quickly.

- Custom Jigs Fixtures and Manufacturing Aids: Beyond end-use parts we also use rapid tooling principles to create custom tools for our own shop or for clients to use in their assembly processes. This speeds up their internal operations and improves consistency.

- Medical Device Prototyping: The medical field uses rapid tooling extensively for developing new devices because they can test with biocompatible materials in smaller controlled batches iterating designs quickly.

Essentially anywhere speed flexibility and lower initial tooling investment are critical for physical parts rapid tooling finds an application. It's about enabling faster innovation cycles and responding quickly to market needs.

How Can I Get Molds Made Quickly for My Project?

Need molds fast? Unsure of the process? Getting quick molds involves clear communication optimized designs and choosing the right manufacturing partner who specializes in speed.

To get quick molds provide clear CAD files discuss your needs (quantity material) and partner with a company specializing in rapid tooling and mold manufacturing.

This is the practical question David would ask. So you need molds quickly – what’s the path? Based on my experience running Allied Metal and helping countless engineers here's my advice:

- Have Your Design Ready (CAD Files): A clear well-defined 3D CAD model (like STEP or IGES files) is the starting point. The more detail you provide (including tolerances material specifications surface finish requirements) the faster a supplier can give you an accurate quote and start working. David's proficiency with CAD is a huge asset here. A good design file is half the battle.

- Clearly Define Your Requirements:

- Quantity: How many parts do you need from this mold? Be specific.

- Material: What plastic or material will be injected? Provide the exact grade if possible.

- Timeline: When do you absolutely need the first parts? A realistic deadline helps.

- Purpose: Is it for form/fit functional testing or a small production run? This context matters.

- Seek Out Specialists in Rapid Tooling: Not every machine shop or mold maker specializes in rapid tooling. Look for companies that explicitly offer it have experience with materials like aluminum for molds and utilize techniques like high-speed CNC and potentially industrial 3D printing for mold components. Ask them about their typical lead times for similar projects and for case studies or examples.

- Request a DFM (Design for Manufacturability) Review: A good rapid tooling partner will review your design and suggest any modifications that could make the mold easier faster or cheaper to produce without compromising function. This proactive step can save a lot of time and prevent issues. I always do this with my clients at Allied Metal.

- Communicate Actively: Stay in touch with your supplier. Quick responses to their questions will keep the project moving. Ensure you understand the process and timelines they propose. Good communication is key to a smooth project.

- Be Realistic: "Quick" is relative. A simple aluminum mold might take a week or two; a more complex one might take three to four. It's still much faster than traditional methods but it's not instantaneous. Managing expectations is key for a good partnership.

When I started Allied Metal my focus was on exactly this – providing fast reliable mold making for engineers who needed to move quickly. Finding a partner who understands the urgency and has the right tools and expertise is the most critical step to getting your molds made quickly and efficiently.

Conclusion

Rapid mold manufacturing offers speed and savings. It helps get your products from design to reality faster bridging the gap to market effectively.

[Footnotes:]

-

Discover how industrial automation systems can streamline processes and boost productivity in manufacturing environments. ↩

-

Discover the significance of prototyping in accelerating your product's journey to market and ensuring its success. ↩

-

Discovering this information can enhance your knowledge on producing specialized parts efficiently. ↩

-

Learn about hardened steel production molds and their critical role in manufacturing processes. This link provides valuable information. ↩

-

Discover strategies to reduce financial risks in design testing, essential for fostering innovation in manufacturing. Check out this resource. ↩

-

Discover the importance of design iterations in refining products and achieving better results. ↩