Editor's Note: Last updated on 2025-10-17 16:00:31 Friday

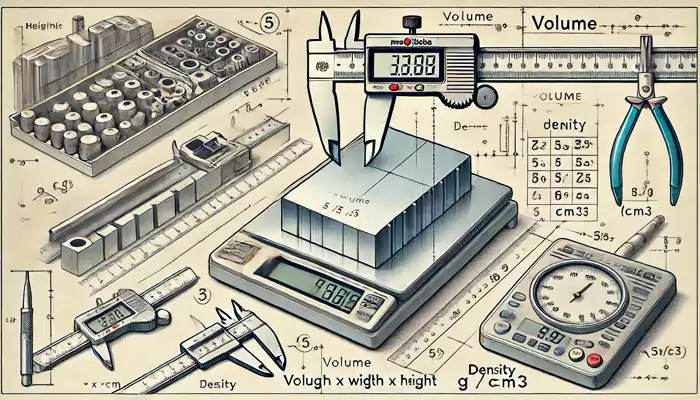

Calculating metal weight accurately can be challenging and time-consuming. I've seen many designers waste hours on manual calculations, often ending up with costly errors.

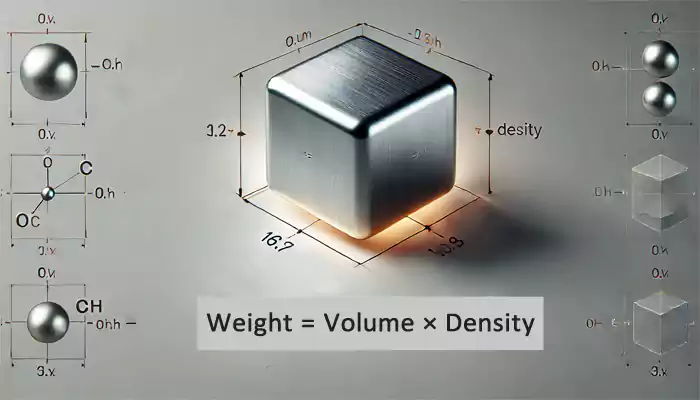

To calculate metal weight, multiply the volume of the metal piece by its density (Weight = Volume × Density). For example, a steel cube with 10cm sides has a volume of 1000cm³, so with steel's density of 7.85 g/cm³, it weighs 7.85kg.

Understanding how to calculate metal weight is crucial for product design, cost estimation, and manufacturing planning. Let me share some practical methods and tools I've learned from my years of experience in the CNC machining industry.

How Do You Calculate the Weight of a Metal?

Many designers struggle with basic metal weight calculations, leading to material waste and budget overruns. I've been there, and I know how frustrating it can be.

Different shapes require different volume calculation formulas. For a rectangular piece, multiply length × width × height. For a cylinder, use π × radius² × height. Then multiply the volume by the metal's density.

Common Metal Densities1

To help you get started, here are the densities of frequently used metals:

| Metal | Density (g/cm³) | Density (lb/in³) |

|---|---|---|

| Steel | 7.85 | 0.284 |

| Aluminum | 2.7 | 0.098 |

| Brass | 8.5 | 0.307 |

| Copper | 8.96 | 0.324 |

| Titanium | 4.51 | 0.163 |

Remember that these are approximate values, as actual densities can vary slightly depending on the specific alloy composition2.

Real-World Application: Machine Base Plate Weight Calculation

Here's a practical example from our shop that shows how weight calculations impact real manufacturing decisions:

We recently quoted a machine base plate for an automotive client. The design engineer specified a 500mm × 800mm × 25mm plate but was concerned about shipping costs and handling requirements.

Part Specifications:

- Material: 304 Stainless Steel (density: 8.0 g/cm³)

- Dimensions: 500mm × 800mm × 25mm

- Features: 12x M12 threaded holes, 4x corner relief cuts

- Surface: Mill finish with deburred edges

Manual Calculation Process:

Our production manager walked through the calculation step-by-step:

-

Calculate Raw Volume:

- 500mm × 800mm × 25mm = 10,000,000 mm³

- Convert to cm³: 10,000,000 ÷ 1000 = 10,000 cm³

-

Account for Material Removal:

- 12x threaded holes: π × (6mm)² × 25mm × 12 = 33,929 mm³ ≈ 34 cm³

- 4x corner reliefs: 25mm × 25mm × 25mm × 4 = 62,500 mm³ ≈ 63 cm³

- Total removed volume: 34 + 63 = 97 cm³

-

Final Weight Calculation:

- Net volume: 10,000 cm³ - 97 cm³ = 9,903 cm³

- Weight: 9,903 cm³ × 8.0 g/cm³ = 79,224 g ≈ 79.2 kg

- In pounds: 79.2 kg × 2.205 = 174.6 lbs

Production Impact:

This calculation revealed several important considerations:

- Shipping: The 174.6 lb weight placed it in a different freight category, affecting cost by 28%

- Handling: Required two-person lift equipment in the workshop

- Material Cost: Raw material represented 65% of the total part cost

- Machining Time: The accurate weight helped estimate fixturing requirements and cycle times

"Getting the weight right upfront saved our client from unexpected freight charges and helped us optimize our machining process. We ended up suggesting a different material that reduced weight by 35% while maintaining performance." - Senior Machinist

What is the Formula for Calculating Weight?

When I first started in manufacturing, incorrect weight calculations cost my company thousands in shipping overcharges. It taught me the importance of getting this right.

The universal formula is Weight = Volume × Density. However, you must ensure all units are consistent. Convert all measurements to the same unit system before calculating.

Unit Conversion Guide3

Here's a practical conversion table I use daily:

| Measurement | Conversion |

|---|---|

| 1 inch | 2.54 centimeters |

| 1 cubic inch | 16.387 cubic centimeters |

| 1 pound | 453.592 grams |

| 1 kilogram | 2.205 pounds |

Common Shape Formulas4

Here are the formulas I use most frequently on the shop floor:

| Shape | Volume Formula | Example |

|---|---|---|

| Rectangular Plate | Length × Width × Height | 10cm × 5cm × 2cm = 100cm³ |

| Cylindrical Bar | π × Radius² × Height | π × (2cm)² × 10cm = 125.66cm³ |

| Round Tube | π × (R_outer² - R_inner²) × Length | π × (3² - 2.5²) × 10cm = 86.35cm³ |

| Hexagonal Bar | (3√3 × Side² ÷ 2) × Length | (3√3 × 2² ÷ 2) × 10cm = 103.92cm³ |

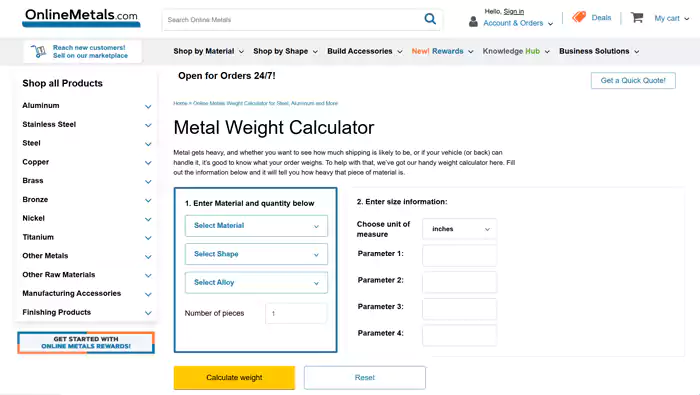

What Online Tools Can Help Calculate Metal Weight?

After countless hours spent on manual calculations, I discovered that online calculators can dramatically speed up the process. I've tested dozens of these tools over the years.

Most online metal calculators require basic inputs like dimensions and metal type, then automatically apply the correct density and formulas to give you the weight instantly.

Top Online Metal Weight Calculators

I regularly use these two calculators that have proven to be the most reliable:

-

- Pros:

- Supports various metals (steel, stainless steel, aluminum, copper).

- Works for rods, tubes, plates, and bars.

- Simple inputs for calculating weight.

- Useful for material purchases and cost estimates.

- Cons:

- Limited to standard shapes.

- Mainly for IMS products.

- Best for: Quick calculations for standard shapes

- Pros:

-

- Pros:

- Supports many metals (steel, aluminum, copper, titanium).

- Works for different shapes (round, square, tube, plate).

- Allows unit conversion (inches, centimeters, meters).

- Calculates weight for both single items and totals.

- Good for estimating shipping costs.

- Cons:

- Limited to OnlineMetals' products.

- No options for custom shapes.

- Best for: Complex projects requiring detailed documentation

- Pros:

Here's a quick comparison of these tools:

| Feature | IMS Calculator | OnlineMetals Calculator |

|---|---|---|

| Basic Shapes | ✓ | ✓ |

| Complex Shapes | × | ✓ |

| Cost Calculator | × | ✓ |

| Mobile Friendly | ✓ | ✓ |

| Registration Required | No | Yes (for advanced features) |

| Export Results | No | Yes |

Need precise weight calculations for your project? Contact our engineering team for expert material selection and weight optimization tailored to your specific application.

Pro Tips from the Shop Floor

After 15 years of machining, here are the weight calculation insights I wish I'd known earlier:

1. Always Add 8-12% for Machining Allowance

When ordering raw material, calculate the finished part weight, then add extra for:

- Fixturing tabs and mounting blocks

- Roughing cuts and finishing passes

- Potential material defects or inclusions

2. Density Variations Matter

The "standard" densities are averages. For critical applications:

- 6061 Aluminum can vary from 2.69-2.71 g/cm³

- 304 Stainless Steel ranges from 7.90-8.03 g/cm³

- These small differences can add up on large orders

3. Calculate Weight Early in Design

I've seen designs that were perfect on paper but impossible to handle in reality. Consider:

- Can your equipment lift the finished part?

- Will the weight affect assembly or installation?

- Are there weight restrictions for shipping or end use?

4. Verify with Multiple Methods

For important projects, I always:

- Calculate manually as a baseline

- Use at least two different online calculators

- Compare against similar parts we've made before

Conclusion

Calculating metal weight comes down to knowing the volume and density of your material. Whether you use manual calculations or online tools, double-check your results to avoid costly mistakes.

Footnotes:

-

Understanding metal densities is crucial for material selection in engineering and manufacturing. ↩

-

Exploring this topic can provide insights into material properties and their practical implications. ↩

-

Explore this resource for a detailed understanding of unit conversions, essential for accurate measurements. ↩

-

This link will provide you with essential formulas for calculating volumes, crucial for various applications. ↩