Surface Roughness: The Machinist's Guide to Getting Finishes Right

- November 28, 2024

- Tony

- Last updated on October 29, 2025 by Lucy

When “Smooth Enough” Isn’t Good Enough

After 25 years in the machining business, I can tell you this: surface finish is where good parts become great parts. I’ve seen beautifully designed components fail because someone didn’t understand surface roughness. Let me break down what actually matters in terms you can use on the shop floor tomorrow.

1. overview

What is surface roughness?

Surface roughness refers to the surface of the part machining has a smaller pitch and tiny peaks and valleys of the unevenness of the tiny irregularities, which mainly reflects the surface morphology of the details of the characteristics.

Surface Roughness vs Finish: What's the Real Difference?

Here’s how I explain it to new engineers:

- Surface Roughness: Measurable numbers from your profilometer

- Surface Finish: What your customer sees and feels

The roughness numbers don’t lie, but the finish is what sells your product.

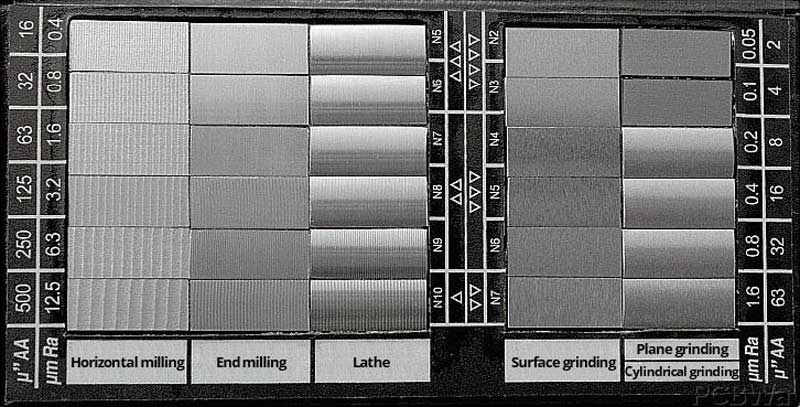

Surface Roughness vs. Finish Grade Comparison

Roughness Parameter (Ra) | Surface Finish Grade | Surface Features | Processing Methods |

Ra 0.012 - 0.025 | 14 | Mirror-like Gloss | Superfine grinding, polishing, super finishing, mirror finish |

Ra 0.025 - 0.05 | 13 | High Gloss | Fine grinding, polishing, super finishing |

Ra 0.05 - 0.1 | 12 | Glossy Surface | Precision turning, precision grinding, fine surface grinding |

Ra 0.1 - 0.2 | 11 | Matte Mirror | Grinding, precision turning with diamond tools, precision grinding |

Ra 0.2 - 0.4 | 10 | Slightly Visible Marks | Grinding, polishing, cold drawing |

Ra 0.4 - 0.8 | 9 | Visible Marks | Grinding, polishing, cold drawing |

Ra 0.8 - 1.6 | 8 | Noticeable Tool Marks | Rough grinding, rough turning, rough milling, rough planing |

Ra 1.6 - 3.2 | 7 | Visible Machining Marks | Rough turning, rough milling, rough planing, drilling |

Ra 3.2 - 6.3 | 6 | Slightly Visible Machining Marks | Rough turning, rough milling, rough planing |

Ra 6.3 - 12.5 | 5 | Distinct Machining Marks | Rough turning, rough milling, rough planing |

Ra 12.5 - 25 | 4 | Noticeable Tool Marks | Turning, boring, planing |

Ra 25 - 50 | 3 | Distinct Machining Marks | Turning, boring, planing |

Ra 50 - 100 | 2 | Rough Surface | Rough turning, rough milling, rough planing |

Ra > 100 | 1 | Extremely Rough Surface | Rough machining, casting, forging |

- Ra Value (Average Surface Roughness): It measures the average height variation of the surface; a lower Ra value indicates a smoother surface and a higher finish quality.

- Finish Grade: Ranges from 1 to 14, indicating surface smoothness. Grade 1 is very rough, and grade 14 is a mirror-like finish.

- Processing Methods: Different techniques are used based on the Ra value to achieve the desired surface finish.

Case Study: The $50,000 Hydraulic Cylinder Lesson

We had a client manufacturing hydraulic cylinders for construction equipment. Their seals were failing every 200 hours instead of the required 2000 hours.

The Problem:

- Seal surface specified as Ra 0.8μm

- Actual measurement showed Ra 0.8μm but Rz of 6.3μm

- Deep microscopic grooves were cutting the seals

- Field failure rate: 35%

- Warranty costs: $50,000 monthly

The Investigation: We put the cylinder rods under our digital microscope and found:

- Random deep scratches from improper handling

- Inconsistent grinding patterns

- Peak heights varying by 400%

Our Solution:

- Changed from grinding to hard turning with CBN inserts

- Implemented 100% Rz measurement in addition to Ra

- Added protective packaging immediately after machining

- Trained operators on proper handling procedures

The Results:

- Ra maintained at 0.8μm, Rz reduced to 1.6μm

- Seal life increased to 2500+ hours

- Warranty claims dropped by 92%

- Customer satisfaction: 100% for 18 months running

2. Surface roughness measurement methods

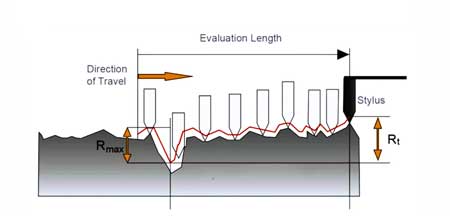

Contact Profilometers - The Shop Floor Workhorse

These are the units you see crawling across parts. They’re accurate but slow, and you can’t use them on soft materials.

When to use them:

- Final inspection of critical components

- Customer disputes about finish quality

- Process validation

Laser Scanners - For the Fancy Stuff

These give you 3D color maps of your surface. Perfect for R&D but overkill for production.

3. Factors affecting surface roughness

Main influencing factors: type of material to be machined, machining process, tool condition and machining speed.

Material Matters More Than You Think

Tool Condition Is Everything

A dull tool doesn’t cut – it tears. I can hear the difference from across the shop.

Speeds and Feeds - The Magic Combination

For 6061 aluminum:

- Finishing: 2400 RPM, 8 IPM, 0.010″ DOC

- Tool: 3-flute carbide end mill

- Result: 0.4μm Ra consistently

For example, high hardness materials usually require the use of higher precision CNC machining tools to obtain lower roughness values. Also, machining speeds that are too fast may result in uneven surfaces, which can affect part performance.

4. Surface roughness requirements in manufacturing

In automotive manufacturing, surface smoothness is crucial for performance and safety. Engine parts, transmission systems, and brakes require smooth surfaces to reduce friction and wear, ensuring long-term reliability. Excessive roughness can lead to faster wear and decreased fuel efficiency.

The aerospace industry demands tighter surface roughness standards, especially for aircraft parts and engine components. Smooth, high-precision surfaces reduce drag, improve fuel efficiency, and enhance safety and durability. Even minor surface defects can lead to material fatigue and jeopardize flight safety.

3. Mechanical Parts

For mechanical equipment like gears and bearings, smoother surfaces reduce friction and wear, extending component lifespan and improving efficiency. Precision parts often require highly smooth surfaces to minimize energy loss and heat buildup.

4. Precision Instruments

Parts for precision instruments and electronics, such as optics, sensors, and microprocessors, require extremely smooth surfaces for accurate measurements and stable performance. Even small surface irregularities can cause performance issues and affect measurement accuracy.

5. Surface roughness symbols and abbreviations

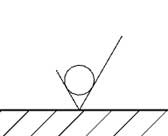

Standard surface finish symbol, applicable to surfaces produced by any method.

The horizontal bar shows machining is needed, with extra material added.

Indicates the surface must be formed by processes like casting or forging, with no material removal.

a – average roughness value (Ra);

b – production method, coating, note, or other additional information;

c – roughness sampling length in millimeters or inches;

d – direction of the surface lay;

e – minimum material removal requirement in millimeters;

f – alternate surface finish parameter.

Common Codes:

- Ra = average roughness

- Rz = ten-point height roughness

- Ry = maximum height roughness

- RMS = Root Mean Square

- CLA = Centerline Average Roughness

- Rt = Total height roughness

- N = Grade value

6. Summary

Texture and quality of the product surface are vital for both aesthetics and product performance, affecting factors like corrosion resistance, adhesion, conductivity, and abrasion resistance. Understanding these aspects leads to better design and improved functionality.