High-temperature parts rarely fail during design reviews. They fail after production, when distortion, wear, or oxidation appears under real operating conditions.

For CNC machining, the best heat-resistant metal is the one that survives operating temperature, can be machined with control, and fits cost and lead-time expectations—not the one with the highest theoretical limit.

Over the years, I have seen procurement teams focus on temperature numbers alone. The result is often excessive cost, long lead times, or parts that are difficult to machine consistently. The sections below reflect how I help buyers and engineers choose materials that work in real production.

How Heat Resistance Is Evaluated in CNC Machining?

Many material discussions start with melting point. In CNC machining, that approach is incomplete.

Heat resistance for CNC parts is defined by continuous service temperature, strength retention, oxidation behavior, and machining stability under cutting heat.

A material that survives extreme heat but causes tool failure or dimensional drift during machining introduces risk instead of reliability.

Melting Point vs Continuous Operation

Most components fail far below melting temperature. Creep, softening, and oxidation define real limits. Continuous operating temperature1 is the first value I evaluate.

Machining-Induced Heat2

CNC cutting generates concentrated heat. Materials with low thermal conductivity trap heat at the tool edge, accelerating wear and risking surface damage.

Long-Term Stability

For furnaces, turbines, and energy systems, the ability to hold shape and strength over time matters more than short-term heat spikes.

Top 5 Heat-Resistant Metals Used in CNC Machining

These five metals appear repeatedly in successful high-temperature CNC projects because they balance performance, machinability, and procurement reality.

Each material below includes clear guidance on when it is the right choice, when it is not, and what to expect during CNC machining.

This structure allows procurement managers to quickly narrow options while understanding machining implications early.

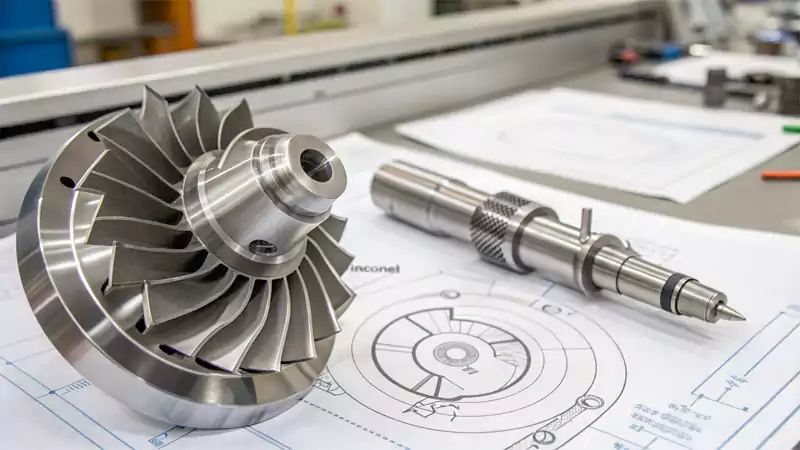

1. Inconel (Nickel-Based Superalloy)

Inconel is the default choice for extreme operating temperatures between 800°C and 1100°C.

From a purchasing perspective, Inconel is suitable when failure cost is far higher than machining cost. Typical parts include turbine housings, exhaust components, and high-temperature energy equipment.

From a CNC machining standpoint, Inconel work-hardens rapidly and resists cutting. Heat concentrates at the tool edge, which shortens tool life. Machining requires rigid machines, conservative cutting speeds, and experienced programming. Cycle times are long, and tooling cost is high.

Best for:

- Long-term high-temperature exposure

- Safety-critical or mission-critical parts

- Small to medium batch sizes

Not ideal for:

- Cost-driven designs

- Short-term heat exposure

2. Titanium Alloy (Ti-6Al-4V)3

Titanium alloy is often chosen when weight, strength, and moderate heat resistance must be balanced.

It performs reliably up to about 600°C and offers excellent strength-to-weight ratio. For procurement teams, titanium often replaces Inconel when extreme temperature is not required but performance still matters.

In CNC machining, titanium has low thermal conductivity. Heat remains near the cutting zone, which can cause tool wear if speeds are too high. However, with proper feeds, sharp tools, and stable setups, titanium machining is predictable and repeatable.

Best for:

- Lightweight high-temperature components

- Aerospace, robotics, and advanced industrial systems

- Complex geometries requiring precision

Machining notes:

- Control cutting heat

- Avoid aggressive speeds

- Expect moderate tooling cost

3. High-Temperature Stainless Steel (310, 321)

High-temperature stainless steels are the most procurement-friendly option on this list.

They offer good oxidation resistance up to roughly 900–1000°C while remaining cost-effective and widely available. For many industrial heaters, frames, and exhaust structures, these grades meet requirements without unnecessary expense.

From a CNC perspective, machining behavior is familiar. Tool wear4 is manageable, tolerances are stable, and production scaling is straightforward. This predictability makes stainless steel attractive for medium to large production volumes.

Best for:

- Industrial equipment

- Medium to large batch production

- Cost-sensitive projects with moderate heat exposure

Why buyers choose it:

- Stable supply chain

- Shorter lead times

- Lower machining risk

4. Molybdenum

Molybdenum5 enters the discussion when operating temperatures exceed the comfort zone of steels and titanium.

With a melting point above 2600°C, it maintains strength in very high-temperature and vacuum environments. Procurement teams usually encounter molybdenum in furnace components or thermal shielding.

CNC machining molybdenum requires caution. The material is brittle and sensitive to stress. Clamping must be even, and designs should avoid sharp corners. Simple geometries are preferred, and batch sizes are usually small.

Best for:

- Furnace internals

- Vacuum and controlled-atmosphere systems

- Low-volume, high-value parts

Design trade-off:

- Geometry may need simplification to ensure machinability

5. Tungsten

Tungsten6 is selected only when temperature requirements exceed all other metallic options.

With a melting point above 3000°C, it is unmatched in heat resistance. However, from a CNC machining perspective, tungsten is extremely difficult to cut. Tool wear is severe, feed rates are low, and machining costs rise quickly.

Procurement teams typically see tungsten used in specialized heat sources, radiation shielding, or extreme furnace applications. Designs often minimize machined features to control cost.

Best for:

- Extreme temperature environments

- Functional components with simple geometry

Important reminder:

- Tungsten is a last-resort material, not a standard choice

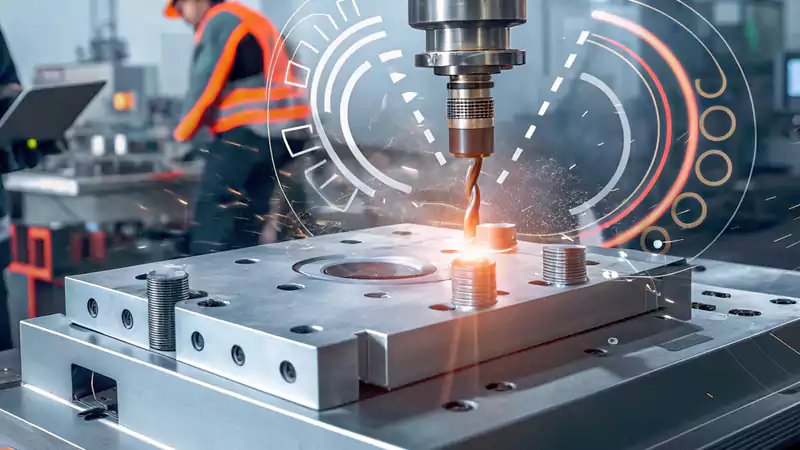

CNC Machining Considerations for Heat-Resistant Metals

Choosing a heat-resistant metal also commits the project to specific machining realities.

High-temperature materials increase machining complexity, tooling cost, and cycle time, all of which must be planned early.

Tooling and Process Control

Rigid machines, optimized tool paths, and controlled cutting parameters are essential. Experience matters more than raw machine power.

Cost and Lead Time Impact

Hard-to-machine metals extend production schedules. Procurement timelines should reflect this from the quoting stage.

Tolerance Expectations

Tight tolerances are achievable, but only when design intent aligns with material behavior.

How to Choose the Right Heat-Resistant Metal for Your Application?

Material selection should begin with operating reality, not extreme specifications.

The right choice balances temperature, load, machinability, budget, and supplier capability.

I guide most teams using these priorities.

Operating Temperature First

Define continuous operating temperature. Avoid selecting materials based on peak or theoretical limits.

Load and Environment

Account for stress, vibration, oxidation, and exposure duration.

Batch Size and Budget

High-performance alloys suit low-volume critical parts. Stainless steel often wins for production.

CNC Supplier Experience

Choose partners with proven machining history in the selected material.

Case Study: Selecting Inconel for a High-Temperature Energy Component

A customer faced repeated deformation in a gas flow component near a turbine outlet.

After reviewing temperature exposure and machining feasibility, we replaced stainless steel with Inconel to stabilize performance.

Key Parameters

| Parameter | Before | After |

|---|---|---|

| Operating Temperature | 850°C | 950°C |

| Material | Stainless Steel 310 | Inconel 718 |

| Tolerance | ±0.02 mm | ±0.02 mm |

| Batch Size | 120 pcs | 120 pcs |

| Machining Time | 45 min/part | 95 min/part |

| Tool Life | 18 pcs/tool | 6 pcs/tool |

Although machining cost increased, part life more than tripled. Field failures stopped, and the material decision paid for itself quickly.

Conclusion

For CNC machining, heat resistance is a system decision. The best metal delivers stable performance, predictable machining, and controlled cost over the full life of the part.

-

Understanding continuous operating temperature is crucial for selecting materials that ensure reliability in high-heat applications. ↩

-

Exploring machining-induced heat can help you grasp its impact on tool wear and material integrity during manufacturing processes. ↩

-

Learn about the advantages of Titanium Alloy in aerospace and industrial applications. ↩

-

Explore the causes of tool wear and how to mitigate it during machining processes. ↩

-

Find out how molybdenum performs in extreme environments and its industrial applications. ↩

-

Understand the unique properties of tungsten and its role in high-temperature environments. ↩