EDITOR'S NOTE: Updated on October 16, 2025. We've added a detailed case study showing how a functional prototype solved critical design challenges for an automotive component.

Launching a new product without testing its core functions is a huge gamble. Flaws discovered late mean costly redesigns, delays, and potential market failure.

A functional prototype is a working model built to test and validate a product's core functions and user interactions, rather than its final appearance. It proves the concept actually works.

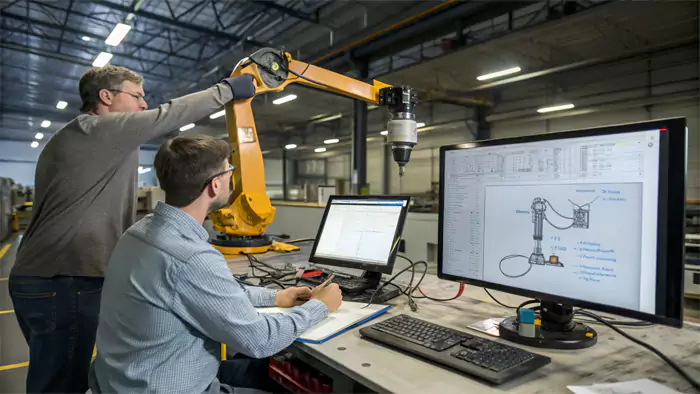

In my years at Allied Metal, helping engineers like David bring complex designs to life through CNC machining and 3D printing, I've seen the immense value of good prototyping. There are different kinds of prototypes, but when you really need to know if your idea will work, that's where a functional prototype shines. My insight is that a functional prototype is the best way to bring an idea to life and actually see how it performs in the real world. It’s not about making it look pretty for a tradeshow, though that has its place too. No, it’s not just about looks—it’s about making sure the concept actually works before going all in on expensive tooling and full-scale production. Getting this stage right can save an incredible amount of time, money, and frustration down the line.

What Exactly Do We Mean by a 'Functional Prototype'?

You hear engineers talk about "functional prototypes," but what does this term truly represent? How does it differ from just any early model or mock-up of a product?

A functional prototype is a working model designed primarily to simulate and test the core functionality of a product, demonstrating how it works rather than how it will finally look.

Diving Deeper into the Definition of a Functional Prototype

When we talk about a "functional prototype," we're referring to a specific type of early model created during the product development process. Its primary purpose, as the name suggests, is to demonstrate and test the product's core functions1. This means it's built to operate and behave, at least in key aspects, like the intended final product.

Unlike other types of prototypes that might focus on aesthetics, ergonomics, or simply conveying an idea (like a visual mock-up), a functional prototype is all about performance. As my insight highlights, it’s about making sure the concept actually works. For an engineer like David developing complex industrial automation systems, this could mean building a prototype that:

- Moves in the intended way.

- Processes signals correctly.

- Handles loads as designed.

- Allows users to interact with its key features.

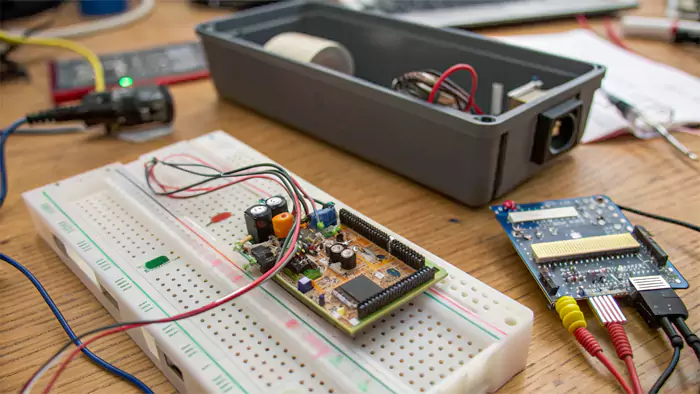

It might not be made from the final production materials, and it often won't have the polished look of the finished product. It might even look quite rough, perhaps with some off-the-shelf components and visible wiring or mechanics. However, if it successfully performs the essential tasks it's designed for, it has served its purpose. This early validation of function2 is incredibly valuable for identifying design flaws, testing assumptions, and gaining confidence in the technical feasibility of a concept before committing to more expensive development stages. It’s about proving the "works-like" aspect, not necessarily the "looks-like" or "feels-like" aspects.

Functional vs. Non-Functional Prototypes: What's the Core Difference?

Products go through various prototype stages. How does a functional prototype stand apart from a non-functional one, and when would you use each type?

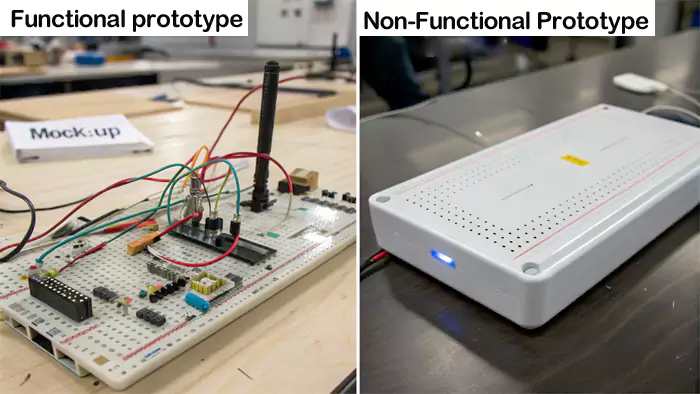

Functional prototypes test how a product works, focusing on its core operations. Non-functional prototypes (e.g., visual mock-ups) focus on look and feel, like aesthetics and ergonomics.

Diving Deeper into the Distinction

Understanding the difference between functional and non-functional prototypes is key for an engineer like David to plan an effective product development strategy. Both types serve important, but distinct, purposes.

Functional Prototypes (Often called "Works-Like" Prototypes):

- Primary Goal: To simulate and test the core functions and operational aspects of the product. My insight that "it’s about making sure the concept actually works" perfectly describes this.

- Focus: Performance, user interaction with features, technical feasibility, system integration (how different parts work together).

- Appearance: Aesthetics are secondary. They might be made from different materials than the final product (e.g., 3D printed plastic instead of machined metal if the function can still be tested) and may look unpolished.

- Use Cases: Validating engineering designs, testing algorithms, proving a technical concept, identifying operational flaws, conducting user testing on core features. For example, a prototype of a new robotic gripper that can actually pick up objects.

- Our Services: At Allied Metal, we help create functional prototypes using CNC machining for robust parts or 3D printing for complex geometries or quick iterations.

Non-Functional Prototypes (Often "Looks-Like" or "Feels-Like" Prototypes):

- Primary Goal: To represent the appearance, form, size, shape, and sometimes the feel (ergonomics) of the final product.

- Focus: Aesthetics, user experience related to form, physical dimensions, visual appeal, material finish (sometimes simulated).

- Functionality: They typically do not perform the core functions of the final product. They might be static models.

- Use Cases: Gaining feedback on design aesthetics, testing ergonomics, creating models for marketing or photoshoots, validating overall size and shape in an assembly. For example, a clay model of a car, a 3D printed casing for an electronic device (without the electronics), or a foam model of a handheld tool.

| Feature | Functional Prototype | Non-Functional Prototype |

|---|---|---|

| Main Focus | How it WORKS | How it LOOKS & FEELS |

| Operations | Performs core functions3 | Usually static, no core functions |

| Materials | Can vary, chosen for function | Can vary, chosen for appearance/feel |

| Aesthetics | Secondary, often unpolished | Primary, aims for visual accuracy |

| Purpose | Test function, prove concept works | Test look, feel, ergonomics, visuals |

Both types are valuable. Often, a project might involve developing both in parallel or sequentially to cover all aspects of the design.

Beyond Functional: What Are the Main Types of Prototypes Engineers Use?

"Prototype" is a broad term. Beyond just functional, what other common types exist, and how do they fit into the overall product development journey for engineers?

Prototypes range from low-fidelity (sketches, paper models) to medium-fidelity (wireframes, basic physical mock-ups) and high-fidelity (functional prototypes, looks-like/works-like models closely resembling the final product).

Diving Deeper into Prototype Classifications

While we're focusing on functional prototypes, it's helpful for engineers like David to understand the broader landscape of prototyping. Prototypes can be categorized in many ways, but a common approach is by their fidelity – how closely they resemble the final product in terms of look, feel, and function.

1. Low-Fidelity Prototypes:

- Description: These are quick, simple, and inexpensive ways to explore initial ideas and concepts. They are not meant to be detailed or functional in a technical sense.

- Examples:

- Sketches and Diagrams: Hand-drawn or digitally created visuals to illustrate concepts.

- Paper Prototypes: Using paper cutouts to simulate user interfaces or physical interactions.

- Storyboards: A sequence of drawings or images showing how a user might interact with a product or system.

- Cardboard Mock-ups: Simple physical representations of form and size.

- Purpose: Early concept exploration, brainstorming, quick feedback, testing basic flow and layout.

2. Medium-Fidelity Prototypes:

- Description: These offer more detail and interaction than low-fidelity ones but are still not fully polished or completely functional. They provide a better sense of the product's structure and basic interactions.

- Examples:

- Wireframes (for software/interfaces): Basic screen blueprints showing layout and navigation.

- Interactive Mock-ups: Clickable prototypes for software, or simple physical models with some moving parts made from easily workable materials (e.g., foam core, basic 3D prints).

- Basic Physical Models: More refined than cardboard, perhaps showing key components but not full functionality.

- Purpose: Testing information architecture, basic usability, workflow, and refining core interactions. A very early, simplified functional prototype might fall into this category.

3. High-Fidelity Prototypes:

- Description: These are the most detailed and realistic prototypes, closely resembling the final product in appearance, interaction, and/or function.

- Examples:

- Functional Prototypes (Works-Like): As we've discussed, these focus on demonstrating core functionality. This is where my insight about it being "the best way to bring an idea to life and actually see how it performs" truly applies.

- Appearance Prototypes (Looks-Like): High-quality visual models that mimic the final product's aesthetics, materials, and finish.

- Looks-Like/Works-Like Prototypes: The most comprehensive type, aiming to be very close to the final product in both appearance and function. These are often used for final validation before production.

- Purpose: Detailed usability testing, final design validation, technical testing, demonstrating to stakeholders, pre-production checks.

Functional prototypes typically fall into the medium to high-fidelity range, depending on how many functions they simulate and how refined they are. Our CNC machining and 3D printing services at Allied Metal are often used to create these more advanced, high-fidelity prototypes.

How Do You Go About Creating a Functional Prototype?

You understand what a functional prototype is. But what are the practical steps involved in actually building one to test your product's core operations effectively?

Define core functions, select appropriate materials and manufacturing methods (like 3D printing or CNC machining), develop the CAD design, fabricate/assemble, and then rigorously test and iterate.

Diving Deeper into the Creation Process

Creating a useful functional prototype involves a structured approach4. It’s not just about quickly cobbling something together; it's about strategically building a model that can provide meaningful answers about your design's viability. Here’s a general process an engineer like David might follow, and where Allied Metal's services can assist:

-

Define Scope and Core Functions:

- Clearly identify which specific functions of the product need to be tested with this prototype. You don't always need to prototype every function. Focus on the riskiest assumptions or the most critical operations. My insight about ensuring "the concept actually works" applies here—what defines "works"?

- Set clear success criteria: What does the prototype need to do to be considered successful?

-

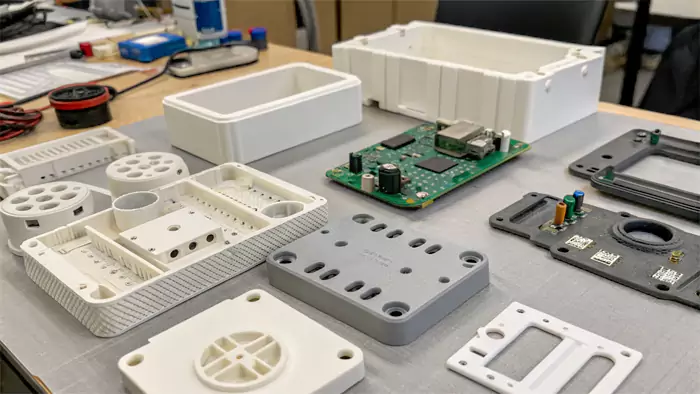

Select Materials and Components:

- Choose materials that allow the prototype to perform the intended functions. These might not be the final production materials. For example, you might use 3D printed plastics for a part that will eventually be metal if the plastic version can adequately test the mechanism or fit.

- Identify any off-the-shelf components (motors, sensors, fasteners) that can be incorporated to save time and cost.

-

Design the Prototype (CAD):

- Develop a 3D CAD model of the prototype. This design should focus on achieving the core functionalities. Simplify non-essential features to save time and resources.

- Consider the manufacturing method you'll use (see next step) during the design phase. For example, design for 3D printing differently than for CNC machining.

-

Choose Manufacturing Method(s) and Fabricate:

- 3D Printing: Excellent for complex geometries, quick iterations, and creating custom enclosures or internal components. We use various 3D printing technologies at Allied Metal for this.

- CNC Machining: Ideal for parts requiring higher strength, tighter tolerances, or specific material properties that 3D printed plastics can't offer. We can machine parts from engineering plastics or metals.

- Off-the-Shelf Parts & Electronics: Integrate standard components. If electronics are involved, this might mean using development boards like Arduino or Raspberry Pi for early functional prototypes.

- Assembly: Put all the pieces together.

-

Test, Evaluate, and Iterate:

- Rigorously test the prototype against the defined functions and success criteria. Does it work as expected?

- Identify any failures, weaknesses, or areas for improvement. This is where the real learning happens.

- Based on the test results, iterate on the design and create improved versions of the prototype until the core functions are validated.

This iterative process of design, build, and test is fundamental to effective functional prototyping.

Case Study: Functional Prototype for Automotive Transmission Sensor Mount

Wondering how functional prototyping works in real-world manufacturing? This case from our shop floor shows how a working prototype caught critical design flaws that CAD models alone would have missed.

We delivered a functional prototype that identified three major design flaws in an automotive transmission sensor mount, saving the client an estimated $85,000 in tooling modifications and preventing a 12-week production delay.

A major automotive supplier came to us with a challenging requirement: validate the design of a new transmission-mounted sensor bracket before committing to $150,000 in production tooling. The part had to survive harsh under-hood conditions while maintaining precise alignment.

Part Specifications & Requirements:

- Material: 6061-T6 Aluminum (production intent)

- Operating Environment: -40°C to 125°C, vibration to 15g RMS

- Critical Tolerance: Sensor bore position ±0.05mm

- Load Requirements: Withstand 50N static load, 25N cyclic vibration

- Mounting: Three M8 threaded inserts with helicoil reinforcement

Prototyping Approach & Technical Details:

We took a multi-material approach to balance cost and functionality:

| Component | Manufacturing Method | Material | Key Features |

|---|---|---|---|

| Main Bracket | CNC Machining | 6061-T6 Aluminum | Production-intent material for accurate testing |

| Sensor Housing | SLA 3D Printing | High-temp resin | Complex internal channels, transparent for inspection |

| Mounting Inserts | Press-fit stainless steel | 304 SS | Actual helicoil inserts for load testing |

| Test Fixture | CNC Machined | Steel plate | Simulates transmission housing interface |

Testing Protocol & Discovered Issues:

-

Thermal Cycling Test (-40°C to 125°C, 500 cycles):

- Issue Found: Differential expansion caused 0.12mm sensor misalignment at temperature extremes

- Solution: Added expansion slots and changed fastener pattern

-

Vibration Testing (10-2000 Hz, 15g RMS):

- Issue Found: Resonant frequency at 320Hz caused mounting bolt loosening

- Solution: Added localized ribbing to shift resonance to 450Hz

-

Static Load Testing (50N applied at sensor tip):

- Issue Found: Deflection exceeded 0.8mm specification (measured 1.2mm)

- Solution: Increased wall thickness from 3mm to 4.5mm in critical areas

Key Performance Data:

- Prototype Cost: $4,200 (including all testing fixtures)

- Development Time: 3 weeks from CAD to final test report

- Design Iterations: 3 physical revisions based on test findings

- Tooling Modifications Avoided: 7 major changes identified through prototyping

- Estimated Savings: $85,000 in avoided tooling rework + $220,000 in potential warranty claims

The production manager later told us: "That functional prototype paid for itself twenty times over. Finding those resonance and thermal expansion issues before steel was cut saved our project timeline and probably saved the program. We learned things in three weeks of prototyping that months of simulation hadn't revealed."

This case demonstrates why we always recommend functional prototyping for complex mechanical components—sometimes the real world has surprises that even the best CAD models can't predict.

Ready to Build a Functional Prototype That Uncovers Hidden Flaws?

As this case study shows, a well-executed functional prototype isn't an expense—it's one of the most valuable investments you can make in your product's success. It moves the conversation from "Will it work?" to "Here's exactly how it works, and here's the data to prove it."

At Allied Metal, we don't just manufacture parts; we partner with engineers to de-risk development. Our expertise in CNC machining, 3D printing, and precision assembly allows us to build functional prototypes that truly test the limits of your design under real-world conditions.

Have a challenging component that needs validation? Let's build a prototype that gives you the confidence to move forward.

What Key Benefits Does Functional Prototyping Offer Your Project?

Investing time and resources into building a working model seems logical. But what specific, tangible advantages does creating a functional prototype bring to the product development cycle?

Functional prototyping validates core operations early, reduces risks by spotting flaws before tooling, improves designs through real-world testing, enhances stakeholder communication, and can accelerate time-to-market.

Diving Deeper into the Advantages

Creating functional prototypes offers a multitude of benefits that can significantly impact the success of a product development project. For an engineer like David, these advantages translate into reduced risks, better products, and more efficient use of resources. My insight that it's the "best way to bring an idea to life and actually see how it performs in the real world" underscores these benefits.

-

Early Validation of Core Functionality:

- This is the primary benefit. You get to see if your concept actually works as intended, performing its key tasks in a tangible way. This early feedback is invaluable for confirming technical feasibility.

-

Risk Reduction:

- By identifying design flaws, engineering problems, or incorrect assumptions early on through a functional prototype, you can address them before investing in expensive production tooling or committing to large-scale manufacturing. This significantly reduces financial and technical risks.

-

Improved Design and Iteration:

- Testing a functional prototype often reveals unexpected issues or areas for improvement that weren't apparent from CAD models alone. It allows for data-driven design changes and rapid iteration, leading to a more robust and user-friendly final product.

-

Enhanced Communication and Stakeholder Buy-in:

- A working model is a powerful communication tool. It makes it much easier to demonstrate the product's value and functionality to team members, management, investors, or potential customers. Seeing is believing.

-

User Testing and Feedback:

- Functional prototypes can be put in the hands of actual users to gather feedback on usability and performance. This early user input can guide design refinements and ensure the product meets real-world needs.

-

Refinement of Technical Specifications:

- Testing a functional prototype can help refine technical specifications, such as power requirements, material strength needed, or component tolerances, based on observed performance.

-

Faster Time-to-Market:

- By resolving critical functional issues early in the development cycle, you can avoid major setbacks and delays later on, ultimately leading to a faster path to market.

-

Cost Savings:

- While there's an upfront cost to creating functional prototypes, the savings from catching errors early, avoiding costly rework, and preventing product failures far outweigh this initial investment.

In essence, functional prototyping is a critical de-risking and learning activity that builds confidence and paves the way for a more successful product launch.

Conclusion

Functional prototypes are vital for testing core product operations early. They reduce risk, refine designs, and ensure your concept truly works before major investment.

-

Exploring this resource will provide insights into effective methods for validating your prototype's functionality, ensuring it meets design expectations. ↩

-

Understanding early validation of function can help you grasp its importance in identifying design flaws and testing assumptions before full production. ↩

-

Learning about core functions can enhance your knowledge of essential design elements that drive product success. ↩

-

A structured approach ensures systematic progress in engineering projects. Discover more about its benefits and applications in this informative resource. ↩

The 68jlloginapp is super convenient! Makes playing on the go so much easier. Definitely worth downloading! Get it here: 68jlloginapp