CNC machines often fail not because of cutting paths, but because auxiliary actions are misunderstood. I have seen good parts ruined by small command mistakes that people overlook.

M-code is the command language that controls non-cutting actions in CNC machines, such as spindle start, coolant flow, and tool change. Understanding it is essential for stable, repeatable, and safe machining operations.

I have worked with CNC machines for more than twenty years. In that time, I learned that most production problems do not come from geometry, but from how the machine is told to behave. That is where M-code quietly controls everything in the background.

What Is M-Code and How Does It Function in CNC Machines?

M-code problems often appear late in production. When they show up, they cost time, scrap, and trust. Many engineers know G-code well but treat M-code as an afterthought.

M-code is a set of commands that control machine functions rather than tool movement, working together with G-code to execute a complete machining cycle.

What M-code controls in real machining

M-codes manage actions that do not directly remove material. These actions still decide whether a part is produced safely and consistently.

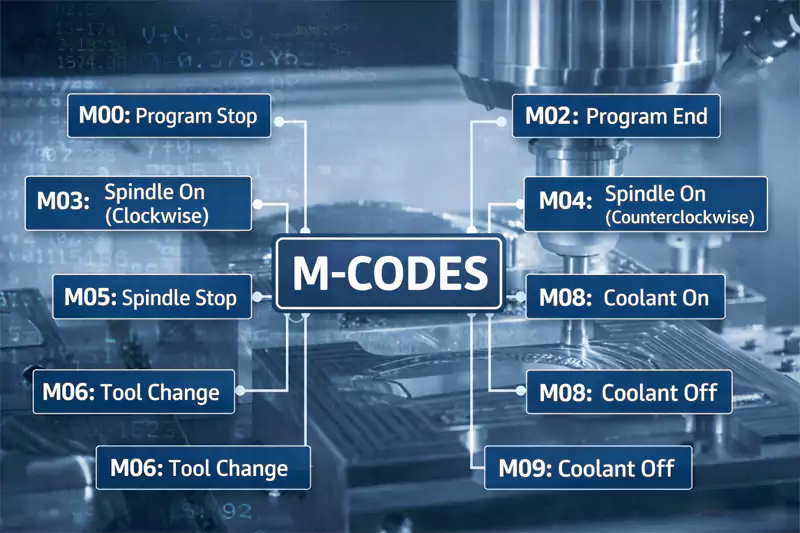

Typical functions include:

- Spindle start and stop

- Coolant on and off

- Tool change execution

- Program stop or end

- Chuck clamp and unclamp on lathes

In my shop, I always say that G-code draws the path, but M-code keeps the machine alive. Without correct M-code logic, even a perfect toolpath will fail.

How M-code works together with G-code

M-codes are executed line by line inside a CNC program. They trigger physical actions on the machine while G-code defines motion.

For example, the machine will not cut unless:

- The spindle is running at the correct speed

- The tool is fully clamped

- The coolant is active when needed

This cooperation is why experienced machinists always review M-codes before pressing cycle start.

The Structure, Syntax, and Common Types of M-Codes?

Many errors come from assuming M-codes are universal. They are not. Understanding their structure is the first step to using them safely.

An M-code usually starts with the letter “M” followed by a number that triggers a specific machine action, though meanings can vary by machine and control system.

Basic structure of an M-code command

A simple M-code looks short, but its effect can be large.

Example format:

- M03 → Spindle on, clockwise

- M05 → Spindle stop

- M08 → Coolant on

- M09 → Coolant off

These commands are short by design. CNC controls1 must read them fast and without ambiguity.

Common categories of M-codes

Over the years, I group M-codes into practical categories when training new staff.

| Category | Typical Function |

|---|---|

| Spindle control2 | Start, stop, direction |

| Coolant control | Flood, mist, off |

| Tool control | Tool change, tool clamp |

| Program flow | Stop, optional stop, end |

| Fixture control | Chuck or clamp actions |

This grouping helps engineers understand intent instead of memorizing numbers.

Standard vs machine-specific M-codes

Some M-codes are widely shared. Others are defined by the machine builder.

For example:

- M03 and M05 are almost universal

- Custom M-codes may control probes, robots, or pallet systems

This difference becomes critical when outsourcing machining across regions or suppliers.

M-Codes Across Machines and CNC Control Systems?

Many sourcing problems appear when programs move between machines. Engineers expect the same result, but the machine reacts differently.

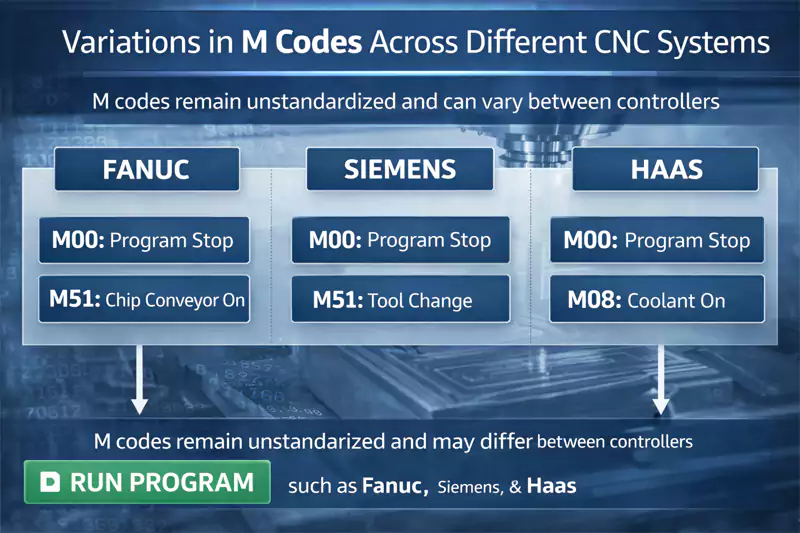

M-codes are not fully standardized and can behave differently across CNC controllers such as Fanuc, Siemens, and Haas.

Differences between common control systems

In daily production, I often see these patterns:

| Control System | Typical Behavior |

|---|---|

| Fanuc3 | Stable standard M-codes, flexible customization |

| Siemens4 | Strong logic integration, more parameters |

| Haas5 | User-friendly, some unique M-code definitions |

Even when the M-code number is the same, the timing or conditions may differ.

Why this matters in outsourced machining

When a European engineer sends a program to a Chinese factory, assumptions can break.

Common risks include:

- Coolant timing differences

- Tool change confirmation delays

- Optional stop behavior mismatch

At Allied Metal, we always review customer programs and rewrite M-code sections when needed. This step prevents surprises on the shop floor.

Practical Applications, Risks, and Safety Considerations?

M-codes show their true value in real production, not in textbooks. They also carry the highest risk when used incorrectly.

Correct M-code logic ensures safe operation, while incorrect usage can cause crashes, scrap, and machine damage.

Real-world case study from my shop

Several years ago, we produced custom aluminum housings for an industrial automation client.

Project parameters

| Item | Value |

|---|---|

| Material | Aluminum 6061-T66 |

| Machine | 3-axis vertical machining center |

| Control | Fanuc |

| Batch size | 500 units |

| Tolerance | ±0.02 mm |

| Cycle time | 6.5 minutes per part |

Issue

The original program used M08 coolant activation too late in the cycle.

Result

- Tool temperature increased

- Surface finish degraded after 120 parts

- Tool life dropped by 30%

Correction

We adjusted the M-code sequence to activate coolant before tool engagement.

Outcome

- Stable surface finish

- Full batch completed without tool failure

This small M-code change saved both time and cost.

Common M-code mistakes

From my experience, these mistakes appear often:

- Forgetting to stop the spindle before tool change

- Using optional stops incorrectly in production runs

- Assuming fixture M-codes are the same across machines

Each one can shut down production in seconds.

Safety considerations

M-codes often control safety-related actions7. This is why we test them carefully before mass production.

A single wrong clamp command can damage a fixture or injure an operator.

M-Code vs G-Code and Who Needs to Understand Them?

Many people ask if they really need to understand M-codes when outsourcing machining. The answer depends on their role.

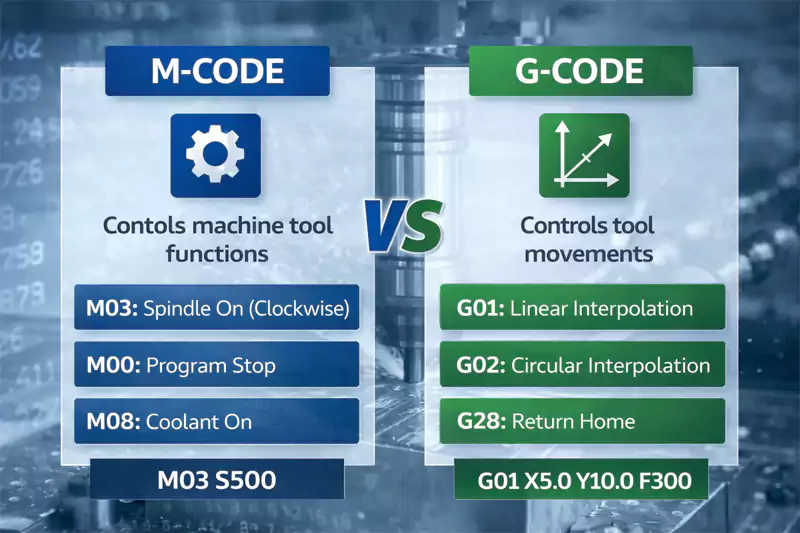

G-code defines motion, while M-code controls machine behavior, and both are essential for predictable CNC production.

Key functional differences

| Aspect | G-Code | M-Code |

|---|---|---|

| Purpose | Tool movement | Machine actions |

| Focus | Geometry | Behavior |

| Visibility | CAD/CAM output | Often manual or edited |

| Risk | Dimensional error | Safety and process failure |

Who really needs to know M-code

Design engineers do not need to write M-codes. Procurement managers do not need to memorize them. But both should understand their impact.

When sourcing custom CNC parts, knowing how a supplier manages M-codes helps you judge:

- Process maturity

- Risk control

- Production stability

This understanding builds trust between buyer and manufacturer.

Conclusion

M-code may look simple, but it controls the most critical machine actions. In my experience, mastering it is key to safe, consistent, and scalable CNC machining.

-

Exploring CNC controls will deepen your knowledge of how machines execute commands, improving your programming efficiency. ↩

-

Exploring spindle control will enhance your knowledge of machine operations and improve your CNC skills. ↩

-

Understanding Fanuc Control Systems. CNC controllers for reliable, high-performance CNC systems. ↩

-

Learn more about the Siemens control system product range. ↩

-

Fast, smart, and powerful, the Haas CNC control offers a simple, intuitive interface that’s easy to learn and use. ↩

-

Understanding Aluminum 6061-T6's properties can enhance your material selection for projects, ensuring optimal performance. ↩

-

Learn about the importance of safety-related actions in CNC machining to prevent accidents and ensure smooth operations. ↩