Parts moving during machining can ruin a job instantly. Poorly held workpieces lead to inaccuracy, broken tools, and dangerous situations, threatening your project's success and safety.

Workholding refers to any device or method used to securely locate and hold a workpiece in a stable, fixed position during a manufacturing operation like CNC machining, ensuring quality and safety.

In my experience running Allied Metal, the success of any CNC machining job comes down to one fundamental: good workholding. You can have the most advanced machine and the perfect cutting tool, but they are useless if the workpiece moves. Essentially, workholding is the method or device—whether a simple vise, a custom jig, or a complex fixture—used to stabilize the part. Getting this foundation right is what ensures the accuracy, safety, and efficiency of the entire operation. For an engineer like David who lives by precision, understanding that how a part is held is just as critical as how it is designed is the key to successful manufacturing.

What Is the Core Meaning of 'Workholding' in a Machine Shop?

You hear machinists talk about vises, fixtures, and chucks. What do all these terms fall under, and what is the fundamental purpose of "workholding"?

Workholding is the broad term for any method or device used to securely locate and firmly clamp a workpiece, preventing any movement during a machining or manufacturing operation.

Diving Deeper into the Meaning of Workholding

In any machine shop, "workholding" is a term that encompasses all the tools, devices, and techniques used to hold a part (the workpiece) in place while it's being worked on. Think of it this way: a CNC machine can move its cutting tools with incredible precision, often to within a thousandth of an inch or less. But that precision is completely meaningless if the part it's trying to cut isn't held in a perfectly stable and known position. Any movement of the workpiece during the operation will directly translate into a dimensional error on the final part.

The core meaning of workholding involves two distinct but related actions:

- Locating: This is about positioning the workpiece accurately. The workholding device1 must place the part in a specific, repeatable location relative to the machine's coordinate system (its X, Y, and Z axes). This ensures that features are machined in the correct places as defined by the design.

- Clamping: This is about applying force to hold the workpiece securely against its locating points. The clamping force must be strong enough to resist the forces generated by the cutting tool, which can be significant, but not so strong that it distorts or damages the workpiece itself.

Workholding involves common devices like vises, jigs, and fixtures2, but the core idea is universal — it’s all about making the workpiece completely stable from the machine’s point of view. This stability is what allows the CNC system’s precision to be fully and accurately transferred to the part.

What Are the Fundamental Principles of Good Workholding?

Securely holding a part seems simple, but there's a science to it. What are the key principles that guide the design and use of effective workholding solutions?

Good workholding is based on key principles: accurately locating the part, supporting it against cutting forces, clamping it securely without distortion, and ensuring tool access and overall rigidity.

Diving Deeper into Workholding Principles

Effective workholding isn't just about clamping a part down as hard as you can. It's a systematic approach based on several key principles. For an engineer like David, understanding these principles helps in designing parts that are easier to hold and therefore easier to machine accurately.

-

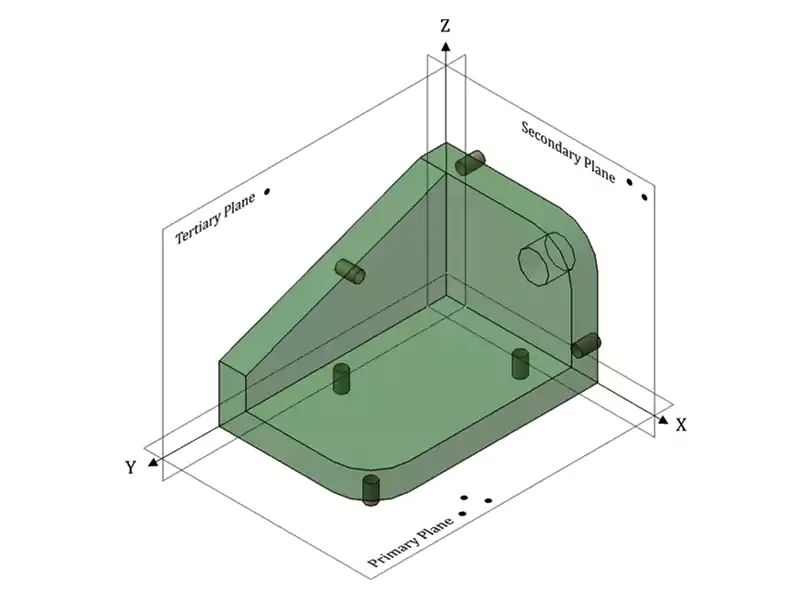

Locating (Positioning): The workpiece must be positioned precisely. The most common method for this is the 3-2-1 principle for prismatic (block-like) parts:

- Three points define a primary plane, usually the bottom surface of the part. This restricts 3 degrees of freedom (one vertical movement and two rotational).

- Two points on a second plane (a side) define a line. This restricts 2 more degrees of freedom (one linear movement and one rotational).

- One point on a third plane (an end) defines a point. This restricts the final degree of freedom (the last linear movement).

By using this 3-2-1 method, the part is constrained in all six degrees of freedom, ensuring it's in a known and repeatable position.

-

Supporting: The workpiece must be supported to prevent it from bending, vibrating, or deflecting under the force of the cutting tool. Supports should be placed directly opposite clamping force3s and under areas where heavy cutting will occur.

-

Clamping: The clamping force must be sufficient to hold the workpiece against the locators and resist cutting forces, but it shouldn't distort or damage the part. Clamping forces should always be directed into the solid locators and supports, not into open space.

-

Rigidity: The workholding device itself must be strong and rigid enough to not flex or move during the machining operation. The entire setup, from the machine table to the fixture to the workpiece, should be as rigid as possible.

-

Tool and Operator Access: The workholding setup must allow the cutting tool to access all the features that need to be machined without interference. It should also be easy and safe for the operator to load and unload parts.

The reason I believe that good workholding ensures “accuracy, safety and efficiency” is a direct result of the proper application of these basic principles.

What Are the Different Types of Workholding Devices Used in CNC Machining?

Vises are common, but what other methods are used to hold parts? What's in the machinist's toolkit for securing different shapes and sizes of workpieces?

Common workholding devices include machine vises, chucks (3-jaw, 4-jaw, collet), clamps, and custom-made jigs and fixtures. Specialized options like magnetic or vacuum chucks are also used.

Diving Deeper into the Workholding Arsenal

A well-equipped machine shop like Allied Metal uses a range of workholding devices to accommodate the variety of parts we produce for clients. The choice of device depends on factors like the part’s shape, size, material, machining requirements, and production volume — with vises, jigs, and fixtures being the most commonly used categories.

Here are some of the most common types:

1. General-Purpose Workholding:

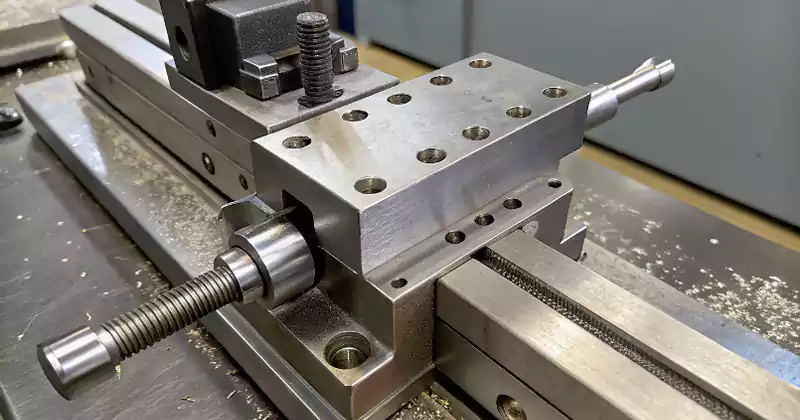

- Vises: The most common workholding device for milling. A machine vise clamps a prismatic (square or rectangular) workpiece between two jaws. High-quality precision vises are essential for accuracy.

- Chucks: Used primarily for holding cylindrical parts on a lathe (for turning) or on a rotary table in a mill.

- 4-Jaw Chucks: Each jaw moves independently, allowing for gripping of square, rectangular, or irregular shapes, and for precise centering.

- Collet Chucks: Use collets to grip round stock with high accuracy and gripping force, excellent for smaller diameters.

- Clamps: Strap clamps, toe clamps, and other clamping systems are used to hold down large or irregularly shaped parts directly to the machine table or on a fixture plate.

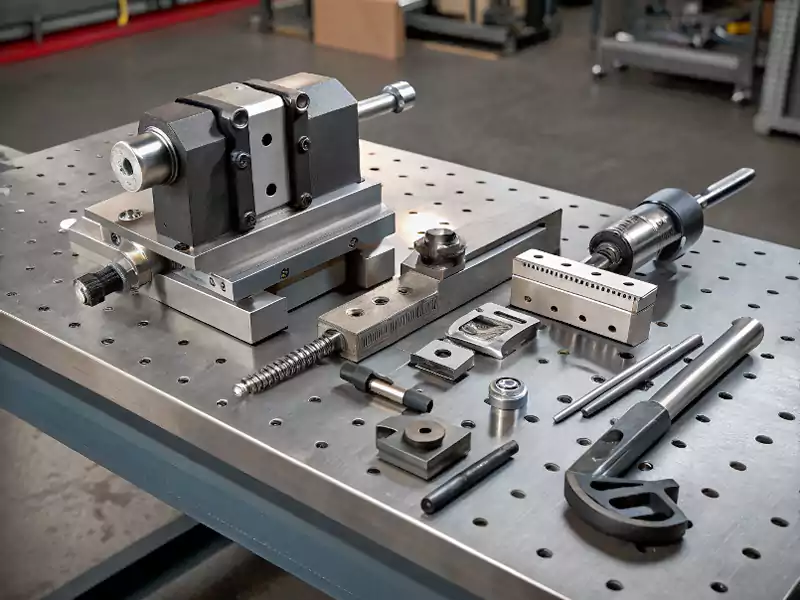

2. Modular Workholding:

- This involves using a system of standardized components (like grid plates, blocks, and clamps) to build a custom workholding setup.

- Tombstones: A common modular fixture used on Horizontal Machining Centers (HMCs). They are vertical towers that allow multiple parts to be mounted on their different faces, maximizing machine uptime.

3. Custom Workholding:

- Fixtures: A custom device designed to hold a specific part for machining. Fixtures provide excellent location and support for complex shapes or high-volume production, ensuring repeatability.

- Jigs: A device that both holds the work and guides the cutting tool. Jigs are more common in manual operations like drilling but the principle of guiding a tool or process is still relevant.

4. Specialized Workholding:

- Magnetic Chucks: Use powerful magnets to hold ferrous (iron-containing) materials. Great for surface grinding and light milling of flat parts.

- Vacuum Chucks: Use suction to hold thin, flat, or non-magnetic materials like aluminum or plastics without mechanical clamps.

The right choice depends on balancing factors like setup time, cost, part geometry, and production volume.

How Is Workholding Specifically Applied to CNC Machines?

Workholding has been around for ages. How does the high-speed, automated environment of CNC machining change the requirements and application of workholding?

Workholding for CNC machines demands high rigidity, extreme repeatability for batch production, and often integrates automation like hydraulic/pneumatic clamping. Fixtures must also be accounted for in CAM programming.

Diving Deeper into CNC-Specific Workholding

While the fundamental principles of workholding remain the same, the application in a CNC machining environment presents unique demands and opportunities. The high speeds, powerful cutting forces, and automated nature of CNC put a greater emphasis on certain aspects of workholding compared to manual machining. For engineers, who rely on CNC for their parts, these specifics are what guarantee quality.

-

High Rigidity and Force Management:

- CNC machines are capable of very aggressive cutting parameters (high feed rates and deep cuts). The workholding must be extremely rigid to withstand these significant forces without any vibration or deflection. Any movement would be detrimental to both part accuracy and tool life.

-

Repeatability:

- One of the main advantages of CNC is its ability to produce many identical parts. The workholding must support this by allowing each workpiece to be loaded into the exact same position, every single time. This is where custom fixtures or high-quality vises with workstops excel.

-

Automation Integration:

- In production environments, workholding is often automated. Hydraulic or pneumatic clamps can be activated by the CNC machine's program (using M-codes) to automatically clamp and unclamp parts. This reduces cycle times and is essential for unattended machining or robotic part loading.

-

CAM and Simulation:

- The workholding device itself (the vise, clamps, fixture) is now part of the digital setup. In modern CAM software, the entire fixture is modeled along with the workpiece. This allows the programmer to simulate the toolpaths and check for any potential collisions between the cutting tool, the tool holder, and the workholding device. This is a critical safety and process validation step that is unique to CNC.

-

Multi-Part Setups:

- CNC machines, especially Horizontal Machining Centers (HMCs), are often set up to machine multiple parts in a single cycle to maximize efficiency. This is often achieved using tombstone fixtures, which are large towers with multiple mounting faces. A full tombstone of parts can be machined while the operator prepares another one offline, dramatically reducing machine downtime.

In the world of CNC machining, solid workholding makes all the difference — it helps you run faster, cut cleaner, and really get the most out of your machine.

Just How Important Is Good Workholding in CNC Machining?

Is workholding a minor detail, or is it a make-or-break factor? How much does the method of holding a part truly impact the final quality and success?

Good workholding is absolutely critical. It is the foundation for achieving part accuracy, ensuring operator and machine safety, and enabling efficient, high-speed machining. Poor workholding guarantees poor results.

Diving Deeper into the Critical Role of Workholding

In CNC machining, workholding isn’t just a setup step — it’s one of the most critical factors behind a successful operation. Even the most advanced machine can’t perform well if the part isn’t secured properly. Good workholding is the key to accuracy, safety, and efficiency — and here’s why.

1. Accuracy and Quality:

- Dimensional Accuracy: If a part shifts even slightly during machining due to inadequate clamping force, all subsequent cuts will be out of position, leading to scrapped parts. The workholding must hold the part to the same or higher level of precision as the machine itself. For David's challenge of meeting stringent tolerances, this is non-negotiable.

- Surface Finish: Vibration or chatter caused by poor support or rigidity in the workholding setup will be directly transferred to the part's surface, resulting in a poor finish. A rigid setup allows for smooth, clean cuts.

- Repeatability: For multi-part production, consistent workholding ensures that every part is a faithful copy of the last.

2. Safety:

- This is the most important aspect. CNC machines generate immense torque and cutting forces. A workpiece that comes loose can be ejected from the machine at high speed, posing a severe danger to the operator and anyone nearby. It can also cause catastrophic damage to the cutting tool, tool holder, spindle, and other parts of the machine. Proper workholding is the primary safety measure against such events.

3. Efficiency and Productivity:

- Higher Speeds and Feeds: A rigid, secure workholding setup allows the machinist to use more aggressive cutting parameters (higher speeds, feeds, and deeper cuts) without fear of part movement or vibration. This directly reduces cycle time and increases throughput.

- Reduced Setup Time: Well-designed workholding, especially modular systems or custom fixtures for repeat jobs, can drastically reduce the time it takes to set up a job.

- Unattended Machining: Reliable and often automated workholding is a prerequisite for running machines "lights out" or with minimal supervision, a key goal in modern manufacturing.

In short, workholding is the foundation upon which every successful machining operation is built. It's an area where cutting corners will always lead to bigger problems down the line.

Conclusion

Good workholding is the foundation of precision CNC machining. Securely locating and clamping the workpiece is essential for achieving part accuracy, ensuring safety, and maximizing manufacturing efficiency.

-

Discovering various workholding devices can help you choose the right one for your projects, improving efficiency and accuracy. ↩

-

Learn about the essential tools like vises, jigs, and fixtures that enhance machining efficiency and accuracy in your work. ↩

-

Learning about clamping force can help ensure that your workpiece is held securely without causing damage, enhancing machining quality. ↩

Pingback: What is Turning in Machining? - CNC Machining Supplier From China

Yo, tried some spins on sg77slot. Got a couple small wins, nothing crazy. Site’s easy to navigate though, which is a plus. Check them out: sg77slot