Table of Contents:

Reverse Engineering Services: Core Solutions for Precision Replication and Innovative Designs

- November 27, 2024

- Tony

- Last updated on November 13, 2025, by Lucy

After 20+ years in precision manufacturing, I’ve reverse engineered everything from obsolete industrial parts to complex aerospace components. Here’s the thing most people don’t get: reverse engineering isn’t just copying—it’s understanding, improving, and sometimes saving a production line that’s dead in the water.

1. What is reverse engineering services?

When a critical machine breaks down, and the OEM says the part is discontinued—that’s when you need real reverse engineering. This isn’t just taking a picture; it’s about recreating a part with higher precision than the original, especially if the original didn’t even have a digital drawing

Reverse Engineering is the precise science of turning an existing physical component into a fully editable 3D CAD model and a complete manufacturing blueprint. It is the key to life cycle management, design improvement, and guaranteeing fitment when old documentation is lost or non-existent.

2. Workflow of Reverse Engineering Services

- Data Acquisition: Using a high precision 3D scanner to obtain detailed data about the physical part.

- Data Processing and Modeling: The scanned data is converted into a digital 3D model, which is usually post-processed using CAD software.

- Manufacturing & Processing: Processing and production of the part based on the generated digital model, using e.g. CNC machining or 3D printing technology.

- Quality Inspection: Accurate inspection methods are used to confirm the fit and functionality of the part to the original.

3. Key Technologies and Tools for Reverse Engineering services

Reverse engineering leverages advanced techniques to analyze, replicate, and enhance existing products or components. Key technologies and tools include:

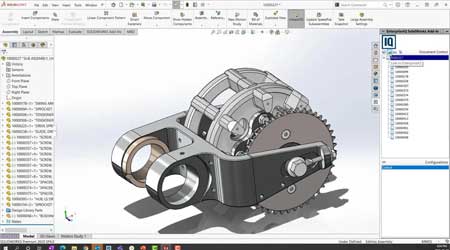

CAD Software

Scanned data is processed in software like SolidWorks or AutoCAD, allowing engineers to refine designs and generate new models.

Coordinate Measuring Machines (CMM)

High-precision tools measure part dimensions and integrate with scan data for comprehensive analysis.

Prototyping and CNC Machining

Equipment like 3D printers and CNC machines rapidly produce prototypes or finished parts. 3D printing handles complex models, while CNC machining offers precision across diverse materials.

These tools and technologies streamline replication, optimization, and redesign, making reverse engineering essential for part replacement and innovation.

📌Case Study: Bringing Obsolete Machinery Back to Life

Let me share a past project that shows reverse engineering in action. We had a client with a 25-year-old packaging machine – the manufacturer was long out of business, and they needed replacement gears that were completely worn out.

The Challenge:

- Part: Drive gear assembly for packaging machine

- Original Status: No drawings, no CAD data, severe wear on existing parts

- Material: 4140 steel, heat-treated to RC 45-48

- Critical Dimensions: 127mm diameter, 32-tooth profile, 20mm bore with keyway

Our Approach: We started with a structured light 3D scanner to capture the worn gear geometry. The scan data showed uneven wear across the tooth profile – we couldn’t just copy the worn part. Our engineers used the scan as a baseline in SolidWorks, then applied standard gear design principles to recreate the original tooth profile.

Manufacturing Details:

- Process: CNC turning and hobbing

- Machine: 5-axis CNC machining center

- Tolerance: ±0.02mm on critical dimensions

- Surface Finish: 0.8μm Ra on gear teeth

- Lead Time: 5 days from scan to finished parts

The Result: The client got a set of 4 replacement gears that fit perfectly. Total cost was 60% less than replacing the entire machine, and they were back in production within a week. The bonus? We improved the gear material to 4340 steel for better wear resistance.

5. Industries We Serve

Reverse engineering is widely used across almost all manufacturing industries. Here are some key applications:

- Automotive: Obsolete engine components, transmission parts

- Aerospace: Aging aircraft components, custom fittings

- Medical: Legacy equipment parts, custom surgical tools

- Industrial: Machinery components, custom fixtures

- Military Equipment Development:provides accurate replacement parts and design upgrades for high-tech systems.

- Cultural Relic Restoration: used to digitally reconstruct and restore cultural relics, offering innovative solutions for preservation.

6. Why Choose Our Reverse Engineering Service?

We Don’t Just Copy – We Improve Twenty years of machining experience means we can spot design flaws and material limitations that scanning alone won’t reveal.

Full In-House Capability From scanning to final part production, we handle everything under one roof. No subcontracting, no communication gaps.

Fast Turnaround When You Need It Most Emergency breakdown? We can often deliver replacement parts in days, not weeks.

Cost-Effective Solutions Typical reverse engineering projects cost 60-80% less than equipment replacement.

7. Common Questions About Reverse Engineering

Depends on the method. Scanning: ±0.02-0.1mm. CMM verification: ±0.002mm. We match or exceed the accuracy of the original manufacturing process.

Yes, but we typically disassemble, scan individual components, then model the assembly. More complex and expensive, but doable.

Depends on extent. Minor wear? We can interpolate original dimensions. Major damage? May need a second sample or make educated assumptions.

Generally yes, especially for replacement parts or parts you own. Patent infringement and trade secret issues can arise—consult legal counsel if concerned.

Typical: 2-4 weeks. Rush service: 1-2 weeks. Emergency: As fast as 5-7 days (premium pricing).

Yes, that’s our core business. Reverse engineering → CNC machining → delivered parts. Or we can provide documentation for you to manufacture elsewhere.

Summary (Reverse Engineering Services)

Good reverse engineering combines advanced technology with old-school machining knowledge. It’s not about having the fanciest scanner – it’s about having engineers who understand how parts are supposed to work and how to make them better.

Got a tricky part situation?

Reach out – I’m always happy to look at challenging projects and give you my straight-shooting opinion on whether reverse engineering makes sense for your application.