Table of Contents:

Aerospace CNC machining: The Expert's Guide to Flight-Ready Parts

- December 11, 2024

- Tony

- Last updated on October 29, 2025 by Lucy

With over 20 years of CNC machining experience, I can confidently tell you: in aerospace, there’s no such thing as “close enough.” The difference between a successful flight and catastrophic failure often comes down to tolerances finer than a human hair.

1. What is aerospace CNC machining?

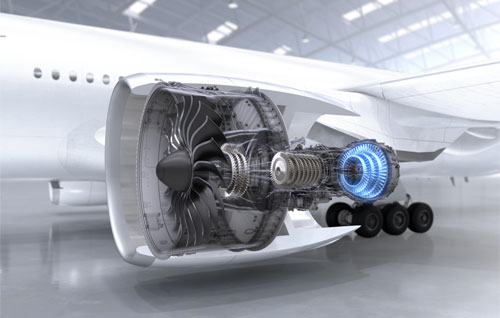

Aerospace CNC machining refers to uses computer-controlled technology to produce high-precision parts. Automated machines perform cutting operations based on preset programs, improving accuracy and efficiency. Due to the industry’s need for exceptional precision, CNC technology is widely used to manufacture aerospace components.

Why is accuracy so important in aerospace manufacturing?

In aerospace, precision is critical. Any small dimensional deviation can affect the performance, safety, and stability of a vehicle.

For example, the turbine blades of an aircraft engine must be precisely matched to other components, or they could lead to serious failure. CNC machining enables extremely tight tolerances to be achieved, ensuring that each component meets the design specifications, thereby improving overall system reliability and safety.

What Makes Aerospace CNC Different?

Precision That Actually Matters

We’re not talking about typical machine shop tolerances. In aerospace, ±0.01mm is often the starting point. I’ve seen components rejected for being 2 microns out of spec – that’s 1/30th the width of a human hair.

Materials That Defy Conventional Machining

2. Common parts of aerospace CNC machining

CNC machining is essential in the aerospace industry for producing complex, high-precision parts. Key applications include:

Turbine blades, compressor blades, and combustion chamber parts, requiring high precision due to extreme conditions. Multi-process machining like CNC milling and turning is used.

Aircraft fuselage, wings, and tail sections, which need to handle high aerodynamic loads. CNC machining improves efficiency and precision.

Satellite shells, thermal protection, and optical devices, requiring high shape and dimensional accuracy.

Parts such as seat brackets and hatches, meeting safety and lightweight design requirements, are CNC machined for consistency and accuracy.

CNC machining improves efficiency and accuracy for parts with complex shapes and high precision needs.

These crucial components need high precision, which CNC machining provides.

Designed for strength and precision, CNC machining ensures the required quality.

Beams, frames, and connectors, requiring high precision for complex shapes.

📌Case Study: Titanium Engine Mount Bracket

We had a client developing a new business jet engine. Their existing mount bracket was over-engineered and heavy, costing them payload capacity.

The Challenge:

- Original design: 15.2kg steel bracket

- Required strength: 180 kN ultimate load

- Vibration resistance: 0-2000 Hz spectrum

- Temperature range: -55°C to 300°C

- Timeline: 8 weeks for flight test parts

Our Approach:

- Material switch to Ti6Al4V titanium

- Topology optimization using finite element analysis

- 5-axis simultaneous machining for complex contours

- Stress relief and shot peening for fatigue life

Results:

- Final weight: 6.8kg (55% reduction)

- Achieved strength: 195 kN (8% margin)

- First natural frequency: 285 Hz (clear of engine excitation)

- Surface finish: 0.8μm Ra (better than required 1.6μm)

- Delivery: 6 weeks (25% faster than requested)

The bracket performed flawlessly during engine testing, and the client gained 8.4kg of additional payload capacity per aircraft. Sometimes the biggest wins come from weighing less.

3. Aerospace CNC machining of common materials

The selection of materials for aerospace parts is highly demanding, requiring light weight, high strength, and resistance to high temperatures and corrosion. Common aerospace CNC machining materials include:

Titanium alloys are strong, corrosion-resistant, and heat-resistant, making them ideal for engine components and structural parts.

Aluminum alloys are lightweight and strong, commonly used in aircraft fuselages, wings, and other structural parts.

Materials like Inconel alloys are known for their excellent heat resistance and are used in engine parts like turbine blades and combustion chambers.

Lightweight and strong, carbon fiber composites also resist high temperatures and are used in spacecraft shells and key structural components.

Stainless steel and other high-strength alloys are used for parts requiring high corrosion resistance and strength.

Engineering plastics offer good mechanical properties and temperature resistance, often used in non-structural parts to reduce weight and cost while maintaining strength and corrosion resistance.

4. The benefits of using CNC machining for aerospace parts

The benefits of CNC machining in aerospace manufacturing are clear, particularly for precision and tight tolerances. Key advantages include:

- Exceptional Accuracy:

With micron-level precision, CNC machining ensures parts meet stringent design specifications. - Enhanced Productivity:

Automated processes increase efficiency and reduce the need for manual intervention. - Complex Geometry Capability:

CNC machines can produce intricate shapes, such as turbine blades, to meet aerospace design requirements. - Precise Tolerance Control:

CNC machining guarantees accurate tolerance ranges, ensuring parts fit perfectly and maintain reliability. - Consistent Quality:

Whether for small batches or mass production, CNC machining delivers consistent quality, with each part adhering to design standards.

5. Shaping the Future of Flight with Allied Metal

The Future is Already Here

Additive Manufacturing Integration

We’re now 3D printing complex Inconel components and finish-machining critical surfaces. The best of both worlds.

Our machines now predict tool failure before it affects part quality. We’re preventing errors rather than detecting them.

Digital Twins

Every physical component has a digital counterpart with complete manufacturing history.

Allied Metal is a trusted partner in the aerospace industry, known for its advanced technology and extensive experience. Whether it’s producing complex parts or machining high-quality materials, it delivers precise, efficient solutions that meet exacting standards. With expertise in working with complex parts and tight deadlines, Allied Metal is the ideal partner for high-precision, high-quality custom aerospace CNC machining services.

6.Different machining processes for aerospace CNC machining

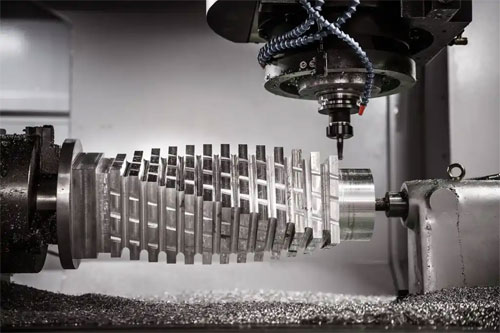

CNC machining is crucial in producing aerospace parts due to its precision and ability to handle complex shapes. Common processes include:

CNC Milling is widely used for machining flat surfaces, curves, slots, and holes. It allows for cutting in multiple directions, making it ideal for complex parts like wing structures and engine components.

Turning is used for machining shaft parts, where a rotating workpiece and fixed tool remove material. It’s commonly applied to parts like bearing housings and shafts, ensuring high dimensional accuracy.

Electrical Discharge Machining (EDM) is perfect for hard materials and complex shapes, particularly for creating holes in tough materials like titanium and Inconel alloys. It uses electric sparks to remove material, making it ideal for precision work.

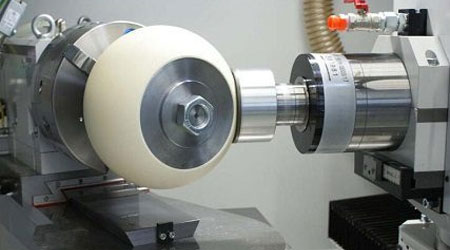

Grinding improves the surface accuracy and finish of parts. CNC grinders can control the amount of material removed, making them suitable for high-precision parts like those in aero-engines.

CNC drilling and boring are used for creating precise holes in aerospace parts. These processes ensure accurate positioning and sizing, which is essential for spacecraft components.

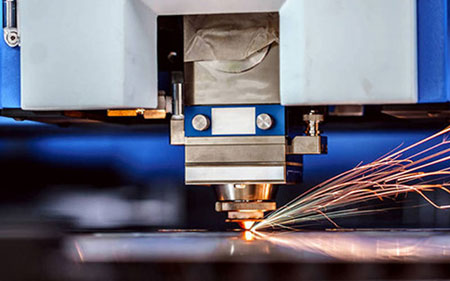

Laser cutting is a non-contact method for cutting thin sheets or intricate shapes. It uses a focused laser beam to quickly and accurately cut metals like aluminum and titanium, ideal for high-precision aerospace parts.

7. Summary

CNC machining is essential in aerospace for creating precise and complex parts needed for safe and high-performing aircraft and spacecraft. As technology advances, the demand for more accurate, lightweight, and durable components grows. In the future, new technologies like automation and AI will enhance CNC machining, helping companies meet the industry’s evolving needs more efficiently.