Table of Contents:

Complete Guide to Medical CNC Machining

- January 6, 2025

- Tony

- Last updated on October 28, 2025 by Lucy

After 25 years in medical manufacturing, I can tell you this: there’s no room for “close enough” when you’re making parts that go inside human bodies. The difference between a successful implant and a failed one often comes down to microns.

Let me walk you through what really matters in medical CNC machining – from the operating room to the production floor.

1. CNC machining methods in the medical industry applications

CNC Milling

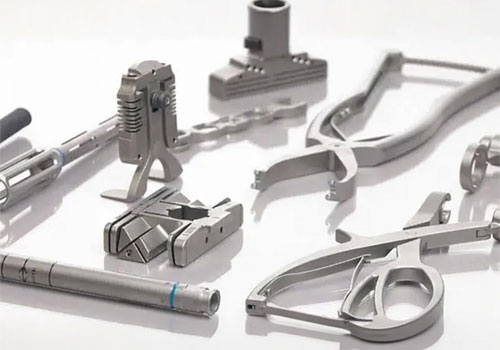

CNC milling is the removal of workpiece materials by rotating cutting tools, which is suitable for the manufacture of precision medical devices in the medical industry, such as surgical tools and surgical instruments.

High-precision CNC milling can ensure that the size and shape of the parts meet strict standards and avoid errors in manual operation.

CNC turning

CNC turning is mainly used for machining rotationally symmetrical components such as pipes, threads, or circular implants.

Certain components in the medical industry, such as parts of the structure of prosthetic limbs and dental implants, can be processed with high precision by CNC turning technology.

CNC grinding

CNC grinding is usually used for medical components that require very high surface accuracy and can produce smooth surfaces and very high dimensional accuracy.

Precision grinding is typically used to produce critical components such as orthopedic implants, surgical instruments, medical probes, endoscopic components, and more.

3D printing and application in medical treatment

3D printing technology is becoming a powerful complement to CNC machining, especially in the medical industry.

Through 3D printing, manufacturers can produce personalized medical devices and surgical tools, reducing tooling costs and time delays associated with traditional manufacturing methods.

It also plays a huge role in customized medical implants (e.g., custom prosthetics, dental implants, human organs, teaching aids, etc.).

Rapid Prototyping in the Medical Field

Rapid Prototyping (RP) is a technology that rapidly generates part prototypes through CNC machining and 3D printing, enabling rapid design verification and accelerating the product development process.

In the medical industry, rapid prototyping is widely used for medical device prototyping, as well as preoperative simulation and other applications.

Laser Processing and Other Advanced Processing Technologies

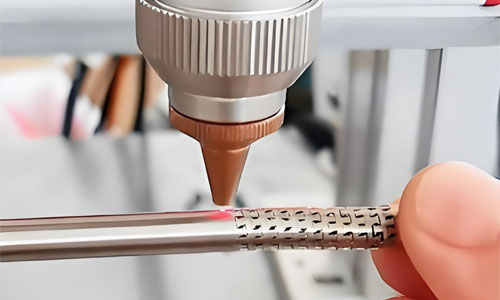

The application of laser processing technology in the medical industry is becoming more and more widespread, especially in areas requiring precision cutting and engraving.

Laser cutting allows for the processing of complex-shaped medical device components and maintains the integrity and accuracy of the material.

2. Advantages of CNC machining in the medical industry

- Precision and Consistency:

CNC technology ensures high precision, meeting the strict requirements of the medical field. It delivers consistent results in repeated processes, ensuring that all products comply with industry standards. - Customization and Flexibility:

This process allows for tailored solutions, which is essential in the medical sector where devices often need to be customized for individual patients. CNC processing makes this possible. - Faster Production and Lower Lead Times:

With CNC equipment, production is more efficient, reducing the need for manual labor. This enables quicker turnaround times, helping manufacturers respond faster to market and customer demands. - Reduced Costs and Improved Material Efficiency:

CNC processes maximize material use with precise cutting, minimizing waste. This reduces costs while maintaining quality compared to traditional methods. - Adherence to Health and Safety Standards:

Medical products must meet stringent safety and hygiene standards. CNC processing ensures the required precision and consistency, while surface treatments further guarantee the hygiene of the final product.

3. Applications of CNC machining in the medical industry

CNC machining of Medical Devices

CNC machining is crucial for producing high-precision medical devices, such as surgical instruments and diagnostic tools. It ensures the sharpness, accuracy, and safety required for these critical items.

Customized Implants

For personalized implants, including prosthetics, orthopedic devices, and dental replacements, CNC technology enables the creation of precise, patient-specific designs. This ensures an optimal fit that enhances both comfort and functionality.

Personalized Medical Equipment

This technology is also used to create customized medical equipment, such as orthotics and braces, which are tailored to individual patient needs based on body shape and medical conditions.

CNC machining medical hand plates and prototypes

CNC hand plates are an important part of the medical device development process. CNC processing allows for the rapid production of accurate prototypes, helping researchers and developers verify the feasibility of a design and make any necessary modifications.

CNC machining of biomedical materials

In processing advanced biomedical materials, such as bioceramics and alloys, CNC machining provides the necessary precision to meet the strict requirements of these high-performance materials.

Case Study: Titanium Spinal Fusion Cage

We had a neurosurgeon who was frustrated with off-the-shelf spinal cages. The fit was never quite right, and patient recovery times were longer than they should be.

The Challenge:

- Patient-specific geometry from CT scans

- Material: Ti6Al4V ELI (extra low interstitial)

- Porous structure for bone ingrowth (200-400 micron pores)

- Zero sharp edges, all radii >0.2mm

- Delivery: 5 days from scan to surgery

Our Approach:

- Hybrid manufacturing: 3D printed the complex lattice structure

- 5-axis CNC machining for critical load-bearing surfaces

- Electropolishing to achieve 0.1μm Ra surface finish

- 100% coordinate measurement machine inspection

Parameters:

- Dimensional accuracy: ±0.01mm on all critical features

- Surface finish: 0.08μm Ra (exceeded requirement)

- Pore size consistency: 350±25 microns

- Bioburden testing: Zero colony formation

- Surgical fit: Perfect first-time placement

The Outcome: The patient’s fusion occurred 3 weeks faster than with previous implants, and they returned to work 6 weeks earlier. Sometimes the smallest details make the biggest differences in recovery.

4. Impact of CNC Machining on the Healthcare Industry

- Driving Innovation and Customization:

CNC machining enables the creation of advanced, personalized medical devices tailored to individual patient needs. This innovation not only enhances treatment outcomes but also offers patients more options. - Improving Patient Comfort and Outcomes:

Custom devices and implants made through CNC technology improve patient comfort by ensuring a better fit with the patient’s body and health conditions, leading to better overall outcomes. - Transforming Production Models:

The adoption of CNC machining has streamlined medical device manufacturing. It shortens production cycles, reduces costs, and increases flexibility, making the process more responsive to demand. - Ensuring Regulatory Compliance and Quality:

Strict industry regulations require CNC manufacturing to meet high-quality standards. Manufacturers must ensure that each stage of production complies with these regulations to guarantee safety and effectiveness.

5. How to choose the right CNC machining outsourcing service provider?

As we all know, precision and quality are critical for medical parts. Numerical control machining is a key technology for producing medical parts and choosing the right CNC outsourcing partner is crucial.

Allied Metal is one of the leading CNC machining companies in China, providing precision CNC processing services with a focus on quality, accuracy, and industry expertise.

With certifications such as ISO 13485 and state-of-the-art machinery, we can provide medical parts that meet exacting standards. Whether it’s for prototyping or large-scale production, our experienced team ensures reliable, high-quality results.

6. Future Prospects: CNC Machining in the Healthcare Industry

AI-Assisted Machining

Our systems now predict tool wear before it affects part quality. We’re preventing errors rather than detecting them.

Sustainable Medicine

We’re reducing medical waste by 60% through better programming and material optimization. Green manufacturing saves lives AND the planet.

Conclusion

In summary, CNC machining is revolutionizing the medical industry with its precision, speed, and adaptability. As technology advances, it will become even more integral in shaping the future of medical devices and personalized treatments, driving innovation and improving patient care.