Table of Contents:

Mastering Stainless Steel CNC Machining: Expert Guide & Tips | Allied Metal

- February 24, 2025

- Tony

- Last updated on October 22, 2025 by Lucy

1. Introduction to Stainless Steel CNC Machining

Overview of Stainless Steel CNC Machining Technology

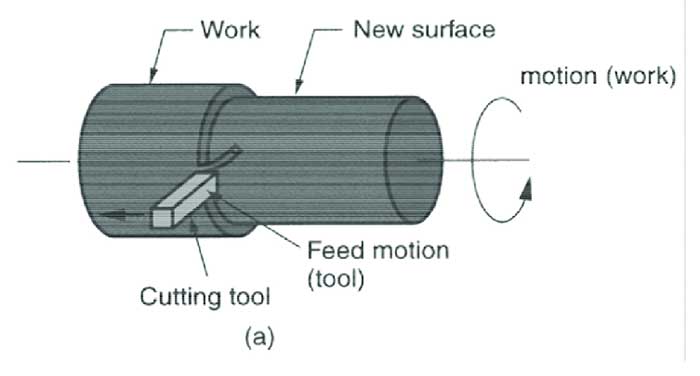

Stainless steel CNC machining uses computer-controlled machines to cut and shape stainless steel parts with high precision. It is highly efficient and ideal for creating complex components that must meet specific requirements.

Challenges and Requirements of Stainless Steel Machining

The stainless steel machining process is challenging due to the material’s hardness and strength, which can lead to rapid tool wear and thermal issues. To avoid these complications, special cutting tools and precise machine settings are required, ensuring quality and accuracy in every part produced.

2. Advantages of Stainless Steel CNC Machining

High Precision

One of the key benefits of CNC machining of stainless steel is its ability to achieve high precision. The advanced capabilities of CNC machines allow for accurate cuts with minimal error, which is crucial in industries like aerospace, automotive, and medical devices where precision is paramount.

Increased Productivity

Automation in the stainless steel machining process reduces the need for manual labor and minimizes human error, allowing for continuous production. CNC machines can operate around the clock, making them ideal for mass production, which leads to consistent quality and reduced manufacturing costs.

Ability to Create Complex Shapes

CNC machining can easily create complex shapes and intricate designs that are difficult to achieve using traditional machining methods. Stainless steel’s inherent strength and durability make it ideal for producing these highly detailed parts.

Better Surface Finish

The precision offered by CNC machining of stainless steel results in a smooth, clean finish, often reducing the need for additional post-processing. This is essential for parts used in industries that require high surface quality , such as medical devices or food production equipment.

Material Efficiency

The stainless steel machining process is highly material-efficient, as CNC machines are designed to minimize waste. By using the material more effectively, CNC machining reduces costs and prolongs the life of cutting tools.

3. Major Challenges in Stainless Steel CNC Machining

Tool Wear

The hardness of stainless steel is one of the primary challenges in the stainless steel machining process, as it causes rapid wear on cutting tools. This issue is exacerbated when working with high-alloy stainless steels, requiring specialized tools with advanced coatings to maintain performance.

Thermal Deformation

As heat builds up during the CNC machining of stainless steel, it can lead to thermal deformation, causing the material to expand and deform. This can result in dimensional inaccuracies that affect the quality of the final product. Managing cutting forces is crucial to minimize these thermal effects and ensure precise machining.

Heat-Affected Zone (HAZ) and Surface Quality

During the machining process, the heat generated can alter the properties of stainless steel near the surface, resulting in discoloration or reduced corrosion resistance. Proper control of heat during stainless steel machining is essential to maintain the appearance and functionality of the part.

4. Optimizing Stainless Steel CNC Machining: Solutions to Overcome Challenges

Adjusting Cutting Parameters

Fine-tuning cutting parameters like speed, feed rate, and depth of cut can significantly reduce tool wear and mitigate thermal deformation. This is essential in optimizing the stainless steel machining process to produce high-quality parts with minimal errors.

Choosing the Right Cutting Tools

Utilizing advanced cutting tools with coatings such as titanium nitride or ceramic coatings can extend tool life, improve cutting performance, and reduce wear, especially when machining tough stainless steel alloys.

Cooling and Lubrication

Effective cooling and lubrication during the CNC machining of stainless steel help reduce heat buildup and friction. This lowers the risk of thermal deformation and improves both part quality and tool longevity.

Automated Machining Paths

Automating machining paths optimizes the movement of tools and minimizes unnecessary operations, boosting productivity and ensuring greater stability during production, which is especially beneficial in high-volume stainless steel machining.

Case: Machining a Complex 316L Hydraulic Manifold

Talking about speeds, feeds, and coolant is one thing, but seeing how it all comes together on a challenging part is where the real learning happens. Let me share an example from our shop floor – a custom hydraulic manifold block we machined for a client in the industrial automation sector. This wasn’t just another job; it tested our understanding of stainless steel.

The Challenge: The client needed a manifold block from 316L Stainless Steel due to the corrosive nature of the hydraulic fluid. The design involved deep, intersecting internal fluid passages, multiple angled ports, and critical O-ring sealing faces that had to be perfectly flat and smooth to prevent leaks under high pressure (up to 400 Bar / 5800 PSI). 316L, being an austenitic stainless steel, loves to work-harden, especially during deep drilling and boring operations, making chip control and maintaining tolerances tricky.

Key Part Specifications & Our Approach:

- Material: 316L Stainless Steel (chosen for corrosion resistance)

- Critical Tolerances: <

- Internal Bore Diameters: ±0.01 mm (Essential for valve function)

- Port True Position (Angled Faces): Ø 0.05 mm (Ensures correct line connections)

- O-Ring Face Flatness: 0.008 mm (Critical for sealing under pressure)

- Surface Finish: Ra 0.4 µm on all sealing faces (Prevents O-ring damage and leaks)

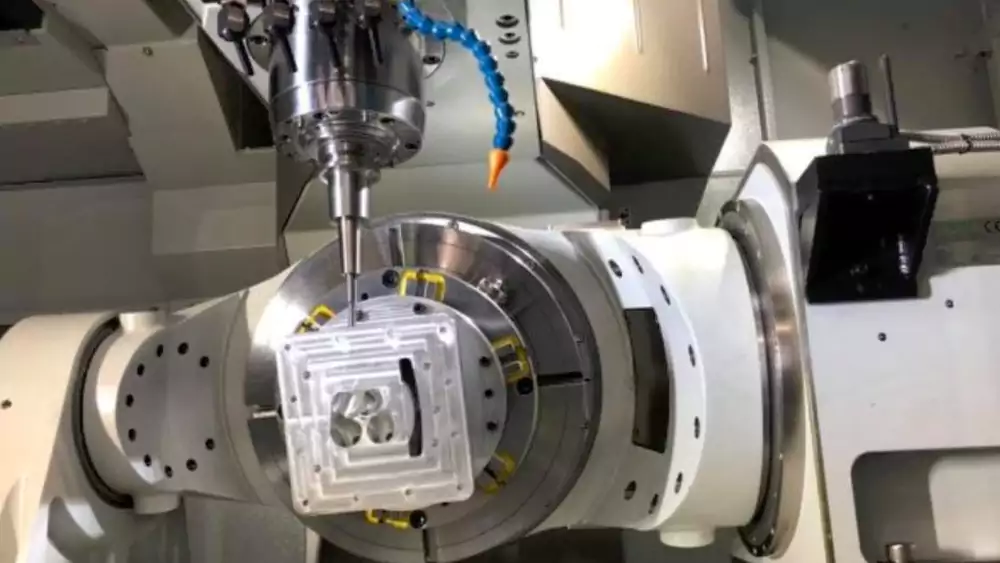

- Machining Process: Primarily 5-Axis CNC Milling & Precision Boring

How We Tackled It (The "Shop Floor Secrets"):

- Rigidity is King: We started by designing a robust, custom fixture to hold the block securely in our 5-axis mill. Any vibration would be fatal for tolerances and tool life with 316L.

- Tooling Selection: Forget standard tools. We used high-performance carbide drills with polished flutes and through-tool coolant channels specifically designed for stainless steel. For milling the sealing faces, we used indexable face mills with sharp, positive rake inserts optimized for finishing stainless.

- Speeds & Feeds – The Balancing Act: Here’s where experience counts. With 316L, you can’t go too fast (generates too much heat, work-hardens) or too slow (causes rubbing, also work-hardens). We started with conservative manufacturer recommendations and then carefully tuned the speeds (lower SFM) and feeds (higher chip load per tooth) on the machine, listening to the cut and watching the chip formation. For the deep drilling (over 8x diameter), we used a peck drilling cycle with full retracts to clear chips effectively.

- Coolant Strategy: Flooding isn’t enough. We utilized high-pressure (1000 PSI) through-spindle coolant. This blasts chips out of the deep holes and directly cools the cutting edge, drastically reducing heat buildup and preventing tool failure.

- Process Sequencing: We didn’t try to do everything at once. The process involved rough milling, semi-finishing passes (leaving minimal material), stress relief (a crucial intermediate step for stability on complex parts), and finally, precision finish milling and boring of the critical features.

The Result:

By applying these meticulous strategies, we produced manifold blocks that met all the client’s stringent requirements. The parts passed their 400 Bar pressure testing with zero leaks. More importantly, our understanding of how 316L behaves under the cutter allowed us to achieve consistent results across the entire production batch, delivering reliable components for their critical systems. Machining stainless isn’t just about following a recipe; it’s about understanding the material and adapting your technique.

5. How to ensure the quality of stainless steel CNC machining?

Automated Inspection

To maintain high standards in stainless steel machining, automated inspection systems are employed to monitor machining accuracy in real-time. This technology allows for quick adjustments to ensure that parts meet the required specifications, minimizing human error.

Surface treatment after CNC machining

Surface treatments like polishing, passivation, and coating play a vital role in improving the corrosion resistance and surface finish of stainless steel parts. These treatments are essential for parts used in harsh environments, ensuring longevity and performance.

Final Inspection

A final inspection is crucial to guarantee that all parts meet stringent quality standards before shipping. This step ensures the consistency and reliability of the finished components produced through CNC machining of stainless steel.

6. Future Trends in Stainless Steel CNC Machining

Looking ahead, the future of stainless steel machining will be driven by intelligent automation. As smart manufacturing techniques evolve, CNC machines will become increasingly capable of self-optimizing using real-time data. This will enhance both efficiency and accuracy, making it easier for manufacturers to stay competitive in the evolving market.

Additionally, emerging technologies like 5-axis CNC machining and laser cutting will revolutionize the stainless steel machining process. These innovations will allow for even greater flexibility, precision, and speed, enabling the production of more complex parts with faster turnaround times.

7. Conclusion

The CNC machining of stainless steel has proven essential for creating high-quality, precise parts. Despite challenges like tool wear, thermal deformation, and surface quality issues, advancements in techniques and technology are continuously improving the process.

As the demand for precision and efficiency increases, the stainless steel machining process will continue to evolve, offering new opportunities for manufacturers. With ongoing innovations in automation and tooling, the future of stainless steel CNC machining looks bright, ensuring stainless steel remains the material of choice for high-performance applications worldwide.