Struggling to create complex, custom shapes with consistent quality? Traditional methods can be slow and prone to errors. Forming milling offers a precise and efficient solution.

Forming milling is a CNC machining process. It uses a custom-ground cutter that has the exact inverse shape of the desired profile. This allows it to machine the complete form onto a workpiece, often in a single pass, ensuring high accuracy and repeatability.

When I first got into CNC machining, I was fascinated by the different ways we could shape metal. Forming milling, in particular, caught my eye because of its elegance and efficiency for specific tasks. It's a bit like having a special key cut for a very specific lock. Once you have that key, opening that lock becomes incredibly fast and repeatable. Let's explore this technique a bit more, and I think you'll see why it’s such a valuable process in a machinist's toolkit. Understanding its mechanics and applications can really open up possibilities for your designs, especially if you're like David, aiming for precision and efficiency.

How does Forming Milling actually create those intricate shapes?

Ever wondered how those perfectly uniform gears or unique grooves are made so consistently? It might seem complex, but the principle is quite straightforward. Forming milling makes it possible.

Forming milling works by using a rotating cutter ground to the exact negative profile of the desired shape. As this specialized cutter engages with and travels along the workpiece, it directly machines its unique geometry onto the material, effectively "forming" the surface.

To dive a bit deeper, the magic really lies in the cutter itself. Think of it as a sculptor's chisel, but one that's been perfectly shaped beforehand for a very specific detail.

The Custom Cutter: Heart of the Operation

The cutter is the star of the show in forming milling. It's not your standard end mill; instead, it's custom-ground1 from materials like High-Speed Steel (HSS)2 or solid carbide to precisely match the inverse of the profile you want to create. So, if you need a convex curve on your part, the cutter will have a concave curve. This custom nature means the initial tooling investment can be higher, but the payoff comes in production. I recall a project where a client approached us to custom-make parts featuring unique mortise-and-tenon joints, requiring the machining of several hundred units. Using a form cutter saved us countless hours compared to trying to achieve the same profile with multiple standard tools and operations.

Machine and Movement Precision

The CNC machine plays a crucial role by controlling the cutter's movement with extreme precision. The feed rate3 (how fast the cutter moves across the workpiece) and spindle speed4 (how fast the cutter rotates) are carefully calculated. For many applications, especially shallower profiles, the entire form can be machined in a single pass. This is a huge time-saver. For deeper or more complex forms, or when working with tougher materials, multiple passes might be programmed to gradually achieve the final shape, ensuring accuracy and minimizing stress on the tool and workpiece. It is precisely this level of precise control that enables purchasing managers to obtain highly accurate and consistent machined parts.

How does Forming Milling stack up against other milling methods?

With so many milling options available, it's easy to get confused. When should you specifically opt for forming milling? Understanding its unique advantages will clarify its specific role.

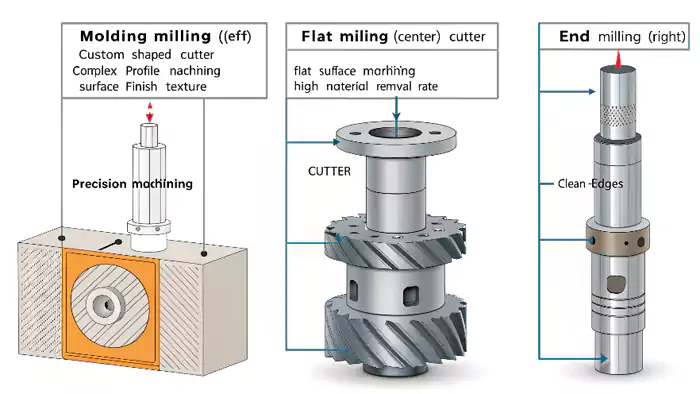

Forming milling excels at producing specific, complex profiles with high repeatability and speed once set up. Other methods like plain or end milling create simpler geometries or require multiple operations and tools to achieve similar complex results, often taking longer.

Let's break down the key differences to help you see where forming milling shines. It's not always the best choice for every job, but for certain applications, it's unbeatable.

Key Distinctions from Other Milling Types

The most obvious difference is the tooling. Standard milling operations like plain milling (creating flat surfaces), end milling (creating slots, pockets, and peripheral cuts), or face milling (machining large flat surfaces) use general-purpose cutters. Forming milling, however, requires a cutter shaped to the specific profile. This makes it less flexible for one-off jobs with unique profiles because you need that custom tool. But for repeat jobs or high-volume production of a specific shape, it's incredibly efficient.

Here’s a simple comparison:

| Feature | Forming Milling | End Milling (for complex profile) | Plain Milling |

|---|---|---|---|

| Profile Complexity | High, custom shapes | Achievable, but needs multiple passes/tools | Simple, flat surfaces |

| Tooling | Custom, profile-specific | Standard, multiple may be needed | Standard |

| Setup Time | Potentially higher (custom tool) | Lower per tool, but multiple setups | Lower |

| Cycle Time (complex) | Often significantly faster | Slower, multiple operations | Not applicable |

| Consistency | Very high | Operator/setup dependent | High for flat |

I've often advised clients that if they have a part with a unique groove, spline, or gear tooth profile that needs to be made in quantity, forming milling is the way to go. While an end mill could trace out a complex path, a form cutter does it in one go, ensuring every part is identical and often with a better surface finish, just as my insight suggests: "It’s a smart choice when you need consistent, complex profiles without a lot of post-processing." This is crucial for someone like David who needs cost-effective machining for production runs with high accuracy.

What are the real pros and cons of using Forming Milling?

Thinking about using forming milling for your next project? It’s smart to weigh the good against the not-so-good. Knowing both sides helps you make an informed decision.

Key advantages of forming milling include high repeatability, excellent surface finish, and efficiency for complex shapes. However, challenges involve higher initial tooling costs and less design flexibility once a cutter is made, as changes require a new tool.

Like any manufacturing process, forming milling has its sweet spots and its limitations. Let's lay them out clearly.

The Upsides: Why Choose Forming Milling?

There are strong reasons why this technique is valued:

- Exceptional Consistency and Repeatability: Once that custom cutter is made and set up correctly, it will produce the same profile part after part. This is fantastic for quality control and interchangeability5, a big plus for someone like David who needs reliable parts.

- Reduced Cycle Times for Complex Profiles: Imagine trying to create a gear tooth shape with a standard end mill. It would take many precise movements and potentially multiple tool changes. A form cutter for gears does it in a much shorter time, often in a single pass per tooth space. This efficiency is a direct cost saving in production.

- Superior Surface Finish: Because the entire profile is cut simultaneously by a sharp, purpose-built edge, the surface finish is often very good, sometimes eliminating the need for secondary finishing operations.

- Capability for Intricate Geometries: It can create complex contours, grooves, and shapes that would be very difficult, time-consuming, or even impossible to achieve economically with standard milling tools in a single setup.

The Downsides: What to Watch Out For

It's not all smooth sailing; there are considerations:

- Initial Tooling Cost and Lead Time: This is probably the biggest hurdle. Custom form cutters are not off-the-shelf items. They need to be designed and manufactured, which means a higher upfront cost and a longer lead time compared to buying a standard mill. This can be a factor for prototypes or very small runs.

- Lack of Flexibility: The cutter is designed for one specific profile. If your design changes even slightly, you'll likely need a new cutter or significant modifications to the existing one. This isn't ideal for iterative design processes.

- Setup Sensitivity: Precisely aligning a custom form cutter can be more critical and time-consuming than setting up a standard tool. Any misalignment can lead to incorrect profiles.

- Chip Evacuation: For deep forms or certain materials, chip evacuation can sometimes be a challenge, potentially affecting surface finish or tool life if not managed properly with coolant and cutting parameters.

In my experience, the decision often comes down to volume and complexity. For high-volume production of a stable, complex design, the benefits usually outweigh the initial tooling investment.

Can you use Forming Milling on any material you want?

Got a specific material in mind for your part? You might be wondering if forming milling is a good fit. Material compatibility is definitely a key factor for success.

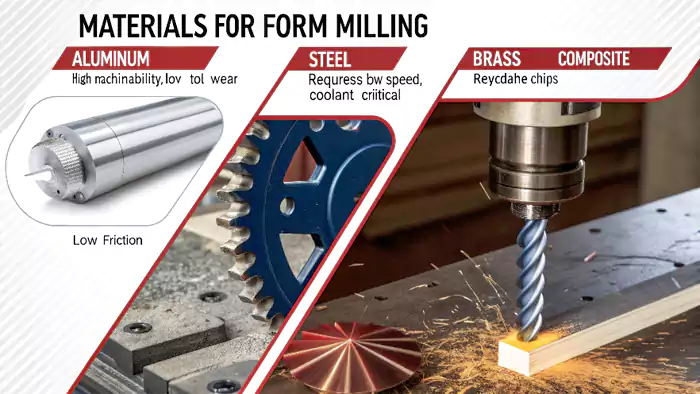

Form milling is suitable for a wide range of materials, including many metals like aluminum, various steels, and brass, as well as some engineering plastics. The material's machinability, hardness, and the intricacy of the desired profile are important considerations.

The choice of material significantly impacts the forming milling process, from cutter design to cutting parameters. Let's look at some common options.

Commonly Form Milled Metals

Most metals that are generally considered machinable can be form milled.

- Aluminum Alloys: These are often a great choice. They are relatively easy to machine, allowing for good cutting speeds and resulting in excellent surface finishes. I've seen fantastic results form milling complex channels in aluminum heatsinks.

- Steels (Carbon, Alloy, Stainless): These are certainly possible, but present more of a challenge. They require more robust cutters (often carbide), slower cutting speeds, and more power from the machine. Stainless steel, in particular, can be tough due to its work-hardening properties. For David, who might be designing industrial automation components, dealing with various steels is common.

- Brass and Bronze: These copper alloys generally machine very well, similar to aluminum, and are good candidates for forming milling, producing fine details and good finishes.

Engineering Plastics

Forming milling isn't just for metals.

- Delrin (POM), Nylon, PEEK: Certain engineering plastics can be successfully form milled. The key here is managing heat, as excessive heat can cause melting or gumming. Sharp tools and appropriate coolants (or air blasts) are important. I recall a project involving custom plastic gears where form milling was the only way to achieve the required tooth profile economically.

Key Material Considerations

Regardless of the specific material, a few factors always come into play:

- Machinability Rating: This gives a general idea of how easily the material can be cut.

- Hardness: Harder materials require harder cutter materials and typically slower cutting speeds.

- Chip Formation: The way a material forms chips can affect the process. Some materials produce long, stringy chips that can be problematic if not managed.

- Coolant/Lubrication: Essential for most forming milling operations to reduce heat, improve tool life, and help flush away chips. The type of coolant will also depend on the material.

So, while forming milling is versatile, you always need to consider the material properties when planning the job and designing the cutter.

What different kinds of Form Milling cutters are out there?

So, you're thinking about specifying a forming milling operation. But what about the actual tool? Understanding the types of form milling cutters can help you communicate your needs effectively.

Form milling cutters are primarily categorized by the shape they produce (e.g., concave, convex, gear tooth) and their physical construction (solid HSS/carbide or inserted tooth). The specific profile needed for the part directly dictates the cutter's design.

The world of form milling cutters is quite specialized, as each tool is essentially a custom solution. However, we can group them into a few general categories.

Solid vs. Inserted Tooth Construction

This is a fundamental distinction:

- Solid Form Cutters: These are made from a single piece of tool material, usually High-Speed Steel (HSS) or solid carbide. The entire profile is ground into this solid piece. They are common for smaller profiles or when extreme precision is needed. Sharpening typically involves regrinding the cutting face, maintaining the profile. I've used many solid HSS form cutters for creating o-ring grooves and custom radii.

- Inserted Tooth Form Cutters: For larger profiles or high-wear applications, cutters with replaceable inserts are often more economical. The main body of the cutter holds one or more inserts that are precision-ground to the required profile. When an insert dulls, it can be replaced or re-sharpened without affecting the cutter body. This can save costs in the long run, especially with expensive carbide inserts.

Classification by Profile Type

Beyond construction, cutters are often named by the type of feature they create:

-

Concave Milling Cutters

These cutters have a curved cutting edge that is convex. They are used to produce a convex radius or a semi-circular convex profile on the workpiece. Think of milling a perfectly rounded edge along a bar.

-

Convex Milling Cutters

Conversely, these have a concave cutting edge (curved inward). They are used to mill a concave semi-circular groove or a concave radius into the workpiece.

-

Gear Cutters (Involute Gear Cutters)

A very common application of form milling is for cutting gear teeth. These specialized form cutters are designed to produce the specific involute profile required for gear teeth. There's a different cutter for each module/pitch and number of teeth range.

-

Spline Milling Cutters

Similar to gear cutters, these are used to mill splines on shafts.

-

Thread Milling Cutters

While sometimes considered a separate category, thread milling is essentially a form milling process where the cutter has the profile of the thread. This offers more control and flexibility than tapping for certain applications.

The specific design, including the number of teeth, rake angles, and relief angles on the cutter, will be carefully engineered based on the material being cut and the desired finish. It’s this level of specialization that makes form milling so effective for its niche.

Conclusion

Forming milling is a powerful CNC technique. It excels at creating specific, complex profiles with high repeatability and efficiency, though initial tooling costs and inflexibility are key considerations.

Footnotes:

-

Learn about the process of creating custom-ground tools and how they enhance precision in milling operations. ↩

-

Explore the benefits of HSS in milling to understand why it's a preferred choice for custom cutters. ↩

-

Learn about feed rate to optimize your CNC machining processes and improve efficiency in your projects. ↩

-

Discover the importance of spindle speed in CNC machining for achieving better results and precision. ↩

-

Exploring interchangeability can reveal its advantages in efficiency and cost-effectiveness in production. ↩