Last Updated: 2025-10-21 09:48:02 Tuesday

Need a cylinder head machined but worried about precision? Incorrect machining leads to poor engine performance, leaks, or even catastrophic failure - a costly risk we've seen too many shops face.

Cylinder head machining involves multiple precise CNC operations like surfacing, chamber shaping, valve seat/guide work, and porting to meet tight tolerances for optimal engine function and durability.

At Allied Metal, we've processed over 500 cylinder heads across automotive, marine, and performance applications. Components like cylinder heads are where precision separates amateur work from professional CNC machining customization. For engineers and shop owners, understanding these manufacturing intricacies is crucial for project success. My core insight from decades in precision manufacturing: the key to cylinder head machining is precision - valve seats, bores, combustion chambers and more require tight tolerances. This isn't just about making a part that fits; it's about making a part that performs under extreme conditions. Because cylinder heads deal with heat, pressure and complex airflow, using advanced CNC machining ensures consistency in every detail and superior performance.

What Key Machining Operations Are Performed on Cylinder Heads?

A cylinder head is more than just a block of metal. What specific, intricate machining steps are needed to transform it into a high-performing engine component?

Cylinder head machining includes deck surfacing (face milling), combustion chamber shaping, precision machining of valve guides and seats, port contouring (often 5-axis CNC), and drilling/tapping various holes.

Diving Deeper into Cylinder Head Machining Steps

Manufacturing Case:

We recently processed a batch of aluminum V8 heads for a marine engine manufacturer. Initial measurements showed deck warpage averaging 0.15mm - beyond acceptable limits. Using our precision face milling process, we restored flatness to within 0.025mm across the entire deck surface. The valve guide bores were honed to 8.002mm ±0.003mm with a surface finish of Ra 0.4μm, ensuring perfect valve stem clearance for both intake and exhaust applications.

Machining a cylinder head is a multi-stage process that demands extreme accuracy at every step. Each feature plays a critical role in the engine's performance, efficiency, and longevity.

Here are the primary machining operations involved:

-

Deck Surfacing1 (Face Milling):

- The "deck" is the critical flat surface that mates with the engine block. This surface must be perfectly flat to ensure a proper seal with the head gasket. We typically achieve surface flatness within 0.025mm using specialized face milling operations.

-

Combustion Chamber Machining:

- The shape and volume of the combustion chamber are crucial for an engine's compression ratio. CNC machining precisely shapes these chambers according to design specifications, often involving complex 3D contouring while maintaining volume consistency within ±0.5cc across all chambers.

-

Valve Guide Installation and Machining:

- Valve guides must be perfectly concentric with the valve seats and have precise internal diameter for proper valve operation. This involves drilling, reaming, and honing the bores for the guides. We typically maintain bore straightness within 0.01mm over the guide length.

-

- Valve seats are critical sealing surfaces. They must be machined to precise angles (typically 45° with 15°-60° top and bottom cuts) and concentricity with the valve guides within 0.025mm to ensure perfect combustion sealing.

-

Porting (Intake and Exhaust Ports):

- CNC porting uses multi-axis milling (often 5-axis) to precisely shape these ports for optimal airflow. Properly executed CNC porting can increase airflow by 15-25% while maintaining port-to-port consistency within 2%.

-

Drilling and Tapping:

- Numerous holes need to be drilled and tapped for spark plugs, manifold bolts, and coolant passages. These must be accurately positioned with positional tolerances typically within ±0.1mm.

-

Spring Seat and Valve Stem Tip Machining:

- Surfaces for valve springs and valve stem tips require precise machining to ensure correct valvetrain geometry, typically maintaining height tolerances within ±0.05mm.

Each of these operations relies heavily on advanced CNC technology to achieve the consistency and tight tolerances demanded by modern engines in our precision machining services.

How Is the Machining of Cylinders (Bores) Typically Handled?

Cylinder heads have critical bores, like valve guides. How are these cylindrical features machined to ensure the necessary precision for engine performance and longevity?

Bores in cylinder heads, such as valve guides, are precisely machined using operations like drilling, reaming, and honing for accurate diameter, straightness, and surface finish crucial for valve operation.

Diving Deeper into Machining Bores in Cylinder Heads

When we talk about "cylinders" in the context of a cylinder head, we are primarily referring to the precision bores that are integral to its function, most notably the valve guides3. While the main engine cylinder bores are in the engine block, the cylinder head houses these critical passages for the intake and exhaust valves.

The machining of these bores within the cylinder head involves several meticulous steps:

-

Initial Hole Creation (Drilling/Casting):

- In cast cylinder heads4 (the most common type), these holes are formed during casting but require significant machining to achieve final precision. For billet heads, we start with precision drilling operations.

-

Precision Sizing and Straightening (Reaming/Boring):

- Reaming: After drilling, reaming brings the bore to precise diameter and improves straightness and roundness. We typically hold diameter tolerances of ±0.005mm during this operation.

- Precision Boring: For higher accuracy, boring using single-point cutting tools on CNC machines allows fine control over diameter and concentricity.

-

Valve Guide Installation (if separate guides are used):

- Many heads use replaceable valve guides pressed into precisely machined bores. After installation, the internal diameter of the guide often needs final-sizing.

-

Final Sizing and Surface Finish (Honing/Fine Reaming):

- Honing: This process uses abrasive stones to produce precise diameter, excellent roundness, straightness, and specific cross-hatch surface patterns that help retain oil. We typically achieve surface finishes of Ra 0.4-0.8μm for optimal lubrication.

- Fine Reaming: Special reamers can achieve tight tolerances and good surface finishes for high-volume production.

Expert Insight: In our custom machining services, we've found that maintaining valve guide bore straightness within 0.01mm over the guide length reduces valve stem wear by up to 40% compared to industry standard tolerances.

What Factors Influence the Cost of Machining a Cylinder Head?

Cylinder head machining is complex. What drives the price? Understanding these factors helps in budgeting and making informed decisions for your engine projects.

Cost depends on head complexity (valves, ports), material (aluminum vs. iron), extent of work (resurface vs. full porting/custom work), required tolerances, quantity, and CNC programming/machine time.

Diving Deeper into Cost Drivers for Cylinder Head Machining

Manufacturing Reality Check:

A recent project highlights cost variables perfectly: A basic cast iron 4-cylinder head resurface might cost $120-180, while a full performance build on an aluminum V8 head with CNC porting, bronze guides, and multi-angle valve jobs can reach $800-1,200. The difference lies in machine time (2 hours vs. 12+ hours) and specialized tooling requirements.

The cost to machine a cylinder head varies significantly based on these key factors:

-

Complexity of the Cylinder Head Design:

- Number of Valves per Cylinder: A 4-valve head requires more machining time than a 2-valve design.

- Overhead Cam (OHC) vs. Pushrod (OHV): OHC designs have more intricate machining for camshaft bearings and mounts.

- Integrated Features: Direct injection ports, complex coolant passages, or variable valve timing components add machining complexity.

-

Material of the Cylinder Head:

- Aluminum Alloys: Generally faster to machine but may require more careful handling to prevent distortion.

- Cast Iron: Harder on cutting tools, requiring slower machining speeds and more frequent tool changes.

-

Extent and Type of Machining Required:

- Basic Resurfacing: Relatively straightforward and less expensive.

- Valve Job: Precision machining of valve seats and guides with multiple angles.

- CNC Porting5: Highly specialized and time-consuming, significantly adding to cost but delivering substantial performance gains.

- Combustion Chamber Modification: Custom shaping requires precise CNC work.

- Repairs: Welding and remachining cracked or damaged areas adds considerable cost.

-

Tolerances and Surface Finish Specifications:

- Tighter tolerances and finer surface finishes require more careful setups, slower machining parameters, advanced tooling, and rigorous inspection.

-

Quantity (One-Off vs. Production):

- Single custom heads have higher per-unit setup and programming costs compared to production batches.

-

CNC Programming and Machine Time:

- Complex 3D porting requires extensive CAM programming. Time on 5-axis CNC machines is a direct cost factor in our CNC machining customization services.

What Is the Overall Manufacturing Process for a New Cylinder Head, Including Machining?

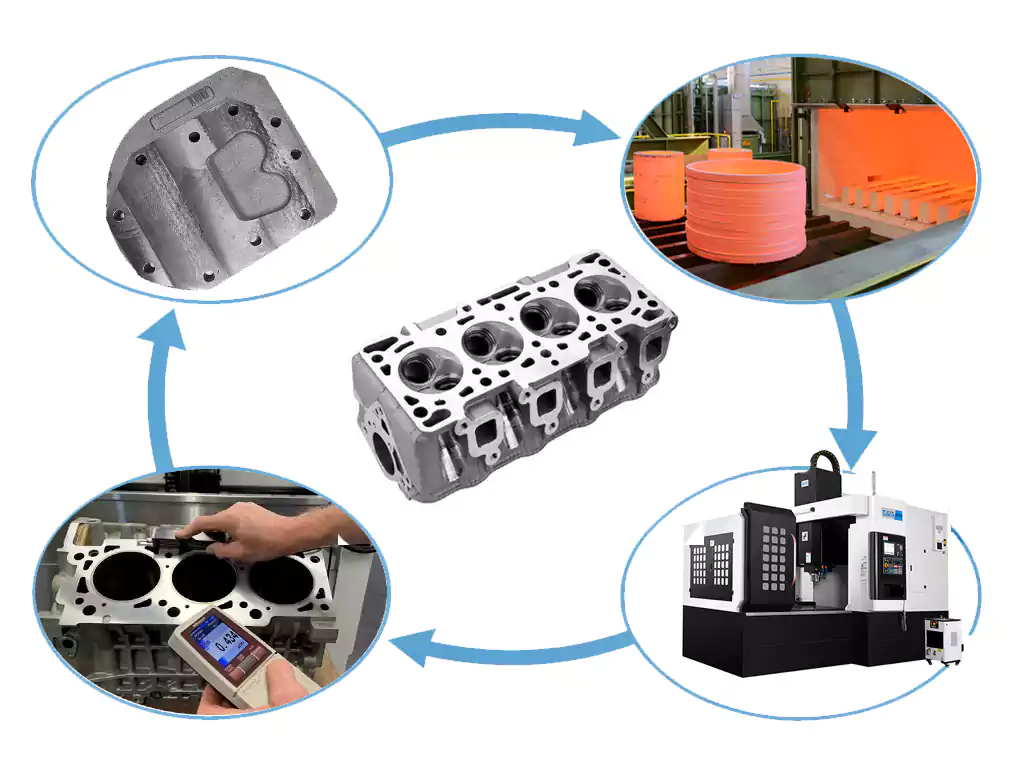

Beyond just machining, what's the complete journey for a new cylinder head? Understanding the full manufacturing path provides context for the critical machining stages.

A new cylinder head typically starts with casting (or billet for custom), followed by heat treatment, then multiple CNC machining stages (decking, chambers, seats, guides, ports), cleaning, and rigorous inspection.

Diving Deeper into the Full Production Cycle

The creation of a new cylinder head, especially for modern high-performance engines, is a sophisticated process involving several distinct stages:

-

Design and Engineering:

- Begins with detailed CAD design, incorporating specifications for port design, combustion chamber shape, and thermal analysis.

-

Material Preparation & Initial Forming (Casting or Billet):

- Casting: Most production heads are cast using aluminum or iron alloys.

- Billet: For high-performance applications, heads can be machined from solid aluminum billet - more expensive but offering maximum design flexibility.

-

- Aluminum heads often undergo heat treatment (e.g., T6) to achieve desired mechanical properties for withstanding heat and pressure.

-

Initial Machining / Qualifying:

- Raw casting or billet is qualified - key surfaces are machined to establish accurate datums for subsequent operations.

-

Core CNC Machining Operations:

- This is where precision work happens:

- Deck surfacing (face milling)

- Combustion chamber machining

- Machining for valve guides and valve seats

- CNC porting of intake and exhaust passages

- Drilling and tapping all necessary holes

- This is where precision work happens:

-

Deburring and Cleaning:

- All sharp edges and burrs are removed. The head is thoroughly cleaned to remove contaminants.

-

Inspection and Quality Control:

- Rigorous inspection using CMMs, bore gauges, and surface profilometers ensures all specifications are met.

-

Assembly (Optional at this stage):

- Valve guides, valve seats, and core plugs are installed.

This comprehensive process, with precision CNC machining at its heart, ensures the cylinder head will perform reliably under demanding conditions in our machining services.

What Types of CNC Machines Are Typically Used to Mill Cylinder Heads?

Cylinder heads have complex shapes and require high precision. What specific CNC machinery is needed to perform these demanding milling and machining operations effectively?

Multi-axis CNC Machining Centers (often 5-axis Vertical or Horizontal) are essential for milling cylinder heads, especially for porting and complex combustion chambers. Specialized valve seat/guide machines are also used.

Diving Deeper into Machinery for Cylinder Head Work

Equipment Expertise:

In our facility, we run both 5-axis vertical machining centers for complex port work and dedicated valve seat machines for high-precision seat cutting. The 5-axis machines allow us to maintain tool perpendicularity to complex port surfaces, while specialized seat machines ensure valve seat concentricity within 0.015mm - critical for compression sealing.

Machining cylinder heads to required precision demands advanced CNC machinery:

-

Multi-Axis CNC Machining Centers:

- 5-Axis CNC Machining Centers: Essential for complex cylinder head work. Capable of moving the cutting tool or workpiece along five different axes simultaneously, crucial for:

- Porting: Machining intricate, curved intake and exhaust ports from optimal angles.

- Combustion Chamber Contouring: Creating complex, non-symmetrical chamber designs.

- Reduced Setups: Often machines most features in a single setup, improving accuracy and reducing cycle time.

- 5-Axis CNC Machining Centers: Essential for complex cylinder head work. Capable of moving the cutting tool or workpiece along five different axes simultaneously, crucial for:

-

Specialized Valve Seat and Guide Machines:

- Dedicated machines (like Serdi or Sunnen equipment) designed for extreme accuracy in cutting valve seat angles and sizing valve guides.

-

CNC Surfacing Machines (Mills):

- For deck surfacing, specialized machines designed for flatness and fine finishes.

-

Coordinate Measuring Machines (CMMs):

- Essential for quality control to verify all critical dimensions and geometric tolerances meet specifications.

For professional CNC machining customization, having access to high-quality multi-axis CNC machining centers is fundamental to tackling complex components like cylinder heads.

Conclusion

Precision CNC machining is vital for cylinder heads, ensuring tight tolerances for chambers, ports, and valve components. This guarantees engine performance, efficiency, and overall reliability. Whether you need basic resurfacing or full custom CNC porting, understanding these processes helps ensure you get the quality results your engine project demands from your machining services provider.

-

Discover why Deck Surfacing is essential for a proper seal in engine assembly, impacting overall engine efficiency and performance. ↩

-

Learn about the techniques in Valve Seat Machining to appreciate its importance in achieving a perfect seal and efficient combustion. ↩

-

Understanding valve guides is crucial for engine performance, as they ensure proper valve operation and longevity. Explore this link to learn more. ↩

-

Learn more about precision investment casting. ↩

-

Learn how CNC porting enhances airflow and engine performance, making it a crucial aspect of cylinder head machining. ↩