Carbon Fiber Processing Guide: Machining, Molding & Applications

- February 11, 2025

- Tony

- Last updated October 21, 2025 By Lucy

Carbon fiber processing plays an increasingly important role in modern manufacturing. From aerospace to automotive manufacturing, carbon fiber processing technology continues to innovate, providing companies with lightweight, high-performance solutions.

1. What is Carbon Fiber?

What is Carbon Fiber?

Carbon fiber is a material consisting of carbon atoms arranged in a high-strength manner to form a fibrous structure, which is widely used in a number of fields due to its light weight, high strength and high heat resistance.

Compared with traditional metal materials, carbon fiber not only has a higher strength-to-weight ratio, but also has better corrosion resistance and electrical conductivity.

Properties of Carbon Fiber

- Strength and lightweight:

The strength of carbon fiber material is several times that of steel, but its density is much lower than steel’s, so it has excellent lightweight advantages. - High Temperature & Corrosion Resistance:

Carbon fiber processed parts are able to maintain structural stability at high temperatures and are highly resistant to chemicals, making them excellent in harsh environments. - Electrical Conductivity:

As we know, carbon fiber has good electrical conductivity and is widely used in electronics. - Low coefficient of thermal expansion:

Carbon fiber has a very low coefficient of thermal expansion, which means it has excellent dimensional stability during temperature changes, making it suitable for use in precision instruments and high-precision equipment. - High designability:

This material can be optimized for a wide range of properties through different weaving methods and composite designs to meet the needs of different application scenarios.

It also has good fatigue resistance and high modulus properties, making it ideal for high-performance applications. Despite the high cost of carbon fiber machined parts, it has a very promising future in high-end applications.

2. Industry Applications for Carbon Fiber Machined Parts

Carbon fiber processing is not only widely used in high-end fields such as aerospace and automotive manufacturing, but also demonstrates its excellent performance in many industries such as sporting goods and medical devices.

Aerospace

Due to its high strength and light weight, carbon fiber has become an ideal material for structural parts of aircraft (e.g. wings, fuselage, etc.). Through precise carbon fiber processing techniques, manufacturers can create extremely strong components while maximizing weight reduction and flight efficiency.

Automotive Manufacturing

As the need for environmental protection and energy efficiency increases, carbon fiber materials are being used in a wide range of high-performance automobiles. Carbon fiber parts such as body frames, interiors, and engine components are processed to not only improve the vehicle’s power performance, but also enhance durability.

Sporting Goods

In high-end sporting equipment, carbon fiber’s light weight and strength make it an ideal choice. From golf clubs to bicycle frames, carbon fiber processing technology helps improve the performance and durability of sports equipment.

Medical Equipment

Carbon fiber’s biocompatibility and strength make it widely used in medical devices as well, such as prosthetics and orthopedic implants. Finely processed carbon fiber parts can provide lightweight, robust solutions that improve patients’ quality of life.

3. Carbon Fiber Processing Methods

Methods of machining carbon fiber vary according to needs, and different machining methods offer their own advantages, often depending on the complexity of the end product and the scale of production.

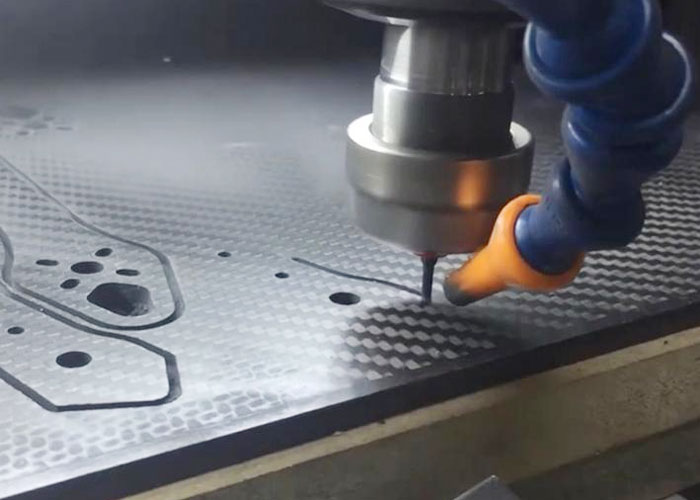

CNC Machining

CNC machining (CNC) is one of the most common precision manufacturing methods used in carbon fiber processing. With CNC machines, complex carbon fiber parts can be precisely cut and shaped.

When performing CNC machining, it is important to choose the right cutting tools and parameters to avoid heat buildup and material damage.

Hand lay-up

Ideal for small quantities or customized carbon fiber parts. The hand lay-up technique allows layers of carbon fiber cloth to be laid in the mold layer by layer, increasing the strength and toughness of the material.

While this method is labor intensive, it offers unmatched flexibility for parts with complex shapes and unique needs.

3D Printing

As technology advances, carbon fiber 3D printing is beginning to be used in manufacturing. By combining carbon fiber-reinforced materials with 3D printing technology, manufacturers are able to produce complex carbon fiber parts quickly and accurately, making them particularly well-suited for prototyping and low-volume production.

Molding and shaping

Molding technology is an effective way to mass produce carbon fiber parts. High-strength carbon fiber composite parts can be produced using resin transfer molding (RTM) or compression molding techniques.

These techniques are particularly well suited for mass production and can ensure the strength and consistency of parts.

4. Challenges and Solutions in Carbon Fiber Processing

Despite the many advantages of carbon fiber, processing this material presents several challenges. Identifying these obstacles and implementing suitable solutions is essential for maintaining processing quality and boosting productivity.

Heat Buildup and Tool Wear During Cutting

Due to its high hardness, carbon fiber tends to cause tool wear and excessive heat buildup during machining. To mitigate these issues, selecting the correct tool material, optimizing machining speeds, and applying effective cooling methods are crucial.

Carbon Fiber Dust and Safety Concerns

The cutting process generates significant amounts of carbon fiber dust, which can compromise air quality and pose health risks to operators. Proper ventilation and protective measures must be in place to ensure safety during processing.

Delamination and Cracking of Carbon Fiber

The interlaminar bonds of carbon fiber composites are relatively weak, making them susceptible to delamination and cracking during machining. This risk can be minimized by adjusting processing techniques and refining cutting tool choices and parameters.

5. Future Trends in Carbon Fiber Processing

As technology advances, carbon fiber processing technology is also evolving. From more efficient processing equipment to smarter production processes, the future of carbon fiber processing will be more precise and efficient, and develop in the direction of environmental protection and sustainability.

Technological Innovations

New generations of CNC technology, laser cutting and ultrasonic processing will make carbon fiber processing more efficient and precise. In the future, these technologies may be combined with AI and automation systems for smarter production.

Environmental protection and sustainability

With the widespread use of carbon fiber materials, the demand for environmental protection and sustainability is increasing. In the future, recycling and reusing carbon fiber materials will become an important direction for the industry.

Case Study: Manufacturing a Lightweight Performance Drone Frame

Let’s look at a project we completed for a client developing a high-performance aerial drone.

The Challenge: A client specializing in industrial inspection drones needed a new frame that was significantly lighter than their previous aluminum design but strong enough to carry heavy sensor payloads and withstand demanding flight conditions. Key requirements included complex mounting points for electronics, high rigidity to prevent vibration, and a very aggressive weight target.

Key Part Specifications:

- Part Name: UAV Main Frame Structure

- Material: Prepreg Carbon Fiber (T700 weave with high-temp epoxy resin)

- Manufacturing Processes:

- CNC Machined Aluminum Mold

- Multi-part Prepreg Layup

- Autoclave Curing (at 6 Bar pressure, 125°C)

- 5-Axis CNC Trimming & Drilling

- Critical Tolerances:

- Mounting Hole Positions: ±0.05 mm (True Position)

- Overall Frame Flatness: 0.2 mm

- Surface Finish: Matte Clear Coat (non-reflective for sensor mounting)

- Target Weight Reduction: > 40% compared to previous aluminum frame

Our Manufacturing Approach

This project required a combination of techniques to achieve the desired outcome:

1. Mold Creation: We first CNC machined high-precision aluminum molds based on the client’s complex 3D CAD model. The mold surface was polished to ensure a smooth finish on the final part.

2. Layup: Skilled technicians carefully laid multiple layers of prepreg carbon fiber fabric into the molds, paying close attention to fiber orientation to maximize strength and stiffness in critical areas.

3. Curing: The laid-up parts were vacuum bagged and cured under high pressure and temperature in our autoclave. This process consolidates the layers and ensures a void-free, high-strength laminate.

4. Trimming & Drilling: After demolding, the cured frame components were precisely trimmed to their final net shape using our 5-axis CNC router. Critical mounting holes were also drilled with extreme positional accuracy.

The Value Delivered

Our multi-step carbon fiber processing approach yielded significant benefits for the client:

- Achieved Weight Target: The final carbon fiber frame weighed 45% less than the original aluminum design, allowing for longer flight times and heavier payloads.

- Increased Rigidity: The specific layup schedule resulted in a frame with 30% higher stiffness, reducing vibrations and improving sensor data quality.

- Met Tight Tolerances: The combination of precision molding and 5-axis CNC trimming ensured all mounting points were within the required ±0.05 mm tolerance, simplifying final assembly.

- Accelerated Development: Delivering the functional prototypes within 4 weeks allowed the client to proceed quickly with flight testing and meet their market launch window.

This case clearly demonstrates how selecting the right carbon fiber processing techniques, combined with precision execution, can deliver substantial performance improvements for demanding applications.

6. Conclusion

As an advanced material, carbon fiber plays an important role in the application of various industries. With the continuous development of processing technology, the advantages of carbon fiber will be more widely used. Whether in aerospace, automotive manufacturing, or medical devices, carbon fiber processing will lead to more efficient and innovative solutions.

Choosing the right carbon fiber processing technology and partner can help companies improve product quality, reduce costs, and gain a competitive advantage in the marketplace.