Editor’s Note: Last modified on November 10, 2025, by Lucy

The Custom Metal Parts Handbook: A 20-Year Machinist’s Guide to CNC Success

Custom CNC machining metal parts is the single most reliable way to create high-performance, complex components with the highest possible precision. Success is defined by three factors: choosing the right alloy, mastering the multi-axis setup (fixturing), and controlling the thermal stress during the cut.

After decades running the floor, I’ve seen every mistake in the book. This guide isn’t about selling you a machine; it’s about giving you the expert blueprint for successful metal parts sourcing. Your job is to design it right; our job is to cut it right. Here’s what you need to know to make the process efficient and risk-free.

Material Selection:

Every custom metal part starts with a material callout. Don’t just pick something because it’s cheap or familiar. The material dictates every single aspect of our machining strategy, and ultimately, your part’s performance.

Common Metalworking Materials

Name | Characteristics | Melting Point | Density Range | Hardness | Strength | Conductivity | Common Parts |

Aluminum | Lightweight, corrosion-resistant | 660°C | 2.7 g/cm³ | 15-100 HB | 70-700 MPa | 37.7 MS/m | Automotive body panels, medical device frames, aerospace components |

Stainless Steel | Corrosion-resistant, high strength | 1400-1450°C | 7.9 g/cm³ | 100-300 HB | 200-800 MPa | 1.45 MS/m | Medical equipment casings, aerospace parts, machinery components |

Copper | Good conductivity, excellent machinability | 1085°C | 8.96 g/cm³ | 35-150 HB | 210-370 MPa | 58.0 MS/m | Applications in electrical, machinery manufacturing, construction, defense industry, etc. |

Machining Strategy: 3-Axis vs. 5-Axis (The Real Cost)

When we look at your part, the first thing we decide is the machining strategy. This is where your total part cost is decided—not just by machine time, but by setup time and human error.

- 3-Axis Machining: It’s cheap, but it requires multiple setups for a complex part. If your part needs to be cut from 4 or 5 sides, we have to unclamp it, reposition it, and clamp it again. Every time we do that, we introduce tolerance stack-up and human error. Fine for simple boxes, but risky for complex geometry.

- 5-Axis Machining: The initial machine hour rate is higher, but it’s often the lowest total cost. We load the block once, and the machine can rotate the part to access almost every feature. This guarantees datum integrity—all features are relative to the original setup—eliminating errors and delivering highest possible precision.

📌Case Study: Aerospace Mounting Bracket

We recently partnered with an aviation client who needed 200 custom mounting brackets for sensor systems. Their previous supplier had consistent issues with weight targets and vibration resistance.

The Challenge:

- Material: 7075 Aluminum (aircraft-grade)

- Weight requirement: Under 450 grams per bracket

- Vibration testing: Withstand 15G acceleration

- Tolerance: ±0.025mm on critical mounting surfaces

- Timeline: 6-week delivery for first batch

Our Approach:

- Started with 25mm thick 7075-T651 plate

- Used 5-axis simultaneous machining for complex contours

- Implemented stress-relief cycles between roughing and finishing

- Applied micro-finishing (Ra 0.4) on bearing surfaces

- Conducted 100% coordinate measurement machine (CMM) verification

The Outcome:

- Final weight: 428 grams per bracket (under target)

- Vibration testing: Passed 18G without failure

– First-article inspection: 98% dimensional compliance - On-time delivery: All 200 units shipped in 5 weeks

The client saved approximately $12,000 in rework costs and avoided a 3-week project delay. The key was our material knowledge – understanding how 7075 behaves under heavy machining and designing our process around its characteristics.

Common Custom Metal Parts Manufacturing Processes

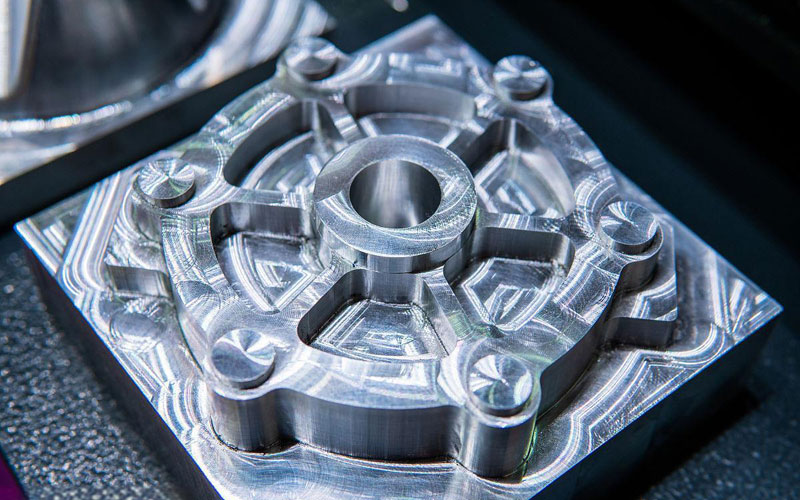

CNC Milling: Your Swiss Army Knife

When you need complex geometries, pockets, or 3D contours, milling is your best friend. We run 3-axis for simpler parts but jump to 4-axis and 5-axis for the really tricky stuff. The beauty of modern milling? We can hold tolerances within 0.01mm all day long.

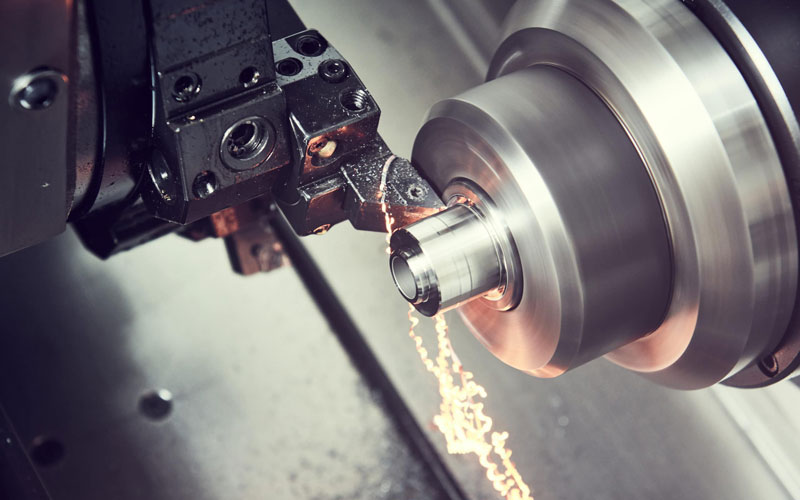

CNC Turning: Round Parts Done Right

Shafts, bushings, fittings – if it’s round, turning is usually your most cost-effective option. We combine turning with live tooling to add cross-holes, slots, and milled features without re-fixturing.

Multi-Axis Machining: Complex Problems Demand Smart Solutions

When parts have features on multiple sides or compound angles, our 5-axis machines become the heroes. Single setup machining means better accuracy and faster turnaround.

Processing Techniques Comparison Table:

Machining Method | Features | Applications | Tolerances | Surface Finish | Cost |

CNC Turning | Ideal for cylindrical parts, high precision, efficient production | Mechanical parts, automotive components | ±0.01 mm | Smooth (Ra 0.8-1.6 µm) | Medium |

CNC Milling | Multi-axis machining for complex geometries | Aerospace, molds, mechanical components | ±0.01 mm | High quality (Ra 0.8-3.2 µm) | Medium |

3D Printing | Layer-by-layer manufacturing, suitable for prototypes and complex parts | Prototypes, complex geometries | ±0.01 mm | Adjustable, rough to smooth | Low to medium |

Rapid Prototyping | Quick production for testing and prototyping | Design iterations, test samples | ±0.01 mm | Variable | Low |

Sheet Metal Fabrication | Suitable for large, thin parts with bending and cutting | Enclosures, brackets, panels | ±0.5 mm | Variable | Low |

Casting | Mass production of complex shapes, suitable for durable parts | Engine housings, mechanical components | ±0.01 mm | Medium (Ra 6.3-12.5 µm) | Low |

What design factors should be considered in metal parts processing?

I’ve seen too many designs that look great on screen but create nightmares in production. Here’s what actually matters:

Wall Thickness – Keep it consistent. Rapid changes in cross-section create stress concentrations and machining challenges. We recommend minimum 1.5mm for aluminum, 2mm for steel.

Internal Radii – Don’t specify sharp internal corners. End mills are round – they can’t cut square corners. Standard tool radii range from 0.5mm to 6mm.

Thread Depth – More isn’t better. For most applications, 1.5 times the diameter gives you full strength. Anything deeper just costs more and risks tool breakage.

Surface Finish – Specify what you need, not what sounds impressive. A 0.8μm Ra finish costs significantly more than 1.6μm. We can help you match finish requirements to actual functional needs.

Controlling Tolerances: A Machining Must

You call out your tolerances on the drawing, but as the machinist, I have to make them happen. This is the difference between a cheap shop and a precision manufacturer.

- The Reality of Temperature: Every metal part heats up during machining, and every metal shrinks as it cools. For ultra-tight tolerances (like ±0.01mm), we often have to implement temperature-controlled environments to ensure the CMM measurement taken at 20°C matches the temperature the part was machined at.

- Secondary Operations: Tolerances on very hard materials (like hardened tool steel) often require grinding after machining. Machining gets us close; grinding gets us there. Always clarify if a tolerance requires a secondary operation.

- Measuring Matters: A shop can’t cut what it can’t measure. Make sure your shop uses high-end, calibrated CMMs and optical comparators for validation, especially on your most critical features.

Final Word: Don't Cut Corners on Custom

If your part is going into a high-stress application—if lives, millions of dollars, or your company’s reputation depend on it—you need a partner who understands the material science and the subtle trade-offs in machining strategy.

Custom metal machining is not cheap, but paying twice because a low-cost shop scrapped your high-value material is even more expensive. Focus on expertise, quality control, and the right strategic machine for your geometry.