The moment a component enters a high-temperature environment—whether in a turbine, an exhaust system, or a chemical reactor—its material becomes the single biggest factor determining reliability. Engineers and procurement managers know this well: choose the wrong alloy, and your part may soften, warp, crack, or fail unexpectedly. Choose the right one, and it will survive thousands of thermal cycles without losing strength or precision.

Heat-resistant alloys exist to solve the exact challenges that destroy ordinary metals: extreme temperatures, oxidation, corrosive atmospheres, thermal fatigue, and mechanical stress—all while staying stable enough for precision CNC-machined applications.

After more than two decades machining these metals, I’ve learned that they behave differently from anything else you put on a CNC machine. They run hot, they harden when you hesitate, and they punish weak fixturing and toolpaths. But with the right material selection and machining approach, they deliver reliability no standard alloy can match. This guide is designed to help engineering teams and procurement professionals choose the right heat-resistant alloy from the start—and avoid costly surprises later.

What Heat-Resistant Alloys Are and Why They Matter

These alloys are metallic materials engineered to retain mechanical strength, dimensional stability, and corrosion resistance at temperatures where common steels and aluminums fail.

Heat-resistant alloys are specifically designed for high-temperature environments found in aerospace turbines, automotive exhaust systems, high-pressure reactors, power generation equipment, and industrial heating systems.

From a machinist’s standpoint, these alloys are built differently: tighter grain structures, higher nickel or cobalt content, and chemistries optimized for oxidation resistance rather than ease of machining. The result is a class of materials that remain strong even when glowing red, resist chemical attack, and maintain their shape under sustained thermal load.

Key High-Temperature Performance Features

- High-temperature strength1 — retains mechanical load at 1500–2000°F

- Oxidation & corrosion resistance2 — protects against scaling, chlorides, and corrosive gases

- Microstructural stability — resists creep and thermal fatigue

- Predictable CNC machining behavior — though challenging, it’s consistent with proper strategy

These are the qualities that make heat-resistant alloys essential for mission-critical parts.

Major Alloy Groups for CNC Machining

Different alloy families address different engineering problems. Understanding their strengths makes material selection far easier.

The primary heat-resistant alloy groups used in CNC machining include nickel-based superalloys, cobalt-based alloys, titanium alloys, heat-resistant stainless steels, and high-temperature tool steels—each offering a unique balance of strength, corrosion resistance, and manufacturability.

Nickel-Based Alloys (Inconel, Hastelloy, Waspaloy)

Nickel superalloys3 are the strongest performers under extreme heat.

- Strength maintained up to 1800–2000°F

- Excellent resistance to oxidation and corrosive gases

- Stable during repeated thermal cycling

Common grades:

- Inconel 718 – turbine rings, hot casings

- Inconel 625 – marine & chemical systems

- Hastelloy X – combustion ducts & chambers

Nickel alloys also present the toughest machining challenges due to heat concentration and rapid work hardening.

Cobalt-Based Alloys (Stellite, Haynes)

When high heat meets abrasive wear, cobalt alloys outperform every other class.

- Exceptional hot hardness

- Extreme wear and erosion resistance

- Ideal for valve seats, pump sleeves, turbine wear inserts

Their downside is severe tool wear if machining parameters are not tightly controlled.

Titanium Alloys (Ti-6Al-4V, Ti-6242)

Titanium provides excellent performance at moderate temperatures with very low density.

- Strength-to-weight ratio unmatched

- Works well up to ~1000°F

- Common in aerospace compressor sections, lightweight thermal structures

Titanium is easier to machine than superalloys, but still requires careful heat management.

Heat-Resistant Stainless Steels (310, 316, 321, 347)

A practical choice for mid-temperature environments.

| Grade | Max Temp | Typical Use |

|---|---|---|

| 310 Stainless | ~2000°F | Furnace components |

| 321 / 347 Stainless | 1500–1650°F | Exhaust systems |

These steels offer affordability and availability while providing solid high-temperature durability.

High-Temperature Tool Steels

Designed for applications involving mechanical shock and high compressive loads.

- Strong hot hardness

- High compressive strength

- Good thermal crack resistance

Ideal for dies, shear blades, and forming tools—not ultra-high-temperature parts.

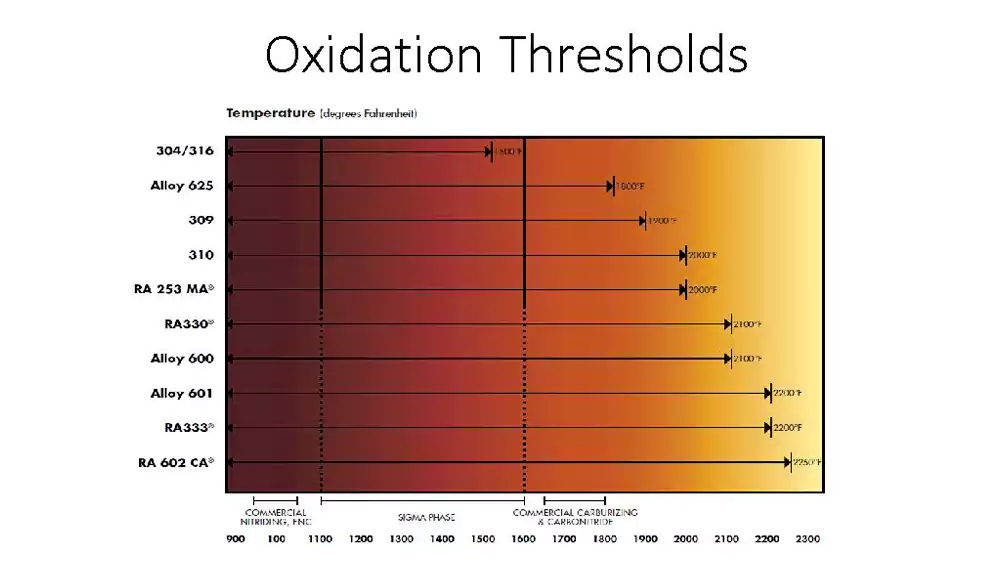

Temperature Performance & Material Selection Guide

Selecting the right alloy begins with knowing its temperature limits and matching those limits to the real-world environment of the part.

Nickel and cobalt superalloys top the charts for temperature capability, while stainless steels and titanium alloys serve mid-range conditions more cost-effectively.

Temperature Ranges by Alloy Family

| Alloy Family | Working Limit | Applications |

|---|---|---|

| Nickel superalloys | 1800–2000°F | Turbines, combustors |

| Cobalt alloys | 1800°F+ | High-wear hot surfaces |

| Heat-resistant stainless | 1500–1800°F | Exhausts, heating units |

| Titanium alloys | ~1000°F | Lightweight structures |

Metals That Survive ~2000°F

Only select alloys remain structurally stable near 2000°F:

- Inconel 718

- Inconel 625

- Hastelloy X4

- Haynes 230

- 310 Stainless (short exposure only)

How to Select the Right Alloy

Correct alloy choice depends on more than just temperature.

Match the Temperature

- <1000°F → stainless or titanium

- 1000–1500°F → heat-resistant stainless / nickel alloys

- 1500–2000°F → nickel or cobalt alloys

Match the Environment

- Chlorides → Inconel 625

- Oxidizing heat → Hastelloy X

- Marine → 625 or 825

Evaluate Mechanical Load

- High force → tool steels

- High heat → nickel alloys

Consider Manufacturing Cost

Superalloys require slower machining and more tool changes.

Verify Certifications

- Aerospace → AMS

- Energy → ASTM / EN

- Chemical → NACE

Selecting the right alloy reduces machining risk and ensures real-world reliability.

CNC Machining Characteristics of Heat-Resistant Alloys

Machining these alloys reveals their true nature: they hold heat, resist cutting, and punish hesitation.

Heat-resistant alloys concentrate heat at the cutting edge, work-harden instantly under light engagement, and cause rapid tool degradation without strict process control.

What Makes Them Difficult to Machine

- Low thermal conductivity

- Immediate surface hardening under low chip load

- High cutting temperatures

- Demanding material removal rates

Best Practices from 20+ Years of Machining

Maintain Strong, Consistent Chip Load

Avoid shallow passes—this creates a hardened shell.

Use High-Pressure Coolant (≥1000 psi)

Prevents chip welding and stabilizes tool temperature.

Use Ceramics for Roughing Superalloys

Allows higher temperatures and fast material removal.

Use Coated Carbide for Finishing5

Needed for tight tolerances and smooth surface finishes.

Keep Fixturing Extremely Rigid

Even slight vibration ruins tool life.

Lower SFM Compared to Steel

Superalloys demand slow, controlled cutting.

Mastery of these techniques turns an impossible job into a predictable process.

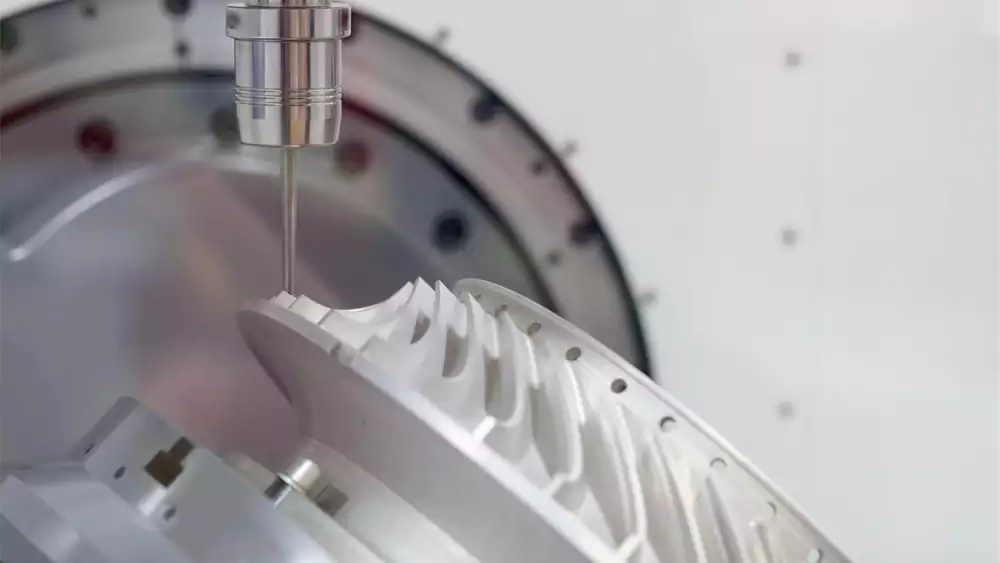

Case Study: Inconel 718 Turbine Support Ring

A European aerospace manufacturer needed a thermal-cycling-resistant turbine support ring. The component required both high mechanical strength and stability at 1750°F.

This project demonstrates the importance of combining the right alloy with the right machining strategy—especially for superalloys like Inconel 718.

Technical Specs

| Parameter | Value |

|---|---|

| Material | Inconel 718 |

| Part Type | Turbine support ring |

| Final Weight | 3.42 kg |

| Max Operating Temp | 1750°F |

| Process | 5-axis milling + CNC turning |

| Flatness | ≤ 0.03 mm |

| Surface Finish | Ra 1.6 μm |

| Tools | Ceramic inserts + carbide end mills |

| Coolant | 1000 psi through-spindle |

Machining Challenge & Solution

Roughing quickly produced surface hardening—common with 718. Switching to ceramic roughing tools at higher SFM, combined with consistent chip load, prevented glazing. Deep features trapped heat, so I programmed controlled cooling pauses to prevent distortion. This preserved the 0.03 mm flatness requirement.

The finished part passed all thermal-cycle and dimensional stability tests.

FAQ

Is Inconel a heat-resistant alloy?

Yes, it’s one of the most widely used nickel-based superalloys.

Which alloy withstands the highest temperature?

Nickel and cobalt superalloys.

What metal can survive 2000°F?

Inconel 625/718, Hastelloy X, Haynes 230, and some stainless grades.

Is 6061 aluminum heat-resistant?

No. It loses most of its strength around 300°F.

Summary

Heat-resistant alloys are the backbone of modern high-temperature engineering. With the right alloy and machining strategy, components can withstand environments that destroy ordinary materials. Each alloy family offers unique strengths—and understanding these differences helps engineers design safer, longer-lasting, and more cost-efficient parts.

-

Understanding high-temperature strength can help you choose the right materials for extreme conditions. ↩

-

Exploring this topic reveals how these properties enhance durability and longevity in harsh environments. ↩

-

Explore the advantages of Nickel superalloys for extreme heat applications, including their strength and resistance properties. ↩

-

Discover why Hastelloy X is a top choice for extreme conditions, enhancing your knowledge of material selection for high-performance applications. ↩

-

Learn about the advantages of coated carbide tools for achieving tight tolerances and superior surface finishes. ↩