Improving CNC Machining Efficiency: 10 Essential Strategies

- December 31, 2024

- Tony

- Last updated on October 28, 2025 by Lucy

After over 20 years in CNC shops, I’ve seen the same pattern: shops working harder instead of smarter. The difference between profitable and struggling often comes down to these ten efficiency strategies. Let me show you how to implement them without breaking the bank.

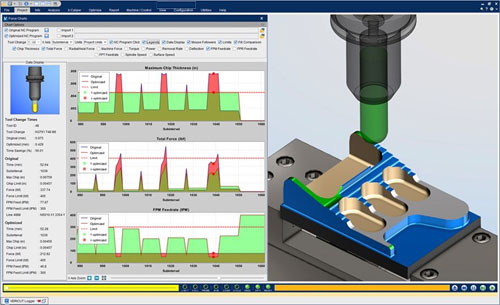

1. Software That Actually Works For You

Stop fighting your CAD/CAM system. The right software should feel like an extension of your brain, not a constant battle.

What to look for:

- Simulation that doesn’t lie: Catch crashes before they happen

- Toolpath optimization: Reduces air cutting by 30-50%

- Post-processors that work: No more manual G-code editing

Reality check: Good software pays for itself in 3-6 months through reduced programming time and fewer crashes.

2. Optimization and Simplification of G-code

G-code is the basic programming language that guides CNC machine tools to perform precise tasks. If G-code is effectively optimized, machining times can be significantly reduced and part accuracy improved. The entire machining process can be simplified by eliminating unnecessary instructions, reducing machine movements and minimizing tool wear.

Advanced programming techniques such as canned cycles and tool path simplification, for example, can further improve CNC machining efficiency. The goal is to refine the G-code so that the machine runs at optimum performance, minimizing downtime and maximizing productivity.

I’ve seen programs with 40% wasted motion. Clean G-code is like a well-organized shop – everything flows smoothly.

Quick wins:

- Eliminate redundant position commands

- Use canned cycles (G81, G83) instead of manual drilling

- Optimize toolpaths to minimize rapid moves

Pro tip: A 15-minute code review can save 2 hours of machine time on complex parts.

Case Study: From 8 Hours to 3.5 Hours on Aluminum Housings

We had a client machining 50 aluminum sensor housings monthly. Their process was bleeding money:

Original Process:

- Cycle time: 8 hours per part

- 4 tool changes with manual positioning

- 35% of time spent on non-cutting moves

- Scrap rate: 12% due to positioning errors

What We Changed:

- Rewrote G-code using advanced canned cycles

- Implemented toolpath optimization in CAM

- Added probe routines for automatic calibration

- Consolidated operations from 8 to 5

Results:

- New cycle time: 3.5 hours (56% reduction)

- Tool changes: 2 (automated)

- Scrap rate: 2% (probe verification)

- Monthly savings: $3,200 in machine time + $800 in material

The client now runs these parts unattended overnight. Sometimes the biggest gains come from working smarter, not faster.

3. Tool Selection - Stop Using the Wrong Tools

Choosing the right tool for the job is critical in CNC machining. Not only does the tool affect the quality of the final product, but it also impacts the efficiency of the machining process. Tool optimization involves selecting the right tool materials, coatings, and geometries to ensure they last longer and provide better performance.

It’s also essential to rationally select the correct tool for each specific operation. For instance, using a high-speed steel (HSS) tool for softer materials, or carbide tools for harder materials, can enhance cutting efficiency and reduce wear. A well-chosen tool helps reduce downtime, increases throughput, and ultimately improves overall machining efficiency.

4. Speeds & Feeds - The Heart of Efficiency

Adjusting the rotational speed and feed rate based on the material and cutting conditions is crucial for achieving optimal CNC machining results. Rotational speed refers to the speed at which the tool rotates, while the feed rate is the rate at which the tool advances through the material.

Optimizing these parameters based on material type and thickness ensures a balance between cutting efficiency and tool life. For example, reducing the feed rate and rotational speed can reduce the risk of tool wear when machining hard metals. On the other hand, increasing these parameters for softer materials can speed up the process without compromising quality.

I still see shops using manufacturer’s recommended settings. Those are starting points, not gospel.

My real-world parameters for 6061 aluminum:

- Roughing: 1800 RPM, 15 IPM, 0.150″ DOC

- Finishing: 2400 RPM, 8 IPM, 0.010″ DOC

- Drilling: 3000 RPM, 5 IPM peck cycle

Key insight: 20% adjustment in feed rate can double tool life or cut cycle time by 30%.

5. Regular Maintenance and Precise Calibration of CNC Machining Equipment

To maintain optimal CNC machining performance, regular maintenance and calibration are crucial. Over time, machine parts can wear, and calibration may drift, impacting precision and efficiency. Routine tasks like cleaning, lubricating, and calibrating help keep the machine accurate and reduce unexpected downtime.

Breakdown maintenance costs 3x more than preventive maintenance. Here’s my weekly checklist:

Daily (5 minutes):

- Check coolant levels and concentration

- Verify lubrication system

- Clean way covers and chips

Weekly (30 minutes):

- Ball screw and guide way inspection

- Spindle runout check

- Backup parameters and programs

6. Operator Skills - Your Most Valuable Asset

Even the best CNC machines and software can fall short without skilled operators. To maximize efficiency, it’s crucial to train employees in the latest CNC techniques. Focused training in programming, troubleshooting, machine setup, and advanced cutting methods can reduce errors and enhance production quality.

A $100,000 machine with a $15/hour untrained operator is a money-losing combination.

What I train my team on:

- G-code reading and editing

- Basic troubleshooting

- Tool wear recognition

- Setup optimization

Result: 25% reduction in setup times and 40% fewer crashed tools.

7. Toolpath Strategy - Think Like the Tool

The design of the CNC machining path directly influences machining speed, tool wear, and part accuracy. An optimized machining path minimizes unnecessary movements and ensures that the tool efficiently covers the material’s surface.

The shortest distance between two points isn’t always the most efficient in CNC.

My approach:

- Roughing: Adaptive clearing saves 30% time vs. conventional

- Finishing: Scallop patterns for complex surfaces

- Holes: Peck drilling with optimized retract heights

8. Integration of Automation Equipment and Systems

Automation is one of the most effective methods for enhancing the efficiency of CNC machining. The integration of automated equipment, such as robotic arms for material loading and unloading, can significantly reduce cycle times and minimize the need for human labor. Automated systems streamline processes, decrease the likelihood of human error, and enable longer, uninterrupted machining cycles.

Incorporating automated tool changers and robotic arms into your system can significantly reduce downtime and accelerate the machining process, especially for high-volume production runs.

9. Coolant Management - The Overlooked Hero

Cutting fluids play a crucial role in the machining process by cooling both the tool and the workpiece, reducing friction, and enhancing the surface finish. However, improper management of cutting fluids can lead to inefficiencies and increased operational costs.

Rationalizing the use of cutting fluids involves selecting the appropriate type and quantity of fluid for each operation, as well as ensuring that the fluid is properly filtered and recycled. Automated systems that monitor and regulate fluid usage can minimize waste, extend tool life, and enhance machining efficiency.

10. Production Scheduling and Management of Machine Downtime

To optimize the efficiency of CNC machining, it is essential to implement effective production scheduling and minimize machine downtime. Scheduling should prioritize high-value orders and maximize machine utilization during operational hours. Additionally, reducing downtime associated with tool changes, maintenance, and setup is crucial for enhancing overall throughput.

Real-time monitoring systems enable the tracking of machine performance, the identification of bottlenecks, and the detection of periods of inactivity. This capability facilitates timely adjustments and enhances resource allocation.

Conclusion

Improving the efficiency of CNC machining involves more than simply selecting high-quality software, optimizing cutting parameters, and implementing automation. It is crucial for manufacturing organizations to concentrate on the ten strategies outlined in this article to reduce costs, enhance yields, and maintain product quality.