Table of Contents:

Cutting CNC Costs: Your Guide to Unit Cost Optimization

- November 21, 2024

- Tony

- Last updated on November 12, 2025, by Lucy

When you’ve been in machining as long as I have, you learn that cost control isn’t about cutting corners—it’s about cutting smarter. Here’s how we drive down unit costs without sacrificing quality.

1. Tooling and Material Selection Optimization

Choose the right tool and material from the start. It sounds simple, but using over-spec’d materials or the wrong end mill burns money fast.

- Match material grades to actual product requirements—don’t over-engineer.

- Optimize cutting paths to reduce cycle time and tool wear.

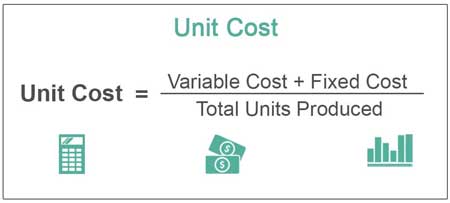

Components of Unit Cost

Unit cost is mainly composed of the following parts:

- Material Cost: It includes the price of materials and their utilization. Waste of materials will directly push up the unit cost.

- Processing costs: the complexity and time required for each process.

- Equipment Costs: Depreciation and maintenance costs of equipment are allocated to each product.

- Labor Costs: The salary of skilled workers and their efficiency.

- Quality Costs: Includes the cost of quality control, scrap and rework.

An in-depth understanding of these components is the basis for developing an optimization strategy.

2. Machining Process Improvement

Time is money. The less time a part spends in the machine, the cheaper it gets.

- Use high-efficiency toolpaths and reduce non-cut time.

- Minimize setups: group similar operations and use modular fixtures.

📌Case Study: Turning a $50 Part into a $18 Part

We were approached by a Medical Device Company to manufacture a complex Aluminum Fixture Block. The initial design was technically sound but incredibly expensive due to inefficient machining.

The Challenge: The original part had 20 deep pockets that were all rectangular, featuring tiny 1.0 mm internal corner radii. Machining these 1.0 mm corners was consuming 45% of the total cycle time using tiny, expensive tools.

Key Specs & The Cost Reduction:

- Part: Aluminum 6061 Fixture Block (150 mm x 100 mm x 30 mm)

- Initial Unit Cost: $50.50 (due to long cycle time and tool changes)

- Critical Tolerance: ±0.02 mm only on the main mounting face.

- Non-Critical Feature: 20 deep pockets with 1.0 mm internal radii.

The Shop-Floor Truth (The DFM Solution):

- Design Change: We recommended changing the internal radii in the 20 pockets from 1.0 mm to 3.0 mm. This radius increase did not affect the part’s functionality.

- Tooling Improvement: The change allowed us to swap from a fragile 2.0 mm end mill to a robust 6.0 mm end mill for the bulk of the pocket milling.

- Speed Increase: Using the larger, stronger tool, we increased the feed rate by 150% and the cutting depth.

- The Result: The total machining time for the block dropped from 35 minutes to just 12 minutes. The new unit cost was $17.90, a massive 64% reduction, simply by changing one non-critical design feature.

The lesson: A small design compromise can lead to huge savings in production.

3. Improve Equipment Efficiency

A well-tuned machine is a profitable machine.

- Regular equipment maintenance: Prevent downtime and rework caused by equipment failure to ensure stable operation.

- Utilize automation technology: Introduce automatic feeding and tool changing systems to improve processing efficiency and reduce labor costs.

4. Mass production and inventory management

Too much stock ties up cash; too little causes delays.

- Adopt just-in-time production to reduce carrying costs.

- Keep optimal inventory levels to avoid rush fees and minimize handling.

5. Optimized design and programming

Design for manufacturability. Sometimes a small tweak to a CAD model can save hours on the floor.

- Simplify geometries where possible.

- Standardize features to use common tools and reduce programming effort.

6. Outsourcing and resource integration

Know what to keep in-house and what to farm out.

- Outsourcing non-core operations: Outsource non-core machining tasks to reduce equipment investment and maintenance costs.

- Supply Chain Resource Integration: Cooperate with upstream and downstream enterprises to share resources and realize scale effect.

7. Strengthen quality control

Catch errors early. A scrapped part costs more than just material—it costs time and capacity.

- Reduce scrap rate: Add automated inspection in each key step to reduce production loss.

- Control rework costs: Improve the accuracy of tolerance control and reduce the extra costs incurred by rework.

Summary

Don’t wait until the design is locked to get a quote. Send us your files during the design phase. A good machinist will look at your part not just for manufacturability, but for cost optimization. We want to give you the cheapest possible part that meets your performance specifications.