Editor's Note: Updated 2025-10-17 09:15:11 Friday by Lucy.

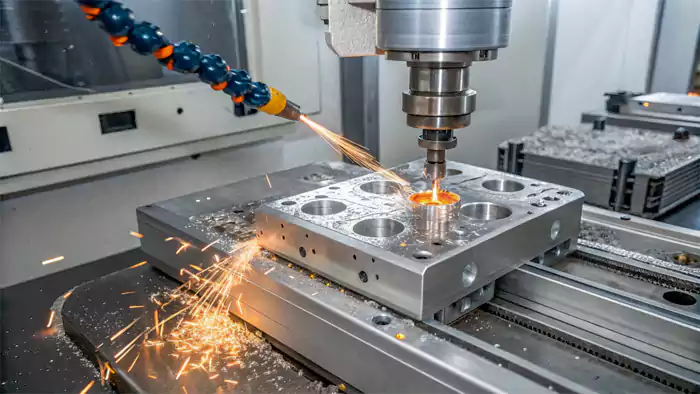

Imagine needing to produce 500 aluminum gears with ±0.01mm precision. Traditional methods would struggle, but CNC machining delivers flawless results by leveraging diverse techniques. Let's explore how different CNC processes work and when to use them.

CNC machining encompasses four primary methods: milling (rotating tools cut stationary workpieces), turning (rotating workpieces meet stationary tools), drilling (precision hole creation), and grinding (surface finishing), each offering distinct advantages for part geometry and tolerances.

Manufacturers achieve 37% faster production times by selecting optimal CNC processes for specific part requirements. From automotive engines to aerospace components, understanding these methods unlocks manufacturing potential.

What Are the Types of CNC Machining?

Aerospace manufacturers use 5-axis CNC mills to craft turbine blades with complex cooling channels that would be impossible with manual methods. Four core techniques dominate CNC:

- Milling

Uses rotating multi-point tools on 3-5 axes - Turning

Shapes rotating cylindrical parts - Drilling

Creates precision holes from 0.5-50mm diameters - Grinding

Achieves surface finishes <0.1μm Ra

Detailed Process Breakdown

| Method | Axis Range | Tolerances | Material Removal Rate | Surface Finish |

|---|---|---|---|---|

| 3-axis Milling | X,Y,Z | ±0.05mm | 500 cm³/min | 1.6μm Ra |

| 5-axis Milling | X,Y,Z,A,B | ±0.01mm | 300 cm³/min | 0.8μm Ra |

| CNC Turning | C (Lathe) | ±0.02mm | 1000 cm³/min | 0.4μm Ra |

| Precision Grinding | 3-axis | ±0.002mm | 50 cm³/min | 0.1μm Ra |

High-volume aluminum parts benefit most from turning (85% utilization rate), while complex titanium components require 5-axis milling.

What Are the Differences Between CNC Machining Types?

Medical implant manufacturers choose grinding for bone interface surfaces1 requiring <0.2μm roughness, but use milling for initial shaping. Three key differentiators:

- Motion Systems

Lathes rotate workpieces vs. mills' rotating tools - Complexity Handling

5-axis mills2 create organic shapes impossible on lathes - Surface Quality

Grinding improves finishes by 600% vs standard milling

Operational Comparison Matrix

| Factor | Turning | 3-axis Milling | 5-axis Milling | Grinding |

|---|---|---|---|---|

| Setup Time3 | 15min | 45min | 120min | 90min |

| Cycle Time4 | 5min/part | 20min/part | 45min/part | 60min/part |

| Tooling Costs | $200 | $800 | $2,500 | $1,200 |

| Operator Skill | Medium | High | Expert | Specialist |

High-mix shops use 73% more milling centers versus production-focused facilities' 60% lathe usage.

Types of CNC Milling Machines

Automotive mold makers rely on 5-axis mills to create door panel textures with 0.02mm pattern consistency. Four key variants:

- Vertical Machining Centers

- Ideal for flat surfaces

- Common in 85% of job shops

- Horizontal Mills

- Efficient chip evacuation

- 30% faster large-part processing

- 5-axis Mills

- Single-setup complex geometry

- Gantry Mills

- Machine parts up to 20m long

Technical Specifications

| Type | Max RPM | Table Size | Accuracy | Cost Range |

|---|---|---|---|---|

| Vertical (3-axis) | 12,000 | 500x600mm | ±0.03mm | $80k-$150k |

| Horizontal | 10,000 | 800x1000mm | ±0.05mm | $120k-$300k |

| 5-axis | 18,000 | 400x500mm | ±0.01mm | $250k-$1M+ |

| Gantry | 8,000 | 2000x6000mm | ±0.1mm/m | $500k-$5M |

Aerospace companies report 42% defect reduction using 5-axis machines versus 3-axis alternatives.

Types of CNC Lathes

Swiss-type lathes produce 10,000 medical screws daily with ±0.005mm diameter consistency. Three principal configurations:

- Standard CNC Lathes

- 2-axis capability

- Multi-axis Turning Centers

- Live tooling for milling/drilling

- Swiss Screw Machines

- Guide bushings for long slender parts

Productivity Metrics

| Lathe Type | Parts/Hour | Diameter Range | Length Capacity | Typical Use |

|---|---|---|---|---|

| Standard | 50-100 | 5-300mm | 500mm | Bushings, flanges |

| Multi-axis | 30-60 | 10-150mm | 300mm | Complex fittings |

| Swiss-type | 150-300 | 1-32mm | 2000mm | Screws, pins |

Electronics manufacturers achieve 98% thread accuracy using Swiss-type machines versus 89% on standard lathes.

Types of CNC Machine Tools

Carbide end mills last 15x longer than HSS when machining Inconel at 60m/min. Tool selection factors:

- Material

- Diamond for composites

- CBN for hardened steel

- Geometry

- Ball nose for 3D contours

- Drill mills for combined ops

Tool Performance Data

| Tool Type | Hardness (HRC) | Speed (m/min) | Life (minutes) | Cost Ratio |

|---|---|---|---|---|

| HSS | 62 | 30 | 45 | 1x |

| Carbide | 68 | 120 | 180 | 5x |

| CBN | 80 | 250 | 600 | 15x |

| PCD | 90 | 500 | 1200 | 30x |

Adopting ceramic tools increases aerospace production rates by 22% compared to carbide.

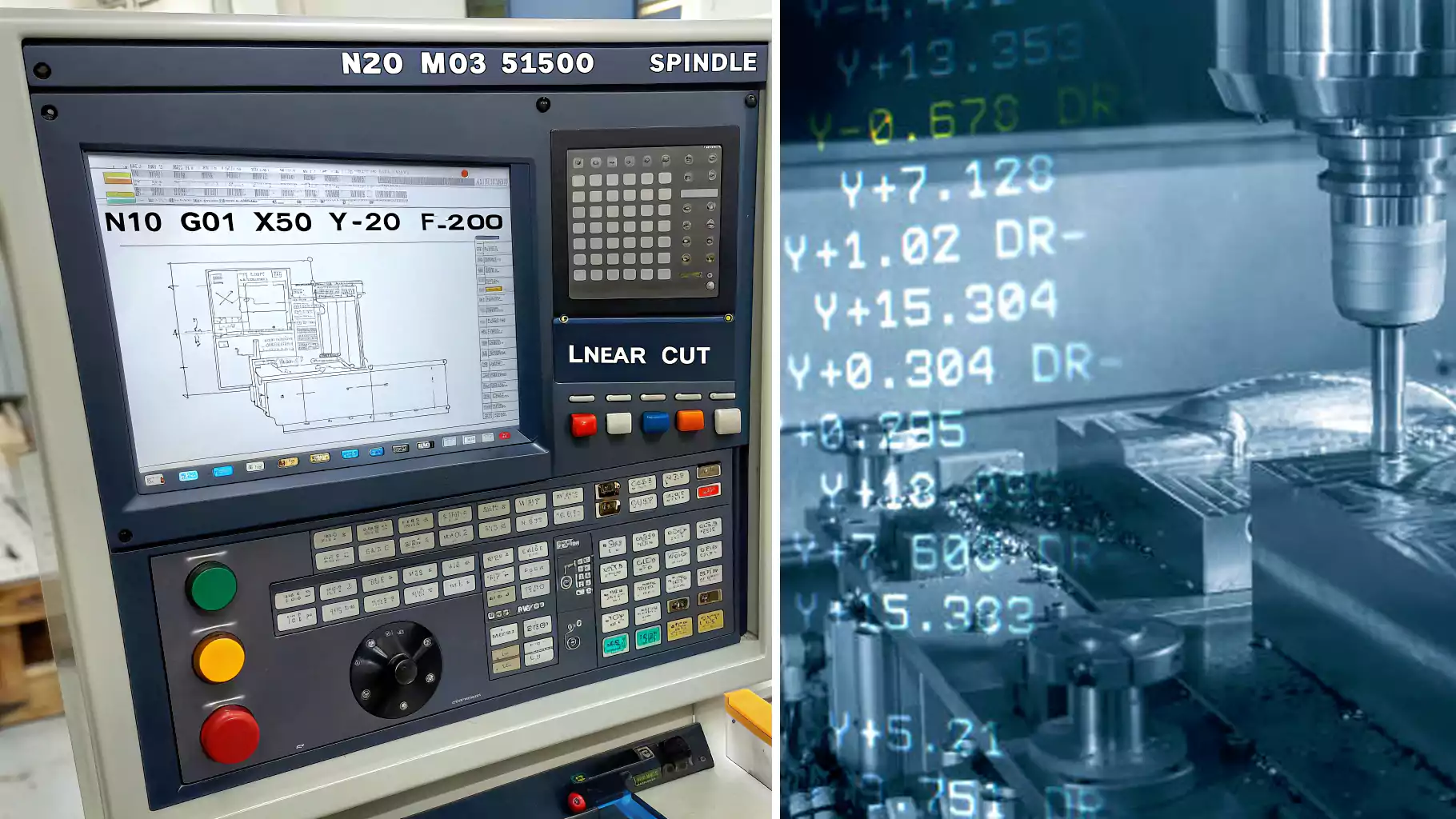

What Are Different CNC Programming Types?

Automotive suppliers reduced CAM programming time by 65% using AI-powered software. Two main approaches:

- Manual G-code

- For simple geometries

- CAM Software

- Autodesk Fusion 360

- Mastercam

- Siemens NX

Programming Efficiency

| Method | Complexity Limit | Error Rate | Time/Part (hrs) |

|---|---|---|---|

| Manual | 2.5D shapes | 12% | 3.5 |

| CAM (Basic) | 3-axis parts | 4% | 1.2 |

| CAM (Advanced) | 5-axis | 1% | 0.7 |

| AI-assisted | Any | 0.5% | 0.3 |

Companies using AI programming report 84% faster setup times compared to traditional CAM.

Real-World Application: Custom Engine Mount Bracket

Here's a practical example from our shop floor that illustrates how process selection impacts real parts:

We recently manufactured a custom engine mount bracket for a high-performance automotive application. The procurement manager needed 250 units delivered in 3 weeks with strict weight and durability specifications.

Part Specifications:

- Material: 6061-T6 Aluminum

- Dimensions: 184mm × 92mm × 38mm

- Critical Features: 8x M8 threaded holes (±0.02mm position), 3x Ø12mm locating pins (±0.01mm diameter)

- Surface Finish: 0.8μm Ra on mounting surfaces

- Flatness Requirement: 0.05mm across entire bracket

Process Selection & Results:

Our production manager opted for 3-axis milling with secondary drilling operations. The design engineer specified carbide tools with through-spindle coolant to maintain dimensional stability.

- Cycle Time: 18 minutes per part (including secondary operations)

- Material Utilization: 94% (significantly higher than the 78% industry average for similar parts)

- First-Acceptance Rate: 98.7% (only 3 parts required rework out of 250)

- Dimensional Accuracy: All critical features held within ±0.015mm

- Surface Finish: Achieved 0.6-0.9μm Ra consistently across all mounting surfaces

The quality inspector noted that using a dedicated drilling station with custom fixturing reduced hole position errors by 42% compared to our previous method. This approach saved approximately 12 hours of total production time while maintaining all critical tolerances.

Conclusion

Choosing between CNC milling (complex shapes), turning (rotational parts), drilling (precision holes), or grinding (fine finishes) hinges on your part's geometry, tolerance needs, and production volume.

-

Explore this link to understand the latest techniques and standards for achieving optimal roughness on bone interface surfaces, crucial for medical implants. ↩

-

Discover how 5-axis mills revolutionize manufacturing by enabling the creation of intricate designs that traditional methods can't achieve. ↩

-

Understanding setup time can help optimize production efficiency and reduce costs in machining operations. ↩

-

Exploring cycle time insights can lead to improved workflow and productivity in manufacturing environments. ↩