Struggling to drill holes accurately and consistently across many parts? Manual layout is slow, and errors can lead to expensive scrap and production delays.

A jig is a custom workholding device that holds a workpiece in a specific position and guides the cutting tool for a particular operation, ensuring accuracy, repeatability, and efficiency.

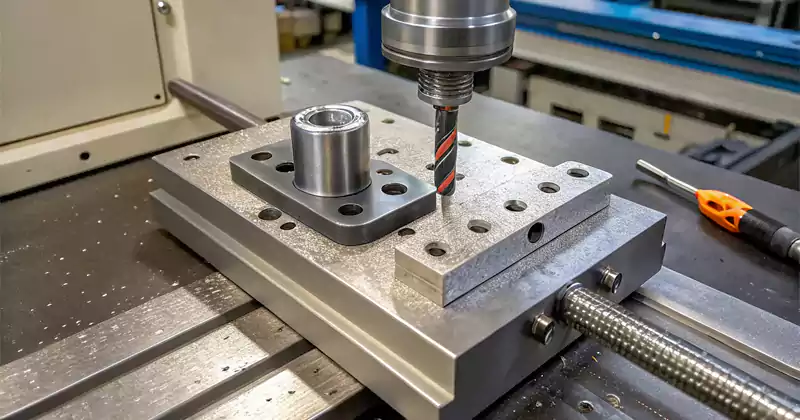

In my line of work at Allied Metal, precision and repeatability are everything. When you're making hundreds or thousands of identical parts, you need a process that is both fast and flawless. This is where well-designed workholding becomes critical. For engineers like David who need consistent quality, understanding tools like jigs is incredibly valuable. In machining, a jig tool is a specialized aid that accurately positions the workpiece and guides the cutting tool—typically a drill, reamer, or boring tool. Its purpose is to guarantee that operations are performed in the exact same spot on every single part. Using a jig ensures precise, repeatable results in tasks like drilling and milling, helping to improve consistency, streamline operations, and boost automation efficiency.

What Is a Jig Tool Used For in Manufacturing?

You know a jig holds a part, but what is its specific job? What tasks in a machine shop benefit most from using a custom-designed jig tool?

A jig is used to securely hold a workpiece while guiding a cutting tool for specific operations like drilling, reaming, or boring, ensuring accurate location and repeatability without manual marking.

Diving Deeper into the Applications of Jigs

The primary use of a jig tool is to make manufacturing processes simpler, faster, and much more accurate, especially for batch production. It essentially removes the need for manual measurement and layout for each individual workpiece. For the engineer, specifying a jig for a production run can be a key step in ensuring quality control.

Here are the main functions and uses of a jig:

Ensuring Accurate Hole Placement

This is the most common application. A jig is fitted with hardened steel bushings1 at the exact locations where holes need to be created.

- Drilling: The drill bit is guided directly through the bushing, which prevents the drill from "walking" or wandering off-center. This ensures every hole is positioned perfectly.

- Reaming & Boring: Jigs can also guide reamers or boring bars to enlarge existing holes to a precise diameter and location.

- Tapping: Some jigs can guide taps to ensure threads are cut straight and in the correct position.

By controlling the tool's location, the jig guarantees that the hole pattern is identical on every single part.

Improving Repeatability and Consistency

When you're making dozens or hundreds of parts, a jig is essential for consistency. It reduces the chance of human error that comes with measuring and marking each piece. An operator, even one with less experience, can load a part into a jig, perform the operation, and produce a part that is identical to all the others. This is fundamental to modern quality control and interchangeable parts2.

Enhancing Efficiency and Safety

- Efficiency: Jigs drastically reduce setup time per part. Instead of locating and clamping each part individually and then marking out features, the operator simply places the part in the jig and clamps it. This significantly boosts production speed.

- Safety: By securely holding the workpiece and guiding the tool, a jig makes the manufacturing operation safer for the operator. It provides a stable and predictable environment for the cutting process.

In essence, a jig is a solution for any operation that needs to be repeated accurately and efficiently across multiple parts.

What Is the Formal Definition of a Jig Tool?

The term "jig" is often used alongside "fixture." What is the specific, formal definition of a jig, and what makes it fundamentally different from a fixture?

A jig is a type of custom workholding device that controls the location and/or motion of another tool. Its defining feature is that it guides the cutting tool.

Diving Deeper into the Jig vs. Fixture Distinction

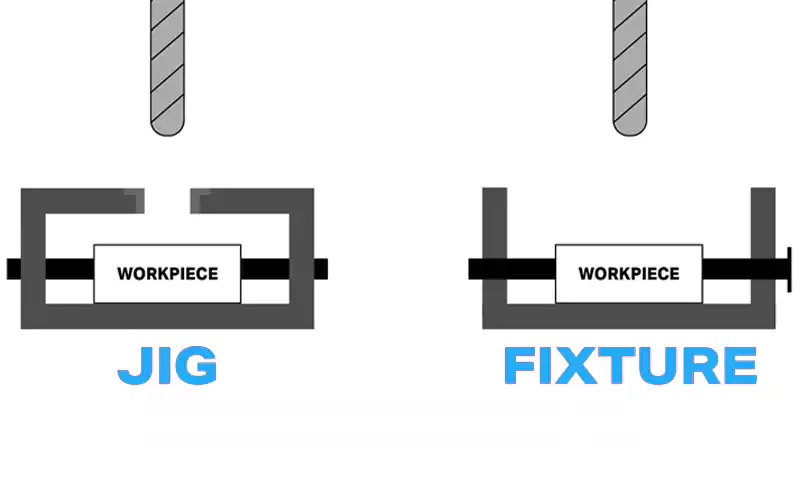

In manufacturing, precision in language is as important as precision in machining. For sourcing professionals and engineers like David, it's crucial to understand the formal definition of a jig, especially how it differs from a fixture. While both are types of workholding, they have one critical difference.

The Core Definition: Guiding the Tool

As I explained before, a jig's primary role is twofold: it holds the workpiece, and it guides the cutting tool. This tool guidance is the defining characteristic of a jig. Think of it this way: a jig acts as both a "map" for where to cut and a "guide rail" for the tool itself. The most common example is a drill jig with hardened steel bushings. The bushings force the drill bit to enter the workpiece at the exact right location and angle. The jig itself dictates the accuracy of the operation, not the machine's CNC controller or the operator's skill in positioning the tool.

Jig vs. Fixture: A Critical Distinction

This is where many people get confused, but the difference is simple:

- A jig holds the work and guides the tool.

- A fixture only holds the work in a specific location and orientation. The machine tool (e.g., the CNC mill's spindle) is responsible for guiding the tool path.

In a modern CNC environment like Allied Metal, fixtures are far more common. We secure a part in a fixture on the machine table, and our CNC program precisely guides the cutting tool to all the features. However, jigs are still incredibly valuable for secondary operations, manual drilling processes, or when adding features to existing parts where using a large CNC machine would be inefficient.

| Feature | Jig | Fixture |

|---|---|---|

| Primary Function | Holds the workpiece AND guides the cutting tool. | Only holds the workpiece in a known, fixed position. |

| Tool Interaction | The tool makes physical contact with the jig (e.g., via a bushing). | The tool does not touch the fixture (clearances are required). |

| Accuracy Control | Accuracy comes from the jig's design and construction. | Accuracy comes from the CNC machine's control system and program. |

| Common Operations | Drilling, reaming, tapping, boring (often manual or drill press). | Milling, turning, grinding, inspection (primarily CNC). |

| Complexity | Can be simple (template) to complex (box jig). | Can be simple (vise stops) to complex (hydraulic multi-part fixture3). |

Understanding this distinction ensures clear communication and proper selection of workholding for any manufacturing task.

What Are the Main Types of Jig Tools Used in Workshops?

If you need a jig for a project, what kinds are available? Are there standard designs for these tools, or is every jig completely custom?

There are several common types of jigs, including template, plate, channel, box, and indexing jigs. Each is designed to suit different part shapes and operational needs.

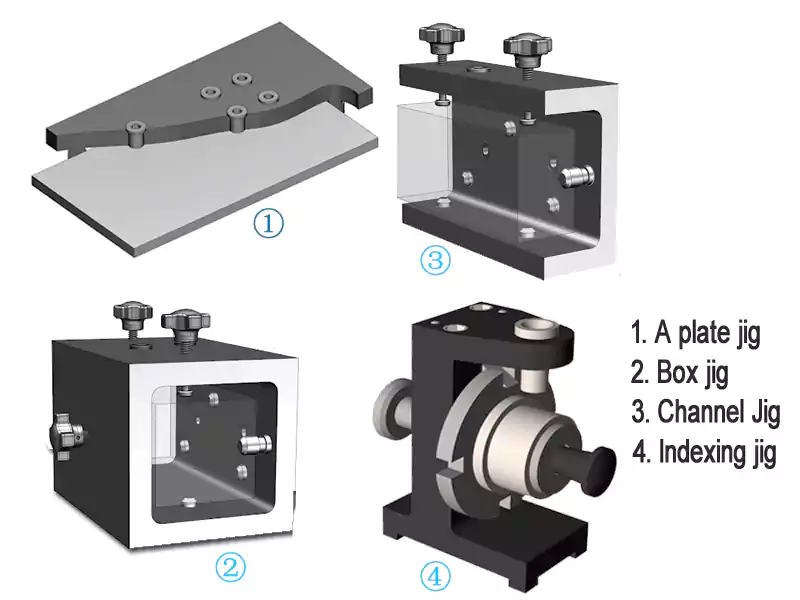

Diving Deeper into Common Jig Designs

While many jigs are custom-designed for a specific part, they often fall into several standard categories based on their construction and how they hold the workpiece. Knowing these types helps an engineer like David visualize how a part might be held for certain operations.

Here are some of the main types of jig tools:

- Template Jigs4:

- This is the simplest form of a jig. It's essentially a flat plate made of steel or another durable material that contains the hole pattern. The template is placed directly onto the workpiece and clamped. The operator then drills through the holes in the template. They are inexpensive to make but may offer less precision than more robust designs.

- Plate Jigs:

- Similar to a template jig but more robustly constructed. A plate jig is a plate with drill bushings that is clamped to the top of the workpiece. It provides better accuracy and durability for the guiding holes than a simple template.

- Channel Jigs:

- This type of jig is shaped like a channel (a U-shaped cross-section). The workpiece is placed inside the channel, and the jig can be designed to guide a tool from one, two, or three sides. It's useful for square or rectangular parts.

- Leaf Jigs (or Lid Jigs):

- These jigs feature a hinged leaf or lid that can be opened and closed. This design allows for quick and easy loading and unloading of the workpiece. The bushings are located on the leaf, which is closed and locked before the operation begins.

- Box Jigs:

- A box jig is designed to surround the workpiece, like a box. This allows for operations to be performed on multiple surfaces of the part without having to unclamp and reposition it. It offers excellent rigidity and accuracy for parts that need holes on different faces.

- Indexing Jigs:

- These are used to accurately drill holes or machine features in a circular pattern, such as on a flange or gear blank. The jig has an indexing mechanism (like a pin or plunger) that allows the workpiece to be rotated to precise angular positions between operations.

- Angle Jigs:

- Used to hold a workpiece at a specific angle relative to the cutting tool, for drilling angled holes.

The specific type of jig used is always determined by the geometry of the part and the requirements of the machining operation.

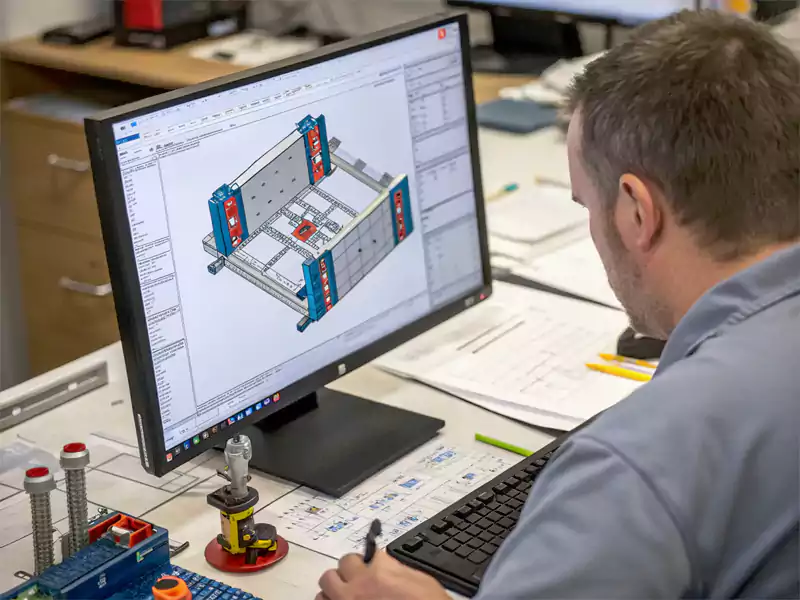

What Goes into Professional Jig and Tool Design?

Creating a good jig isn't just about drilling holes in a plate. What engineering principles and considerations go into designing a truly effective and reliable jig?

Professional jig design involves analyzing the part and operation, applying the 3-2-1 locating principle, selecting appropriate materials and bushings, and ensuring ergonomic efficiency, chip clearance, and cost-effectiveness.

Diving Deeper into the Design Process

Designing a high-quality jig is a specialized area of mechanical and manufacturing engineering. For engineers, understanding what goes into this process can help him appreciate the value of well-designed tooling for his projects. A professional jig designer considers many factors to ensure the final tool is accurate, durable, and efficient to use.

Understanding the Part and Operation

The process always begins with a thorough analysis of the part's engineering drawing and the specific operation to be performed. The designer must understand the critical dimensions, tolerances, and the material being machined.

Applying the 3-2-1 Principle of Location

As with any good workholding, the foundation of jig design is accurately and repeatably locating the workpiece. The 3-2-1 principle5 is a fundamental concept used to constrain the part in all six degrees of freedom. The jig will have fixed locating points (pins, pads, or surfaces) that the workpiece rests against, ensuring every part sits in the exact same position.

Material Selection and Construction

- Jig Body: The body of the jig is often made from steel or aluminum for rigidity and durability. For lighter-duty applications, engineering plastics can also be used.

- Drill Bushings: This is a critical component. A jig doesn't just have drilled holes; it has hardened steel bushings pressed into it. These bushings resist wear from the rotating drill bit and maintain the accuracy of the hole location over thousands of cycles. There are different types of bushings for different applications (e.g., press-fit, renewable for high-wear situations).

Ergonomics and Efficiency

A well-designed jig must be easy and fast for an operator to use.

- Loading/Unloading: The design should allow the workpiece to be loaded and unloaded quickly and easily. Features like leaf lids or quick-acting clamps are used for this.

- Clamping: The clamps should be simple to operate but provide adequate force without distorting the part.

- Chip Clearance: The design must allow metal chips produced during machining to escape easily, so they don't get packed in and interfere with the operation or damage the part.

Economic Considerations

Finally, the designer must balance the cost of manufacturing the jig with the expected savings it will generate in production. For a one-off part, a complex jig isn't worth it. For thousands of parts, a well-designed jig pays for itself many times over through increased speed, improved quality, and reduced scrap rates.

Conclusion

Jigs are essential manufacturing aids that hold a workpiece and guide a cutting tool. They ensure accuracy, repeatability, and efficiency, especially in drilling and boring operations.

- Understanding bushings is crucial for precision in drilling. Explore this link to learn how they enhance accuracy in hole placement. ↩

- Interchangeable parts are key to efficiency in production. Learn how they can transform your manufacturing process. ↩

- This link will explain the benefits of hydraulic fixtures in improving productivity and precision in manufacturing. ↩

- Explore this link to understand the basics of Template Jigs and their applications in woodworking, enhancing your project precision. ↩

- Understanding the 3-2-1 principle is crucial for effective jig design, ensuring precision and repeatability in manufacturing processes. ↩

319bet1, alright! Gonna try my luck here tonight. Hoping for some good vibes and even better wins. Time to roll the dice! 319bet1