Last updated: 7 January 2026 by Lucy

Motor failures often trace back to small rotating parts. When a shaft wears, bends, or vibrates, efficiency drops and noise rises fast. Many teams overlook this risk.

A motor shaft is the core rotating component that transfers torque from the motor to the load, and its accuracy, finish, and balance define motor efficiency, noise level, and service life.

I have seen many projects where the shaft design decided success or failure. That is why I want to walk you through motor shafts from an engineering and manufacturing point of view, based on real CNC shop experience.

What is a Motor Shaft?

Poor shaft definition leads to misalignment, early bearing wear, and wasted energy. Many designs fail because the shaft role is not fully understood at the start.

A motor shaft is a precision-machined cylindrical part that supports rotation, carries torque, and interfaces with bearings, gears, or couplings inside a motor system.

I usually explain motor shafts by breaking them into function, type, and design rules.

Core functions of a motor shaft

The shaft must transmit torque without twisting beyond limits. It must stay straight under load. It must also provide accurate bearing seats to keep rotation stable. Even small errors increase friction and noise.

In many motor-driven systems, the motor shaft also acts as part of a larger power transmission system. In these cases, it follows the same mechanical principles as a transmission shaft, including torque transfer, alignment, and fatigue control.

Common motor shaft types

In daily CNC work, I most often machine:

- Solid shafts, used for standard motors with moderate torque.

- Stepped shafts, where different diameters locate bearings and gears.

- Hollow shafts, used to reduce weight or pass cables or fluids.

- Splined or keyed shafts, used when torque transfer must be secure.

Basic design fundamentals

I always check these points with engineers:

- Diameter sized for torque and fatigue life1

- Fillet radii to reduce stress concentration

- Bearing fits defined by ISO tolerance classes

- Straightness and concentricity across all steps

These basics decide whether CNC machining can deliver a stable and quiet motor shaft.

Why CNC Machining is Ideal for Motor Shafts?

Manual machining and rough processes struggle to meet modern motor demands. As motors become faster and smaller, tolerance windows shrink.

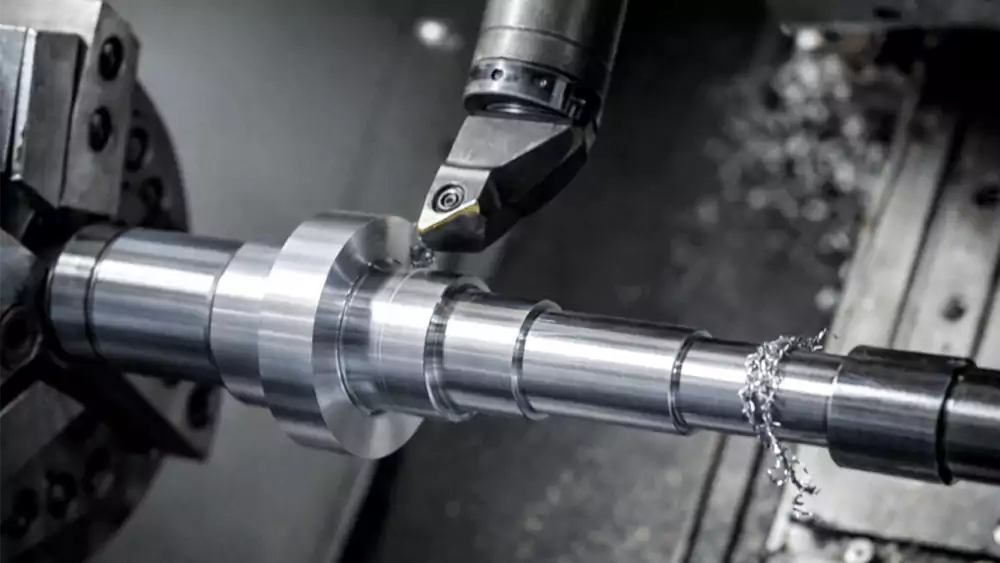

CNC machining delivers tight tolerances, repeatable accuracy, and flexible geometry control, making it ideal for high-performance motor shafts.

From my workshop perspective, CNC machining stands out for three reasons:

Precision and repeatability

CNC lathes and mills can hold diameters within ±0.005 mm when needed. More important, they repeat this across batches. This consistency keeps bearing preload and balance stable.

Design flexibility

With CNC, I can machine steps, grooves, threads, keyways, and splines in one setup. This reduces stack-up errors and saves time. Design changes also become easier during prototyping.

Surface finish control

Shaft journals often need Ra 0.8 µm or better. CNC turning with fine inserts or follow-up grinding makes this achievable. Better finish means lower friction and longer bearing life.

For engineers like David, this precision directly lowers risk during assembly and long-term use.

How CNC Motor Shafts are Made?

Many people think CNC machining is just cutting metal. In reality, quality comes from the full process chain.

CNC motor shafts follow a controlled workflow that starts with material choice and ends with inspection of size, finish, and balance.

I usually follow these steps in production.

Material selection

Common materials include:

- Carbon steel like C45 for general motors

- Alloy steel like 42CrMo2 for high torque

- Stainless steel for corrosion resistance

- Aluminum alloys for lightweight designs

Material choice affects machinability, heat treatment, and cost.

CNC turning and milling

Most shafts start on CNC lathes. Milling adds keyways or flats. For tight coaxiality, I prefer one-machine complete machining.

Heat treatment and finishing

Some shafts need quenching, tempering, or induction hardening. After heat treatment, I often re-machine or grind bearing seats to restore accuracy.

Inspection and control

Final checks include diameter, runout, concentricity, and surface roughness. For critical motors, I also check dynamic balance.

Case study: Servo motor shaft for industrial automation

I once supported an automation customer with repeated bearing failures. The issue was shaft runout.

| Parameter | Original Design | Optimized CNC Shaft |

|---|---|---|

| Material | C45 steel | 42CrMo |

| Shaft diameter | 18 mm | 18 mm |

| Runout | 0.03 mm | 0.008 mm |

| Surface roughness | Ra 1.6 µm | Ra 0.8 µm |

| Heat treatment | None | Q&T to 30–32 HRC |

| Bearing life | 6 months | Over 24 months |

After CNC process optimization, vibration dropped and motor life improved clearly.

Key Features and Common Applications

A motor shaft may look simple, but key features define performance in real use.

Critical shaft specifications include tolerance, finish, straightness, and balance, which directly affect motor stability and efficiency.

From my experience, engineers should focus on these points.

Critical specifications

- Diameter tolerance3: affects bearing fit and heat generation

- Concentricity: keeps rotation smooth at high speed

- Straightness: reduces uneven load on bearings

- Surface finish: lowers friction and noise

Ignoring any one of these often leads to hidden failures.

Common applications

CNC machined motor shafts are widely used in:

- Industrial automation and robotics

- Electric vehicles and e-bikes

- Medical devices like pumps and drives

- Power tools and high-speed spindles

Each application pushes different limits, but all rely on precision shafts.

Choose Allied Metal for Your CNC Motor Shaft Solutions

Choosing the wrong supplier adds risk to your motor system. Many failures start with poor communication or weak process control.

Allied Metal provides CNC motor shaft solutions backed by machining experience, strict quality control, and engineering-focused support.

As someone who started on the shop floor, I focus on practical results.

What we bring

- Over 20 years of CNC machining experience

- Support for prototypes and production runs

- Tight tolerance control and inspection reports

- Material and process advice based on real use

I work closely with engineers to match drawings to real manufacturing limits.

Conclusion & Call to Action

Precision motor shafts define motor performance. With the right CNC process and partner, you can reduce noise, extend life, and protect your design.If you need reliable CNC machined motor shafts, I invite you to explore Allied Metal’s precision solutions.

-

Understanding diameter sizing is crucial for ensuring the longevity and reliability of mechanical components. ↩

-

This resource will explain the benefits of 42CrMo in high torque scenarios, enhancing your understanding of material selection. ↩

-

Understanding diameter tolerance is crucial for ensuring proper bearing fit and minimizing heat generation in CNC machined components. ↩