Editor's Note: Last updated on November 22, 2025, by Lucy

I often meet engineers who feel stressed about machining because one wrong choice can waste time and money.

CNC machining is a digital manufacturing method that cuts materials with computer-controlled tools to produce accurate, repeatable parts for prototypes and production.

I learned early in my career that CNC machining becomes simple when we break it down into small pieces. Once we understand what affects accuracy, speed, material choice, and cost, we can make the right decisions without fear.

What is CNC Machining?

Many engineers struggle with unclear quotes, hidden tolerances, or inconsistent results from suppliers.

CNC machining means using programmed tool paths to remove material from metal or plastic blocks so parts match exact dimensions with high accuracy and repeatability.

CNC machining basics

I like to explain CNC machining as a digital version of traditional cutting. A computer controls the machine, the machine holds the tools, and the tools follow programmed paths. This means the results do not depend on operator skill. The results depend on programming, fixturing, tool choice, and machine capability.

Why CNC machining matters

CNC machining works for simple shapes and complex parts with tight tolerances. It also works for most metals and many plastics. This makes it one of the most flexible manufacturing technologies for engineers who need accuracy without making molds.

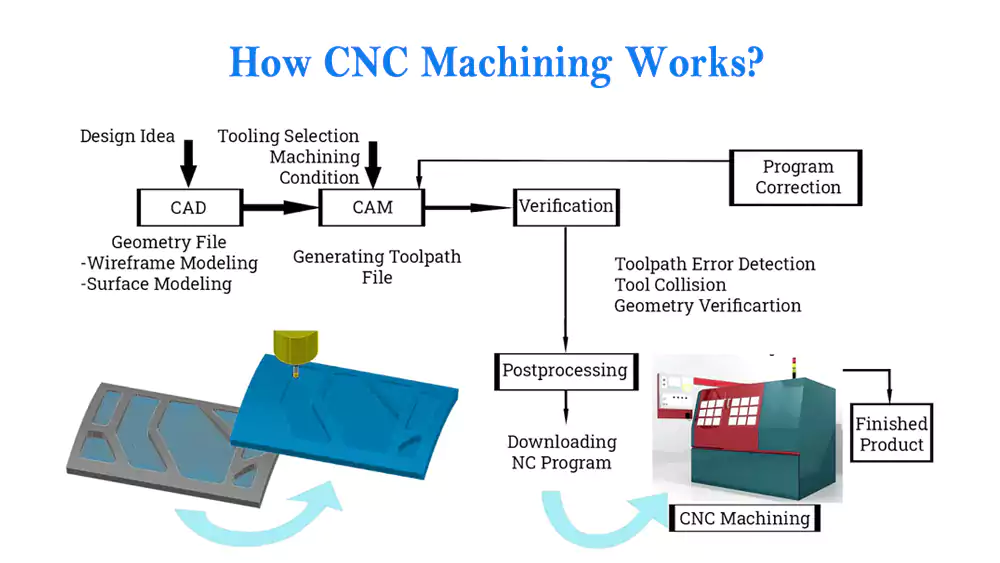

How CNC Machining Works?

I have seen many projects fail because teams do not understand what happens inside a CNC machine.

CNC machining works by processing a digital model (CAD), generating cutting instructions (CAM), and executing them through machine movements to remove material until the part takes shape.

CAD → CAM → CNC

The process starts with your 3D model. Then CAM software creates toolpaths. The machine reads these instructions and uses controlled movements to cut the workpiece. Every axis has a servo motor that follows the programmed coordinates.

Key factors that affect results

Three things usually decide part quality: tool rigidity, fixturing stability, and correct cutting parameters1. When all three work well, tolerances stay stable and surface quality improves.

Common Types of CNC Machining?

Many clients ask me which machining method they should choose because each method seems similar.

The main CNC machining types include CNC milling, CNC turning, drilling, grinding, and 5-axis machining for complex geometries.

CNC milling

CNC milling removes material with rotating tools. It works well for flat surfaces, pockets, channels, and 3D contours.

CNC turning

CNC turning rotates the workpiece. It is ideal for shafts, pins, and round features.

5-axis machining

5-axis machines tilt and rotate the part, so the tool can cut at many angles. These machines help reduce setups and improve accuracy for complex parts.

Case Study: Improving accuracy through toolpath optimization

I once ran a production job for a customer who needed 1,200 pieces of 7075-T6 brackets with a ±0.01 mm tolerance on two critical faces. The parts were small, but the tolerance was tight. I used a balanced cutting strategy and reduced tool stick-out to increase rigidity.

Here is the actual data we used:

| Parameter | Value |

|---|---|

| Material | 7075-T6 aluminum2 |

| Machine | 5-axis CNC mill3 |

| Critical tolerance | ±0.01 mm |

| Tool diameter | 6 mm carbide end mill |

| Stick-out length | 14 mm |

| Spindle speed | 18,000 RPM |

| Feed rate | 1,450 mm/min |

| Depth of cut | 0.3 mm |

| Batch size | 1,200 pcs |

This reduced tool chatter, improved part consistency, and cut cycle time by 12%. The customer received every batch with full traceability and zero rejections.

Materials Used in CNC Machining?

Many engineers tell me they feel unsure about material selection because each option has different properties.

CNC machining supports metals like aluminum, steel, copper alloys, titanium, and plastics including ABS, POM, PC, and PEEK, chosen based on strength, weight, heat, and cost needs.

Common materials

I often help customers choose materials. Aluminum works well for most general parts. Stainless steel gives corrosion resistance. Copper alloys help with conductivity. Plastics are great for light weight or chemical resistance.

Material comparison table

| Material | Strength | Machinability | Use Case |

|---|---|---|---|

| Aluminum 6061 | Medium | Easy | General parts, brackets |

| Aluminum 7075 | High | Medium | Aerospace, structural parts |

| Stainless Steel 304 | Medium | Hard | Food, medical parts |

| Stainless Steel 316 | High | Hard | Marine or corrosion-critical |

| Copper | Soft | Medium | Electrical parts |

| PEEK | High | Hard | High-heat plastic components |

Design Considerations for CNC Machining?

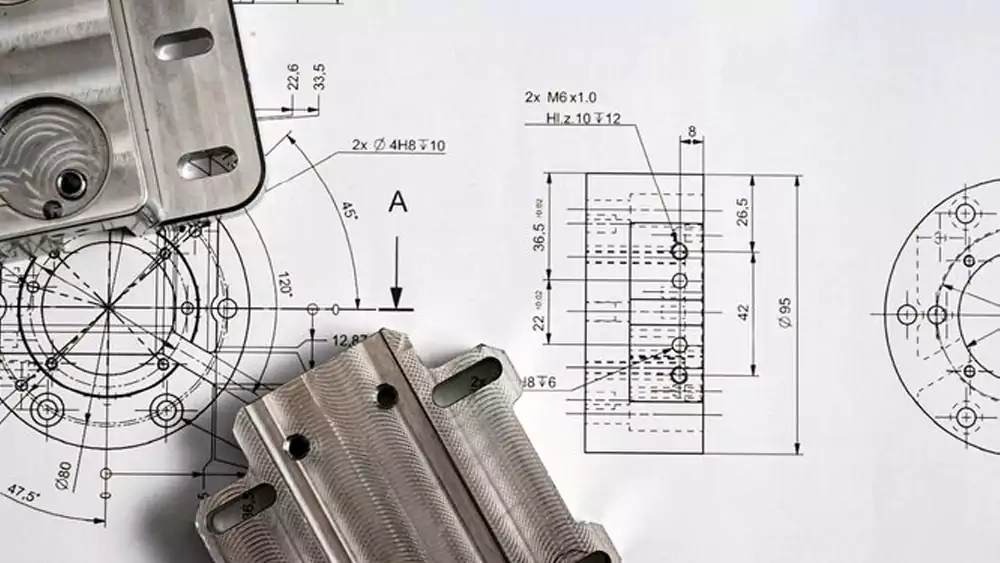

Many drawings I receive include features that are hard to machine or too expensive.

Design for CNC machining focuses on manufacturable tolerances, proper wall thickness, clear radii, correct thread sizes, and simplified geometry.

Tolerances

Tight tolerances increase machining time. I always suggest using tight tolerances only where needed.

Wall thickness

Thin walls may vibrate or deform. A minimum of 0.8–1.0 mm for metals is usually safe.

Internal radii

Sharp corners take more passes. Adding radii improves tool life and reduces cost.

Industrial Applications of CNC Machining?

Customers often ask whether CNC machining works for their specific industry.

CNC machining is used in aerospace, robotics, automobiles, medical devices, automation equipment, electronics, and industrial machinery for precise functional parts.

Application breakdown

- Aerospace: structural brackets, housings, tooling

- Robotics: joints, frames, actuators

- Automotive: precision metal inserts, fixtures

- Medical: custom implants, surgical tools

- Automation: machine frames, end-effectors

CNC machining fits these fields because it gives predictable tolerance control4 and strong material choices.

How to Reduce Costs?

I often help engineers cut machining costs without changing part performance.

Cost reductions come from simpler geometry, relaxed tolerances, better material choices, grouped orders, and clear drawings that match realistic machining rules.

Practical cost-saving tips

- Avoid deep pockets with small radii

- Use standard thread sizes

- Use aluminum for prototypes

- Combine machining steps

- Increase batch sizes

- Provide 3D + 2D drawings with tolerances only where needed

Advantages of CNC Machining?

I hear many people compare CNC machining with 3D printing or casting and wonder which one they should pick.

CNC machining offers high accuracy, repeatability, strong materials, tight tolerances, smooth finishes, and broad material compatibility for both prototyping and production.

Key advantages

- Works with metals and plastics

- High strength and durability

- Tight tolerance capability

- Great for prototypes and production

- Fast lead times

- Good for complex shapes

- Excellent surface finish

Conclusion

CNC machining stands out because it delivers reliable accuracy, strong materials, repeatable quality, and fast turnaround without the need for molds. It also gives engineers full control over tolerances, geometry, and production costs. This makes it one of the most dependable methods for both prototypes and production runs.

If you want consistent quality, clear communication, and a machining partner who understands real engineering needs, you can reach out to me and my team at Allied Metal. I am always ready to review your drawings, offer practical suggestions, and help you move your project forward with confidence.

-

Exploring cutting parameters can help you enhance machining efficiency and achieve better results. ↩

-

Explore this link to understand the unique properties of 7075-T6 aluminum, which is crucial for high-performance applications. ↩

-

Discover how 5-axis CNC milling enhances precision and efficiency in manufacturing, making it essential for complex parts. ↩

-

Discover why predictable tolerance control is crucial for maintaining high standards in manufacturing processes. ↩