Getting complex parts made exactly right can be tough. Traditional methods often struggle with consistency and precision, leading to wasted material and time. I remember facing these issues early in my career.

CNC machining is a manufacturing process where pre-programmed computer software directs the movement of factory tools and machinery. It uses computer numerical control (CNC) to precisely remove material from a workpiece, shaping it into the desired final part.

Understanding this process helped me build my business and serve clients better. It takes a digital design and turns it into a physical object with incredible accuracy. Let's break down how it all works, step by step. Knowing these details is key whether you're designing parts or running a shop.

What are the machining processes that can be performed on a CNC machine?

Are you wondering just how versatile a CNC machine really is? Many people only think of simple cutting, but these machines can do much more. It can be confusing to grasp the full range.

CNC machines perform various subtractive processes, including milling (cutting complex shapes), turning (shaping cylindrical parts), drilling, boring, tapping (creating threads), grinding (finishing surfaces), and routing, all guided by computer commands.

These machines are the workhorses of modern manufacturing. They combine precision with versatility. Let me explain some of the most common machining processes I use daily in my shop:

Common CNC Machining Processes Explained

- Milling: This is probably the most common process. A rotating cutting tool1 removes material from a stationary workpiece. We use it for creating flat surfaces, slots, pockets, and complex 3D contours. Think of parts like engine blocks or molds. Multi-axis milling machines (3, 4, or 5-axis) allow for incredibly intricate geometries.

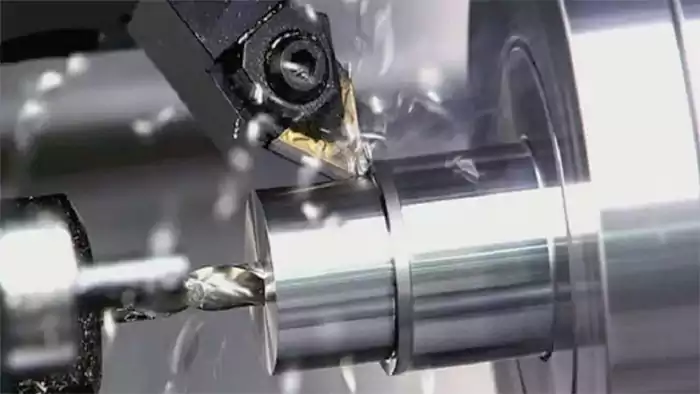

- Turning: Here, the workpiece rotates while a stationary cutting tool removes material. This is done on a CNC lathe and is perfect for creating cylindrical or conical shapes like shafts, pins, and bolts. It's efficient for symmetrical parts.

- Drilling, Boring, Tapping: While simple, these are fundamental. CNC ensures holes are precisely located, sized (drilling/boring), and threaded (tapping). Boring specifically enlarges an existing hole to a very precise diameter.

- Grinding: This uses an abrasive wheel2 to achieve very fine finishes and extremely tight tolerances, often as a final step after milling or turning.

Understanding which process fits your part best is crucial for efficient production.What is a CNC procedure?

You have a design, but how does it become a finished part? Many designers, like Jacky, know CAD but might be unclear on the steps that follow. It seems complex from the outside.

A CNC procedure is the systematic workflow turning a digital design into a physical part. It includes CAD design, CAM programming (generating toolpaths and G-code), machine setup (loading material, tools, fixtures), and finally, automated machining execution.

CNC Machining Procedure Steps Think of the CNC procedure as the roadmap from concept to reality. Each step is critical. In my experience, skipping or rushing any part leads to problems down the line.

Breakdown of the CNC Machining Procedure

- CAD Model Creation3: It all starts with a 2D drawing or 3D solid model created using Computer-Aided Design (CAD) software. This digital blueprint defines the geometry of the part. Accuracy here is paramount.

- CAM Programming: Computer-Aided Manufacturing (CAM) software takes the CAD model and generates the machine instructions, called G-code. This involves planning the toolpaths, selecting tools, setting cutting speeds and feeds, and simulating the process to avoid errors. I find good CAM programming saves enormous amounts of time and material.

- Machine Setup: Before machining, the operator prepares the CNC machine. This involves securely clamping the raw material (workpiece) onto the machine bed using fixtures, loading the correct cutting tools into the tool holder, and setting the work offset4 (telling the machine where the workpiece is).

- Machining Execution: The operator loads the G-code program into the CNC controller. The machine then automatically executes the programmed operations, cutting away material precisely according to the instructions. The operator monitors the process, making adjustments if needed.

Following this procedure carefully ensures parts are made correctly and efficiently every time.What is a process plan for CNC machining?

Just hitting 'start' on a CNC machine isn't enough for complex jobs. Without a clear plan, you risk errors, wasted time, and inconsistent quality. I learned early on that planning is everything.

A CNC machining process plan is a detailed document outlining the exact sequence of manufacturing operations, tools, fixtures, cutting parameters (speeds, feeds), and quality checks needed to produce a specific part efficiently and to specification.

CNC Machining Process Plan A solid process plan is the key to repeatable success in CNC machining. It ensures everyone involved knows exactly how a part should be made. Let's look at what goes into it:

Key Elements of a CNC Process Plan

- Sequence of Operations: Which machine? What steps first? (e.g., Face mill top surface -> Drill holes -> Mill pocket -> Tap threads). This ensures logical material removal and maintains accuracy.

- Machine and Fixturing: Specifies which CNC machine to use and how the workpiece will be held (e.g., vise, custom fixture). Proper workholding is crucial for stability and precision.

- Tooling List: Details every cutting tool needed (e.g., end mills, drills, taps), including their dimensions and material.

- Cutting Parameters5: Defines the optimal spindle speed (RPM) and feed rate (how fast the tool moves) for each operation and material. This impacts surface finish, tool life, and cycle time.

- Quality Control Points: Specifies when and how to inspect the part during and after machining (e.g., measure hole diameter after drilling, final inspection using CMM).

Creating this plan takes time upfront but prevents costly mistakes and delays later. It standardizes production and makes quoting jobs much more accurate.

What are the operations in a CNC machine?

It's clear CNC machines cut material, but what specific actions do they perform? Understanding the different types of cuts helps designers optimize parts for manufacturability.

CNC machine operations refer to the specific material removal actions controlled by the program. Common operations include facing, contouring, pocketing, slotting, drilling, boring, reaming, and tapping to shape the workpiece.

Each operation uses specific tools and movements to achieve a desired feature on the part. Let's dive into some common ones I see every day:

Detailed Look at CNC Operations

- Facing: Creates a flat, smooth surface on the workpiece, often as the first operation to establish a reference plane. A face mill tool is typically used.

- Contouring: The cutting tool follows a path along the edge of the part to create its outside shape or profile. This can be simple straight lines or complex curves.

- Pocketing: Removes material from inside a defined boundary on the workpiece surface, creating a cavity or "pocket". Think of recesses for components.

- Slotting: Mills a narrow channel or groove into the workpiece. This can be done with an end mill or a dedicated slotting tool.

- Drilling: Creates holes using a drill bit.

- Boring: Accurately enlarges an existing hole to a precise diameter and improves its roundness using a boring bar.

- Reaming: A finishing operation that slightly enlarges a drilled hole to a very precise diameter with a smooth finish.

- Tapping: Cuts internal threads into a hole using a tap tool.

Knowing these operations allows designers like Jacky to create features that are easily and efficiently produced using standard CNC techniques.How accurate is CNC machining?

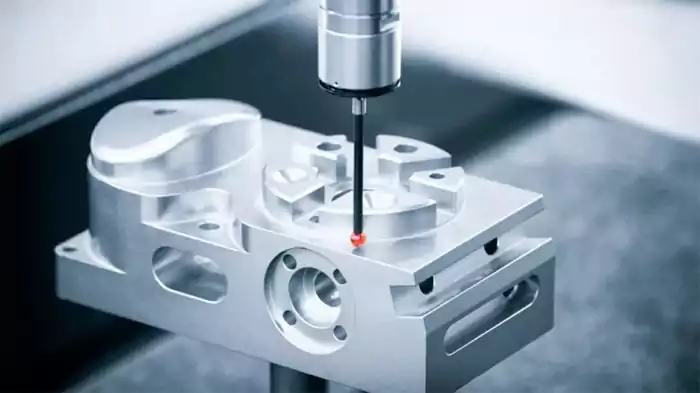

You need parts with extremely tight tolerances, perhaps for aerospace or medical devices. Can CNC machining deliver the required precision consistently? Doubts about accuracy can hold back projects.

CNC machining is renowned for its high accuracy and repeatability. Standard tolerances are often within ±0.005 inches (0.127 mm), but tighter tolerances down to ±0.001 inches (0.025 mm) or even ±0.0001 inches (0.0025 mm) are achievable.

Accuracy of CNC Machining The level of accuracy depends on several factors, but modern CNC technology is incredibly capable. I've consistently produced parts with micron-level precision for demanding clients.

Factors Influencing CNC Accuracy

- Machine Quality & Calibration: High-end machines with rigid construction, thermal stability, and regular calibration achieve the best results. The precision of the machine's axes and spindle is fundamental.

- Tooling: Sharp, high-quality cutting tools and rigid tool holders minimize deflection and vibration. Tool wear must be monitored and compensated for.

- Material Properties: Different materials behave differently during cutting. Hardness, stability, and thermal expansion affect the final dimensions.

- Cutting Parameters: Spindle speed, feed rate, and depth of cut need to be optimized for the specific material and operation to minimize tool pressure and heat generation.

- Workholding: The workpiece must be held securely and without distortion.

- Environmental Control: Temperature fluctuations in the workshop can affect the machine and workpiece dimensions. Climate-controlled environments help maintain top accuracy.

- Programming & Operator Skill: Optimal toolpaths generated by CAM software and careful setup/monitoring by a skilled operator are essential.

We routinely use Coordinate Measuring Machines (CMMs) to verify part dimensions against the CAD model, ensuring we meet even the strictest tolerance requirements.Conclusion

The CNC machining process transforms digital designs into precise physical parts through computer-controlled operations like milling and turning. It involves design, programming, setup, and execution, delivering high accuracy for many industries.

Footnotes:

-

Learn about the mechanics of rotating cutting tools and their role in achieving high-quality milling results. ↩

-

Learn about the function of abrasive wheels in machining, which is essential for achieving fine finishes and tight tolerances. ↩

-

Exploring CAD Model Creation will enhance your knowledge of how digital designs translate into physical parts, crucial for effective machining. ↩

-

Learning about work offsets is vital for accurate machining, ensuring that the machine knows the exact position of the workpiece. ↩

-

Exploring cutting parameters can enhance your knowledge of machining efficiency, tool longevity, and product quality. ↩