Editor’s Note (Update – October 2025):

To better demonstrate how Wood CNC machining handles complex geometries and high-finish requirements, we’ve added a new case study below. It focuses on the production of a wooden children’s toy — a challenging component demanding both intricate shaping and exceptional surface smoothness.

Trying to create intricate wood designs but finding manual methods slow and imprecise? This can lead to inconsistent results, wasted material, and project delays.

Wood CNC machining uses computer-controlled routers and mills to precisely cut and shape wood. It enables complex designs, consistent quality, and efficient production for various wood types.

At Allied Metal, our bread and butter has always been precision CNC machining of metals and plastics, alongside our 3D printing and rapid prototyping services. However, the principles of CNC machining – computer numerical control – are incredibly versatile and apply to a wide range of materials, including wood. Many engineers might consider wood for specific applications in their automation projects, like jigs, fixtures, prototypes, or even some structural or aesthetic elements. My insight here is that, honestly, CNC machining works great with wood—you just need the right type and tools. The precision and repeatability of CNC can transform woodworking. Hardwoods are my go-to for clean detail, but softwoods can be perfect for quick, cost-effective jobs. Let's explore what Wood CNC machining is all about and how you can leverage it.

What Exactly Is Wood CNC Machining?

You hear about CNC for metals, but how does it apply to wood? What makes "Wood CNC Machining" a specific and valuable technique for your projects?

Wood CNC machining is the process of using computer-controlled machines, typically routers or mills, to automatically cut, carve, drill, and shape wooden materials based on a digital design file.

Diving Deeper into the Definition

Wood CNC machining is essentially the application of Computer Numerical Control (CNC) technology to the woodworking industry. Just like with metals or plastics, a digital design (created in CAD software) is translated into a set of instructions (G-code) that a CNC machine follows. Instead of a machinist manually guiding a cutting tool, the computer directs the machine’s movements with high precision.

For wood, the most common type of CNC machine is a CNC router1, which typically uses a high-speed spindle2 to rotate cutting bits similar to those used in handheld routers, but with much greater accuracy and power. CNC milling machines can also be used for wood, especially for more heavy-duty or 3D contouring work.

The process allows for:

- Complex Shapes and Designs: Intricate patterns, curves, 3D carvings, and precise joinery that would be incredibly difficult or time-consuming by hand.

- High Repeatability: Once the program is set, the CNC machine can produce identical parts consistently, which is crucial for production runs.

- Efficiency: Automated cutting reduces manual labor and can significantly speed up production, especially for multiple identical items.

- Material Optimization: Software can help arrange parts on a sheet of wood to minimize waste (nesting).

Whether it's for custom furniture, cabinetry, signage, architectural millwork, prototyping, or creating jigs and fixtures, Wood CNC machining offers a powerful way to transform digital designs into physical wooden objects. For someone like David designing elements for industrial automation, this could mean quickly creating custom mounting panels, enclosures, or even robust prototypes.

Is Wood Really Suitable for CNC Machining?

Wood is a natural material with variations. Can it truly be shaped precisely by CNC machines, or is it too unpredictable compared to metals or plastics?

Yes, wood is very suitable for CNC machining. Many types, from hardwoods and softwoods to engineered woods like MDF and plywood, can be accurately cut, carved, and shaped.

Diving Deeper into Wood's Machinability with CNC

Absolutely, wood is an excellent candidate for CNC machining. In fact, CNC routers and mills3 have revolutionized woodworking, bringing a new level of precision, complexity, and efficiency to the craft and to industrial production. My insight that "CNC machining works great with wood" comes from seeing its capabilities firsthand.

While wood is a natural material with inherent variations like grain direction, knots, and moisture content (which can affect machining), these are well-understood factors that can be managed with proper techniques and material selection.

Why Wood Works Well with CNC:

- Workability: Most woods are significantly softer and easier to cut than metals, meaning machining can often be done at higher speeds with less force, potentially leading to faster cycle times.

- Versatility: CNC machines can perform a wide range of operations on wood, including:

- Routing: Cutting out complex 2D shapes, creating pockets, and profiling edges.

- Carving: Producing intricate 3D reliefs and sculptures.

- Drilling: Creating precise holes for joinery or hardware.

- Milling: Similar to routing but can involve more robust cutters for deeper cuts or 3D contouring.

- Engraving: Adding text or detailed patterns.

- Variety of Materials: A vast range of wood types can be CNC machined, from softwoods and hardwoods to engineered wood products, each offering different aesthetics and mechanical properties.

- Cost-Effectiveness: For many applications, especially intricate designs or batch production, Wood CNC machining can be more cost-effective than manual methods due to speed, repeatability, and reduced labor.

Of course, successful Wood CNC machining requires understanding the specific characteristics of the wood being used, selecting the right cutting tools, and optimizing cutting parameters (feed rate, spindle speed, depth of cut). For instance, hardwoods will machine differently than softwoods or MDF. But the fundamental capability of CNC technology to precisely control cutting tools makes it a powerful partner for working with wood. For purchasing managers, this means wood can be a viable option for certain components where its properties are advantageous.

What's Considered the Best Wood for CNC Machining Projects?

If you're starting a Wood CNC machining project, which wood should you pick? Is there a single "best" type, or does it depend on your specific needs?

The "best" wood depends on the project. Hardwoods like maple or cherry offer fine detail and durability. MDF provides consistency. Softwoods are cost-effective for simpler, quicker jobs.

Diving Deeper into Ideal Wood Characteristics for CNC

There isn't one single "best" wood for all CNC machining applications, as the ideal choice depends heavily on the project's requirements: the desired level of detail, strength, appearance, budget, and end-use. However, certain characteristics make some woods generally better suited for CNC work than others. I believe hardwood excels in detailed workmanship, while softwood offers advantages in processing speed and cost control.

General Characteristics of "Good" Wood for CNC:

- Consistent Density and Grain: Woods with a uniform density and a relatively straight, tight grain tend to machine more cleanly and predictably. This minimizes issues like tear-out (where wood fibers get pulled out instead of cut cleanly) or fuzzing.

- Stability: Woods that are less prone to warping, twisting, or cupping with changes in humidity are preferred, especially for larger or more precise parts. Kiln-dried wood is essential.

- Good Machinability: This refers to how easily the wood can be cut, how well it holds detail, and the quality of the resulting surface finish.

- Minimal Defects: Woods with fewer knots, voids, or resin pockets are generally better, as these can interfere with the cutting process or affect the appearance and strength of the final part.

- Finishing Qualities: How well the wood accepts stains, paints, or clear finishes can also be a factor.

Specific Wood Types Often Considered "Best" for Certain CNC Attributes:

- For Fine Detail and Smooth Finish: Hardwoods like Hard Maple, Cherry, Walnut, and Alder are excellent. They have tight grains and consistent density, allowing for crisp edges and intricate carvings. This aligns with my preference for hardwoods for clean detail.

- For Consistency and Stability (Engineered Woods): Medium-Density Fiberboard (MDF)4 and High-Density Fiberboard (HDF) are very popular for CNC routing because they are extremely uniform, stable, have no grain direction to worry about, and machine very smoothly. Plywood, especially high-quality Baltic Birch plywood, is also great for its stability and strength.

- For Cost-Effectiveness and Ease of Machining (Softwoods): Woods like Pine or Poplar can be good for less demanding applications, prototypes, or when cost is a primary driver. They machine very easily but are softer and more prone to denting and tear-out.

Ultimately, the "best" wood is the one that best meets the specific balance of performance, aesthetics, and cost requirements for David's project.

📘 Case Study: High-Precision CNC Machining of a Wooden Children’s Toy

A production manager at a wooden toy workshop sought to improve both safety and quality for a new complex-shaped children’s toy, featuring curved edges, interlocking joints, and organic 3D contours. Manual carving couldn’t achieve the required precision or surface smoothness needed for a child-safe finish.

Project Overview

| Parameter | Manual Production | CNC Machining (5-axis router, 6 mm ball nose bit) |

|---|---|---|

| Material | European Beech (Moisture 7%) | European Beech (Moisture 7%) |

| Part Dimensions | 210 × 180 × 45 mm | 210 × 180 × 45 mm |

| Average Tolerance | ±0.8 mm | ±0.15 mm |

| Cycle Time (per piece) | 28 minutes | 12 minutes |

| Reject Rate | 9% | <1% |

| Surface Finish (Ra) | 5.5 µm | 1.8 µm (after light sanding) |

Machining Parameters

- Spindle speed: 18,000 rpm

- Feed rate: 2,800 mm/min

- Layer step-over: 0.5 mm (finishing pass)

- Tool path strategy: Adaptive roughing + spiral 3D finishing

- Tooling: Solid carbide ball nose, polished flutes for hardwoods

- Vacuum hold-down: 5-zone vacuum table to secure small curved parts

- Dust extraction: 500 CFM HEPA-filtered collection system

Results

Using precision Wood CNC machining, the team produced toy components with:

- Perfectly smooth, child-safe surfaces, requiring only a light hand polish before applying a non-toxic water-based finish.

- Consistent curvature and fit accuracy across 200 units, ensuring flawless assembly of interlocking features.

- Dimensional repeatability within ±0.15 mm, even on fine contour transitions.

- Surface gloss uniformity within ±5%, verified via optical gloss measurement.

Outcome

The production manager summarized the impact:

“CNC machining allowed us to meet both the safety and aesthetic standards of premium wooden toys. The precision was so high that each part fits perfectly without force, and the finish feels silk-smooth right off the router.”

Key Takeaways

- Enhanced child safety through splinter-free surfaces and accurate joint fits.

- Over 50% reduction in finishing time, minimizing hand sanding.

- Improved yield and repeatability, essential for batch production of premium toys.

This case demonstrates how Wood CNC machining can achieve fine detailing, smooth finishes, and safety-grade precision, even for complex, organic-shaped consumer products like children’s toys.

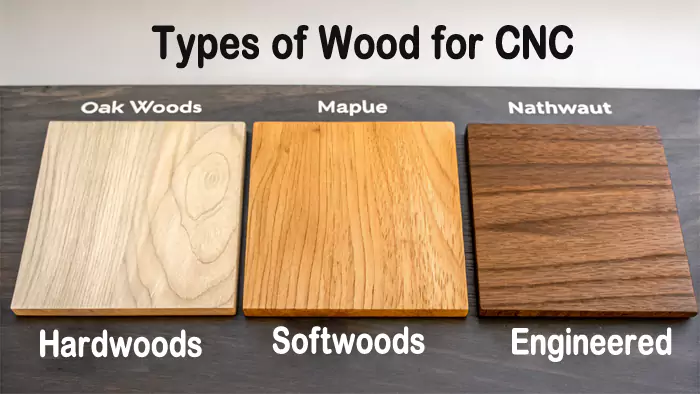

Hardwoods, Softwoods, or Engineered Woods: Which Type Is Best for Your CNC Project?

Wood comes in many forms. Should you use solid hardwoods, softwoods, or an engineered wood product like MDF or plywood for your Wood CNC machining needs?

Hardwoods offer detail and durability. Softwoods are cost-effective for simpler jobs. Engineered woods like MDF or plywood provide excellent stability and consistency for CNC machining.

Diving Deeper into Wood Categories for CNC

Understanding the broad categories of wood and their general characteristics is crucial when selecting material for Wood CNC machining. Each type brings different advantages and challenges to the table.

1. Hardwoods:

- Examples: Oak, Maple, Cherry, Walnut, Ash, Birch, Alder.

- Characteristics: Come from deciduous trees (trees that lose their leaves annually). They are generally denser, harder, and stronger than softwoods. Grain patterns can be very attractive.

- CNC Machinability:

- Pros: Can hold very fine detail and sharp edges, resulting in crisp carvings and clean profiles. They offer excellent durability and wear resistance for the finished part. My preference for hardwoods for clean detail stems from these qualities. They also tend to finish beautifully.

- Cons: More expensive than softwoods or most engineered woods. They are harder on cutting tools, requiring sharper bits and potentially slower feed rates or shallower depths of cut to prevent burning or excessive tool wear. Some oily or very dense hardwoods can be challenging.

- Best For: High-quality furniture, detailed carvings, cabinetry, musical instruments, durable components, projects where appearance and detail are paramount.

2. Softwoods:

- Examples: Pine, Fir, Cedar, Spruce, Redwood.

- Characteristics: Come from coniferous trees (evergreens). They are generally less dense, softer, and lighter than hardwoods. Grain patterns are often more prominent and can be less consistent.

- CNC Machinability:

- Pros: Generally less expensive and easier/faster to machine than hardwoods due to their lower density. Less wear on cutting tools.

- Cons: More prone to denting, scratching, and tear-out, especially around knots or inconsistent grain. Fine detail can be "fuzzy" or less crisp. Can exude resin (pitch), which can gum up tools.

- Best For: Cost-sensitive projects, prototypes, construction framing, paint-grade projects where fine detail is less critical, rustic-style items. This matches my thought that softwoods are good for quick, cost-effective jobs.

3. Engineered Woods:

- Examples: Medium-Density Fiberboard (MDF), High-Density Fiberboard (HDF), Plywood5 (especially Baltic Birch), Particle Board.

- Characteristics: Man-made products created by bonding wood fibers, veneers, or particles together with adhesives.

- CNC Machinability:

- Pros: MDF/HDF6 are extremely consistent, stable (minimal warping/twisting), have no grain direction to worry about, and machine very smoothly, yielding excellent paintable surfaces. Plywood (especially Baltic Birch) offers good strength, stability, and holds screws well. Generally cost-effective.

- Cons: MDF/HDF produce very fine dust (requiring good dust extraction), are very abrasive on cutting tools (carbide tools are essential), and don't have the natural beauty of solid wood (edges need finishing). They don't hold screws as well on the edges. Plywood layers can sometimes splinter or tear out on edges if not machined carefully.

- Best For: MDF/HDF are ideal for paint-grade cabinetry, jigs, fixtures, templates, signage, and parts requiring smooth, stable surfaces. Plywood is great for structural components, cabinet boxes, and projects needing good strength-to-weight.

For David, if he needs a quick, cheap prototype or a simple jig, a softwood or MDF might be fine. For a presentable or durable component, a hardwood or high-quality plywood would be better.

What Size Parts and Tolerances Can Wood CNC Machining Achieve?

When designing for Wood CNC machining, what are the practical limits on part size? And how precise can you expect the final wooden components to be?

Part size is limited by the CNC machine's bed. Tolerances for Wood CNC machining are typically looser than metalwork, around ±0.2mm to ±0.5mm, influenced by wood type and stability.

Diving Deeper into Size and Precision Capabilities

Understanding the practical capabilities regarding part size and achievable tolerances is important when David considers Wood CNC machining for his projects.

Part Size:

- The maximum size of a part that can be CNC machined from wood is primarily determined by the travel limits (X, Y, and Z axes) of the CNC machine's bed and gantry.

- CNC routers for wood often come in standard sheet good sizes, such as 4x8 feet (approx. 1.2x2.4 meters) or 5x10 feet (approx. 1.5x3 meters), allowing for large panels to be processed. Some industrial machines are even larger.

- The Z-axis travel (height) determines the maximum thickness of the material or the depth of 3D carving possible. This can range from a few inches to over a foot on larger machines.

- For parts larger than the machine bed, designs might need to be broken into smaller sections that can be machined individually and then assembled.

Tolerances:

- While CNC machining is inherently precise, the tolerances achievable with wood are generally looser than those expected with metal machining. This is due to the nature of wood itself:

- Material Variability: Wood is a natural, hygroscopic material (it absorbs and releases moisture), which can cause it to expand, contract, warp, or twist with changes in humidity and temperature, even after machining.

- Grain Direction and Density: These can affect how the wood responds to cutting forces, potentially leading to minor variations.

- Tool Wear and Deflection: While less of an issue than with metals, tool sharpness and rigidity still play a role.

- Typical Tolerances: For general Wood CNC machining, tolerances might be in the range of ±0.2 mm to ±0.5 mm (approx. ±0.008" to ±0.020"). Tighter tolerances are possible with stable materials (like high-quality MDF or very stable hardwoods), careful setup, sharp tooling, and controlled environmental conditions, but expecting the sub-±0.05mm (±0.002") tolerances common in precision metalworking is usually unrealistic for most wood applications.

- Achieving Tighter Fits: For joinery or press-fits, designers often account for wood's variability by designing features that allow for some compression or by planning for slight adjustments during assembly.

For David's applications in industrial automation, if he needs very high precision for a wood component that interfaces with metal parts, these tolerance capabilities must be carefully considered. Secondary fitting or adjustment might be part of the plan.

How Do You Pick the Right Cutting Tools for Wood CNC Machining?

The cutting tool is where the action happens in CNC. How do you select the best bits for machining wood to get clean cuts and the desired features?

Select tools based on wood type (hard, soft, engineered), operation (cutting, carving, V-grooving), and desired finish. Carbide tools are often preferred for wood due to durability and sharpness.

Diving Deeper into Wood CNC Tool Selection

Choosing the right cutting tool (often called a "bit" for CNC routers) is absolutely critical for successful Wood CNC machining. Using the wrong bit can lead to poor surface finish, tear-out, burning, excessive tool wear, or even damage to the workpiece or machine. My experience tells me this is just as important as selecting the right end mill for metal.

Key Factors in Tool Selection:

-

Tool Material:

- High-Speed Steel (HSS): Less expensive, suitable for softwoods and some light-duty hardwood work. They dull faster than carbide, especially with abrasive materials.

- Solid Carbide: More expensive but significantly harder, sharper, and more durable than HSS. They retain their cutting edge much longer, especially when cutting hardwoods, plywood, and MDF (which is very abrasive). Carbide is generally the preferred choice for most professional Wood CNC machining due to its performance and longer life.

- Carbide-Tipped: A steel body with carbide cutting edges brazed on. A compromise between HSS and solid carbide, often used for larger diameter bits.

-

Tool Type (Geometry):

- Straight Flute Bits: Simple, general-purpose bits for cutting grooves or dados.

- Spiral Flute End Mills: Very common and versatile.

- Up-Cut Spiral: Pulls chips upwards, good for clearing material quickly from pockets and grooves. Can cause some fuzzing or tear-out on the top surface of delicate materials.

- Down-Cut Spiral: Pushes chips downwards, providing a very clean top surface finish. Excellent for cutting sheet goods where edge quality on the top is critical. Chip evacuation from deep pockets can be an issue.

- Compression Spiral (Up-Down Cut): Combines up-cut and down-cut flutes. The bottom part pulls chips up, the top part pushes chips down. Ideal for cutting laminated materials like plywood or melamine, as it produces clean edges on both top and bottom surfaces.

- V-Groove Bits (V-Bits): Used for engraving, lettering, and creating chamfered edges or decorative V-shaped grooves. Come in various angles (e.g., 60°, 90°).

- Ball Nose End Mills: Have a rounded tip, used for 3D contouring, carving, and creating rounded fillets.

- Spoilboard Surfacing Bits (Fly Cutters): Large diameter bits used for flattening or surfacing the machine's spoilboard or large slabs of wood.

-

Number of Flutes:

- Fewer flutes (e.g., 1 or 2) allow for larger chip gullets and better chip evacuation, good for fast material removal in softer woods.

- More flutes (e.g., 3 or 4) can provide a smoother finish but require appropriate feed and speed adjustments to prevent chip packing. Two-flute bits are very common for general wood routing.

-

Tool Diameter and Length:

- Choose a diameter appropriate for the feature size and material removal rate.

- Use the shortest possible cutting length needed for the job to maximize rigidity and minimize tool deflection.

For production engineers, if he's designing a wood part, understanding these tool choices helps in designing features that are efficiently machinable.

What Factors Determine the Cost of Wood CNC Machining?

Budget is always a key consideration. What elements contribute to the overall price when you're looking to get custom wood parts made via CNC machining?

Costs depend on wood type and price, design complexity (machining time), quantity of parts (setup vs. run time), specific tooling needs, and any required finishing or assembly.

Diving Deeper into Cost Estimation

The cost of Wood CNC machining can vary widely, just like with metal machining. When an engineer like David requests a quote, several factors come into play. Understanding these can help in designing parts that are more cost-effective to produce.

-

Material Cost:

- The type of wood chosen significantly impacts cost. Exotic hardwoods will be much more expensive than common softwoods or standard MDF sheets. The thickness and overall volume of material needed are also direct cost drivers.

-

Design Complexity and Machining Time:

- This is a major factor. Highly intricate 2D designs or complex 3D carvings require more programming time and significantly longer machine run times. The more cutting paths, tool changes, and machine movements involved, the higher the cost.

- Features like deep pockets, very fine details, or undercuts (if achievable with specialized tooling) will add to the machining time.

-

Quantity of Parts:

- Setup Time: There's an initial setup cost for each job, which includes programming, machine setup, and material handling. For a single custom part or a very small batch, this setup cost is spread over fewer items, making the per-part cost higher.

- Run Time: For larger quantities, the setup cost is amortized, and the per-part cost decreases. The efficiency of CNC in producing multiple identical parts becomes more apparent.

-

Tooling Requirements:

- While standard wood CNC bits are common, a project might require specialized or custom-ground bits for unique profiles or materials, which can add to the cost. Tool wear, especially with abrasive materials like MDF, is also factored in over longer runs.

-

Finishing and Assembly:

- Does the part require sanding, painting, staining, lacquering, or assembly with other components after machining? These post-machining operations add labor and material costs.

-

Tolerance Requirements:

- While wood tolerances are generally looser than metal, if a design calls for unusually tight tolerances for wood, it might require more careful setup, slower machining, and more rigorous quality control, potentially increasing costs.

-

Nesting Efficiency:

- For parts cut from sheet goods, how efficiently the shapes can be "nested" (arranged) on the sheet to minimize waste will impact material cost.

By considering these factors during the design phase, David can often make choices that maintain functionality while optimizing for more cost-effective Wood CNC machining. For example, simplifying complex curves or standardizing hole sizes can reduce machining time.

How Can Allied Metal Assist with Your Wood CNC Machining Needs?

Allied Metal is known for metal and plastic CNC. Can we still help if your project involves Wood CNC machining, perhaps for prototypes or specialized components?

While our core is metal/plastic, we can assist with wood CNC for prototypes, jigs/fixtures, or by leveraging our CNC expertise for DFM advice and connecting you with specialized partners.

Diving Deeper into Our Wood-Related Capabilities

This is a fair question for David to ask. While Allied Metal's primary focus and deep expertise lie in the CNC machining of metals and engineering plastics, as well as 3D printing and rapid prototyping, our fundamental understanding of CNC principles, CAD/CAM software, and precision manufacturing is broadly applicable. My insight is that "CNC machining works great with wood," and we recognize its value.

Here’s how we can potentially assist with projects involving Wood CNC machining:

-

Prototyping in Wood:

- Before committing to expensive metal tooling or complex metal machining for a new design, creating functional or form-fit prototypes from wood (or engineered woods like MDF) can be a very cost-effective interim step. We can use our CNC capabilities to produce these wood prototypes quickly. This allows for early design validation and iteration.

-

Manufacturing Jigs, Fixtures, and Patterns:

- Wood and engineered woods are excellent materials for creating custom jigs and fixtures used in assembly or other manufacturing processes. We can CNC machine these aids to precise specifications.

- Similarly, master patterns for casting or vacuum forming can sometimes be effectively made from wood or MDF using CNC.

-

Design for Manufacturability (DFM) Advice:

- Even if the final part is wood and will be produced by a specialized wood CNC shop, our extensive DFM experience can be valuable. We can review designs for general CNC machinability, suggest ways to optimize for efficient cutting, or advise on material choices if the wood part interfaces with metal components we are also making.

-

Small-Batch Production of Specific Wood Components:

- If David's industrial automation systems require certain custom wood components – perhaps specialized mounting plates, insulating elements, or aesthetic panels that interface with metal structures – we might be able to produce these in smaller batches, especially if precision is key.

-

Project Integration and Partnering:

- For larger-scale or highly specialized Wood CNC machining projects that fall outside our direct day-to-day scope, we can leverage our industry network. We can help David connect with trusted, specialized wood CNC machining partners while potentially handling other metal or plastic components of his project, ensuring a well-integrated solution.

Our goal is always to provide the best overall manufacturing solution for our clients. If wood is the right material for a part of David's project, we want to help him realize that design effectively, either directly or through collaboration.

Conclusion

Wood CNC machining offers precision and versatility for diverse projects. Choosing the right wood, tools, and design approach ensures quality, efficiency, and cost-effectiveness for your specific needs.

-

Explore this link to understand the functionality and advantages of CNC routers in woodworking. ↩

-

Discover the importance of high-speed spindles in CNC machines for precision and efficiency in woodworking. ↩

-

Discover how CNC routers and mills can revolutionize your woodworking projects with advanced technology and precision. ↩

-

Learn about the benefits of MDF in CNC routing, including its uniformity and stability, making it a top choice for many applications. ↩

-

Discover the versatility of plywood in various applications, from structural components to cabinetry. ↩

-

Explore the benefits of MDF/HDF for woodworking projects, including their stability and smooth machining properties. ↩