EDITOR'S NOTE: Updated on October 16, 2025. We've added a detailed case study that delves into the actual cost structure of complex aerospace components, precisely revealing the cost of custom CNC parts.

Struggling to budget for custom parts with unpredictable quotes? Unexpected high costs can easily throw your project off track. Understanding the factors that influence pricing is key to getting accurate estimates.

The cost of custom CNC parts varies greatly. Simple parts in small batches might be $10-$50 each. However, complex designs or low quantities can push costs to $160 or more per part. Key drivers are design complexity, material choice, quantity, and required precision.

Getting a grip on CNC machining costs is essential before starting any project. Knowing what goes into the price helps you plan your budget effectively and prevents sticker shock when quotes arrive. Let's explore the details so you can make informed decisions.

What is the average cost of a custom CNC part?

Confused by wildly different quotes for CNC machining? Are high manufacturing costs eating into your project budget? Knowing the typical cost structure helps you plan better and negotiate more effectively.

There isn't a single "average" CNC cost. Pricing depends heavily on machine time, the material used, setup complexity, and programming effort. Simple projects might cost a few hundred dollars, while complex jobs requiring advanced machines can run into thousands.

Let's dive deeper into what makes up the cost.

Machine Hourly Rates

Rates depend on machine type (3-axis, 5-axis, lathe) and capabilities. Expect $50-$150+ per hour.

Material Impact

Costs vary significantly. Aluminum is often cost-effective, while steel, stainless steel, titanium, or high-performance plastics are more expensive.

Setup and Programming Time

These costs are more significant for small batches. Complex fixtures or intricate toolpaths increase this time.

I recall a client who was a designer himself and was surprised by the quote. Upon reviewing his design, we discovered that the complex mold core required 5-axis machining, which clearly explained why the machining time cost was higher than his previous simpler 3-axis parts.

How to calculate CNC machining costs?

Finding it hard to estimate your CNC project costs accurately? Worried about hidden fees or confusing quotes? Learning the basic calculation method helps you stay in control of your budget.

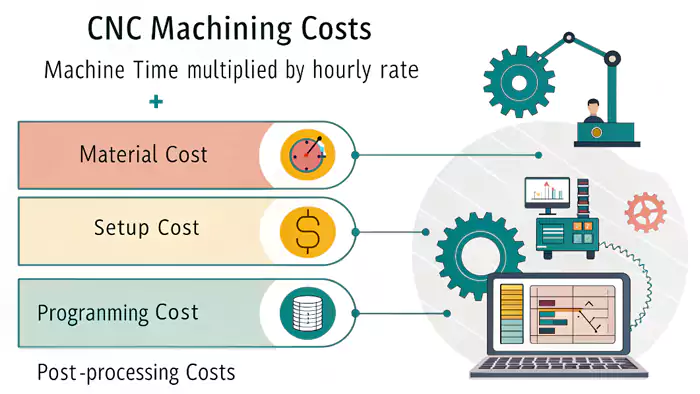

Calculate total cost by adding: (Machine Time × Hourly Rate) + Material Cost + Setup Cost + Programming Cost + Post-Processing Costs. Always ask potential suppliers for a detailed quote breaking down these elements.

Let’s break down how these costs add up.

Estimating Machine Time

Based on part geometry, features, material removal volume, and tolerance requirements. CAM software1 provides initial estimates.

Material Calculation

Based on the bounding box of the part plus extra for workholding and potential waste.

Setup and Programming Fees2

Often fixed per batch for setup. Programming can be hourly or fixed, depending on complexity.

Finishing Touches

Costs for deburring, tumbling, anodizing, plating, painting, etc., added separately if required.

I often help clients understand quotes by reviewing CAD files together. We identify features that impact machining time and explore whether simpler, more economical alternatives exist that maintain functionality.

How much is a CNC machine?

Considering bringing CNC machining capabilities in-house? Unsure about the level of investment required? Understanding machine prices helps you weigh the pros and cons against outsourcing.

CNC machine prices range dramatically. Small desktop or hobbyist CNC routers might start around $500-$5,000. Professional-grade, industrial 3-axis vertical mills typically cost $50,000-$150,000+, while advanced 5-axis machines can easily cost $200,000 to $500,000 or much more.

The price depends on many things.

Hobby vs. Industrial

Hobby machines are much cheaper but lack the rigidity, power, precision, and durability for production work.

Key Cost Drivers (Axes, Size, Brand)

More axes, larger work envelopes, higher precision specs, and reputable brands command higher prices.

Hidden Costs

Don't forget tooling, workholding fixtures, CAM software licenses, maintenance, coolant, electricity, and operator training – these add up.

How can I get custom CNC part?

Need a custom prototype or production part manufactured? Not sure about the process or where to begin? Getting your design CNC machined is straightforward if you follow a few key steps.

Finalize your 3D CAD model (STEP is a common format). Find a trusted CNC machining service provider, like Allied Metal. Submit your design files, specifying material, quantity, tolerances, finish, and deadline for a quote. Approve the quote to kick off production.

Here’s a typical workflow:

Design and File Prep

Create accurate 3D models3 (STEP, IGES). Provide 2D drawings for tolerances and specifications.

Choosing the Right Shop

Match shop capabilities (machines, materials, expertise) to your project needs. Check reviews/certifications.

The Quoting Process

Submit a detailed RFQ. Understand the quote breakdown (setup, material, machining, finishing).

From Order to Delivery

Shop confirms order, schedules production, machines parts, performs quality control, and ships to you.

Case Study: Cost Analysis of an Aerospace Mounting Bracket

Wondering how all these cost factors come together in a real project? Let me walk you through a recent aerospace bracket we machined - it's a perfect example of where the money actually goes.

We manufactured 50 units of a complex aluminum mounting bracket for an aerospace client, with the final cost breaking down to $187 per part. The project total was $9,350, with machine time accounting for 45% of the cost, material 25%, setup 15%, and finishing 15%.

An aerospace equipment supplier needed a critical mounting bracket for a new avionics system. The part had to be lightweight yet withstand significant vibration loads, requiring both complex geometry and precise tolerances.

Part Specifications & Requirements:

- Material: 7075-T6 Aluminum (chosen for strength-to-weight ratio)

- Dimensions: 150mm × 80mm × 25mm

- Quantity: 50 pieces

- Critical Features:

- 0.02mm positional tolerance on mounting holes

- 0.1mm true position on datum features

- Ra 1.6μm surface finish on mating surfaces

- 3mm minimum wall thickness throughout

- Lead Time: 4 weeks from order to delivery

Cost Breakdown Analysis:

| Cost Component | Amount | Percentage | Details |

|---|---|---|---|

| Material | $2,337 | 25% | 7075-T6 aluminum plate, 30% waste factor included |

| Machine Time | $4,208 | 45% | 18 hours total on 5-axis CNC at $75/hour |

| Setup & Programming | $1,402 | 15% | 2 hours programming + 4 setups at $150/setup |

| Finishing & QA | $1,403 | 15% | Anodizing, laser etching, full inspection report |

| Total Cost | $9,350 | 100% | $187 per part |

Technical Challenges & Cost Implications:

-

Complex 3D Contouring: The aerodynamic shape required 5-axis simultaneous machining, doubling the machine time compared to 3-axis processing.

-

Thin-Wall Machining: Maintaining 3mm walls across large spans demanded specialized tooling and reduced feed rates to prevent vibration and ensure dimensional stability.

-

High-Precision Features: The 0.02mm hole tolerances required jig boring and in-process verification, adding 2 hours to the programming and 30 minutes per part to the machining time.

The production manager noted: "Seeing the detailed breakdown helped us understand why this part cost what it did. The 5-axis machining was essential for the complex curves, and the material choice was driven by performance requirements. What looked like a simple bracket on the surface turned out to be quite engineering-intensive."

Ready to Get Transparent Pricing on Your CNC Project?

As this case shows, understanding exactly what drives CNC machining costs helps you make smarter decisions about your designs and budgets. At Allied Metal, we believe in complete cost transparency - you'll always know where every dollar goes in your quote.

Our manufacturing experts can help you:

- Optimize designs for cost-effectiveness without compromising function

- Select the right materials and processes for your specific application

- Balance quality requirements with budget constraints

- Deliver precision parts on time, from prototype to production

Leverage our expertise and get a detailed quote for your CNC machining services.

We'll analyze your CAD files for material selection, design optimization, and provide transparent pricing—all within 24 hours.

How to reduce the cost of custom CNC parts?

Are CNC machining costs impacting your project's bottom line? Looking for ways to reduce manufacturing expenses without sacrificing quality? Smart design choices and careful planning can significantly lower your costs.

Simplify your design by avoiding deep pockets, very thin walls, and complex curves where possible. Choose standard, easy-to-machine materials like Aluminum 6061. Loosen tolerances on non-critical features. Increase order quantity to benefit from economies of scale.

Let's explore how to cut costs effectively through Design for Manufacturability (DFM).

Design Optimization (DFM)

| Cost Reduction Tip | How it Helps | Example |

|---|---|---|

| Simplify Design | Reduces machine time, tool changes | Use standard hole sizes, avoid deep pockets |

| Allow Corner Radii | Allows larger, faster tools | Specify internal radii instead of sharp corners |

| Reduce Setups | Lowers setup time/cost | Design features accessible from one or two sides |

| Thicken Thin Walls | Prevents vibration, allows faster machining | Minimum wall thickness (e.g., > 1mm for metals) |

Smart Material Choices

Use Aluminum 60614, 1018 Steel, or Acetal (Delrin) when possible. They machine quickly and are less expensive.

Tolerance Strategy

Specify tight tolerances5 only on critical features. Use looser default tolerances elsewhere.

Volume Benefits

Setup costs are amortized. Higher quantities = lower unit price. Consider ordering spares or future needs together.

Conclusion

Understanding CNC cost drivers like design, material, and quantity empowers you. Optimize your parts, choose materials wisely, and communicate clearly with your machining partner for cost-effective, quality results.

-

Explore this link to understand how CAM software can optimize your manufacturing process and cost estimation. ↩

-

Learn about setup and programming fees to better manage your production costs and improve budgeting strategies. ↩

-

Explore this link to learn about the latest techniques and tools for creating precise 3D models, essential for successful projects. ↩

-

Explore the advantages of Aluminum 6061, including its machinability and cost-effectiveness, to enhance your material selection process. ↩

-

Understanding the significance of tight tolerances can help improve product quality and performance in critical applications. ↩