Table of Contents:

CNC Machining Customization: The Future of Custom Manufacturing

- February 7, 2025

- Tony

- Last updated October 21, 2025 by Lucy

1. CNC machining customization

What is CNC machining customization?

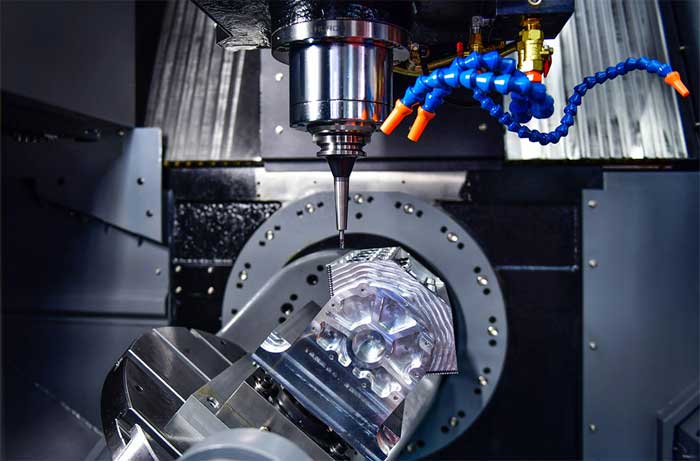

CNC machining customization is a type of machining that utilizes computer numerical control (CNC) to control machine tools to machine a variety of materials according to customer requirements accurately.

CNC machine tools allow designers to enter precise digitized drawings and instructions to automate complex machining processes such as cutting, milling, turning, etc. in order to create parts that meet specific specifications.

2. Advantages of customized CNC machining

Precision and consistency are crucial in industries like aerospace and medical. CNC machining delivers high accuracy by following digital instructions. It ensures every part meets strict quality standards.

Customized CNC machining offers precision, flexibility, and efficiency. It produces accurate, consistent parts tailored to specific needs. The process supports various materials, reduces waste, and speeds up production. This makes it ideal for complex designs and quick turnaround projects.

Precision and Consistency:

CNC machining ensures high accuracy and consistent quality by following precise digital instructions, which is essential for industries like aerospace, medical, and automotive.

Custom CNC Machining Solutions :

It allows for tailored parts that meet specific customer needs, from complex geometries to unique material requirements, offering a flexible approach to customization.

Boosted Efficiency:

With automation, CNC machining significantly improves productivity, shortens production cycles, and reduces labor costs, enabling faster responses to market demands.

Material Versatility:

This method accommodates a wide range of materials, including metals , plastics , and composites, ensuring that companies can choose the right material while maintaining performance.

Cost Reduction:

By minimizing waste and preventing excess inventory in small batches, CNC machining helps reduce overall production costs and increases efficiency.

Complex Designs Made Easy:

CNC machining can produce intricate shapes and multifunctional parts that traditional methods struggle to achieve, addressing modern industrial needs for high-performance products.

Quick Turnaround:

Thanks to advanced automation, CNC machining reduces lead times, allowing businesses to receive custom parts faster and accelerate product launches.

3. Common application areas for customized CNC machining

Customized CNC machining serves many industries. It produces parts with high accuracy and reliability. Here are some typical applications.

CNC machining is used in automotive, medical, aerospace, and industrial equipment. It makes engine components, medical devices, aircraft parts, and mechanical systems. The process ensures durability, precision, and performance in critical applications.

In the automotive industry, CNC machining creates engine parts and transmission systems . It ensures durability and high performance. Medical equipment requires extreme precision. CNC produces reliable devices that meet strict standards.

Aerospace components face extreme conditions. CNC machining makes high-strength, lightweight parts . These are essential for aircraft safety. Industrial equipment uses CNC for pumps, valves, and mechanical components. It meets diverse sector needs.

Case Study: Custom High-Precision Aerospace Bracket

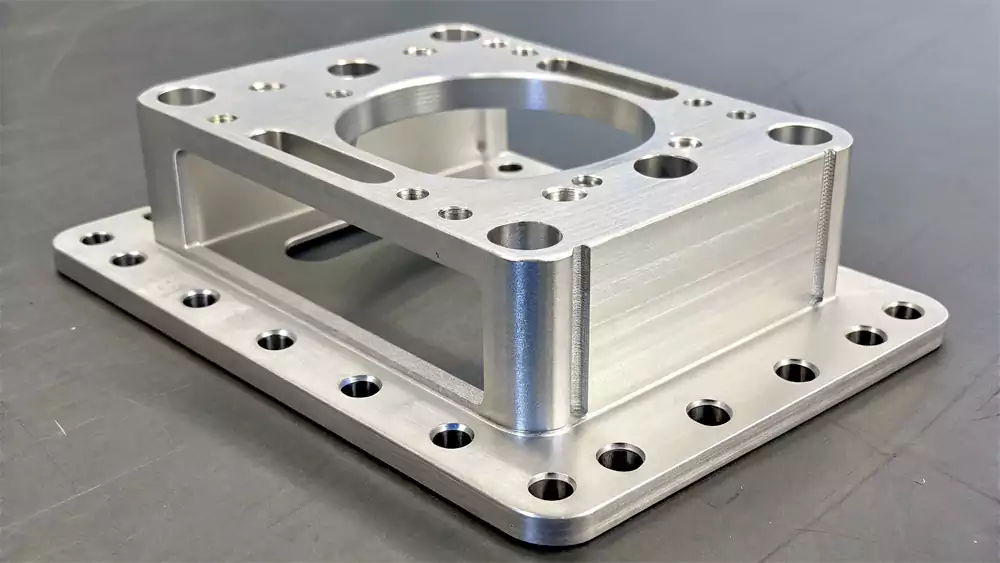

We recently worked on a project for a satellite communication system. The client needed a mounting bracket with extreme precision. The part had to withstand vibration and thermal changes.

The bracket was made from Aluminum 7075-T6 . Dimensions were 150mm in length, 75mm in width, and 25mm in height. Critical bore diameters required tolerances of ±0.005mm. Surface finish specifications were 0.8 μm Ra. Post-processing included Type II anodizing per MIL-A-8625 for corrosion resistance. We produced 50 pieces for the order.

The main challenge was maintaining dimensional stability on thin walls as fine as 1.5mm. Our solution used 5-axis CNC milling with adaptive toolpaths. We implemented in-process coordinate measuring machine (CMM) inspection. This ensured each part met specifications before completion.

The result was successful. All brackets passed quality checks with a first-pass yield of 98%. The client confirmed perfect fit in their assembly. This reduced their project timeline by two weeks.

4. How to choose the right CNC machining customization service provider?

Selecting a reliable provider is critical for project success. You need a partner with technical expertise and quality systems. Here are key factors to consider.

Choose a provider with proven experience and technical skills. They should handle complex designs and deliver high-quality parts. Look for material versatility, a strong quality management system , and on-time delivery capability.

Experience and technical competence ensure your needs are met. A skilled provider can manage intricate designs and material challenges. They use advanced equipment to achieve precision.

Material selection capabilities are important. A good provider works with metals, plastics, and alloys. They help pick the right material for your application. Quality management and delivery reliability prevent delays. Check for certifications like ISO 9001 to verify their standards.

5. Overview of the CNC machining customization process

1. Clarifying Requirements

First, the customer’s needs are discussed, including function, size, material, and accuracy. Drawings or specifications are provided.

2. Design and Engineering

Engineers create a design using CAD software and assess the part’s machinability and material choice.

3. Programming

Next, engineers generate the CNC machine program (G-code) using CAM software to ensure accuracy. Simulations may also be run to check for potential issues.

4. Preparation

Raw materials are selected and cut to size, and CNC machines are set up and calibrated.

5. Machining

The CNC machine performs cutting, turning, and milling operations to shape the part according to the design.

6. Quality Check

Once machining is complete, parts are inspected for size, finish, and accuracy. Adjustments are made if necessary.

7. Post-Processing

If needed, parts undergo treatments like heat treatment, plating, or painting to improve strength or appearance.

8. Packaging and Delivery

Finished parts are cleaned, packaged, and shipped with a quality report.

6. Challenges and solutions for customization of CNC machining

Despite the many advantages of customized CNC machining, there are some challenges to be faced in practice:

Complex Design and Accuracy Issues

Some customized parts may involve complex geometries or high precision requirements, which require the use of high-end CNC equipment and professional technicians to ensure machining accuracy.

Cost control and optimization

Customized machining tends to be costly, especially in small production runs. To reduce costs, efficient production can be achieved by choosing the right materials and optimizing the machining process.

7. Summary

Customized CNC machining meets the modern manufacturing industry’s needs for high precision, efficiency, and flexibility. It enables industries to achieve personalized customization. By selecting the right service provider and understanding the process and benefits, businesses can gain a competitive edge and drive product innovation and quality improvement.

As technology advances, CNC machining customization will become even more widespread, playing a key role in the future of manufacturing across various industries.