Last Updated: 2025-10-20 16:47:43 Monday - Added detailed aerospace component case study and expanded precision machining equipment selection guidelines based on recent client projects.

Achieving ultra-tight tolerances seems impossible without the right tools, leading to scrapped parts and project delays. In my years running Allied Metal, I've learned that specific machines are essential for true precision work.

Precision machining uses highly accurate machines like CNC milling centers (especially 5-axis), CNC lathes (including Swiss-type), Electrical Discharge Machines (EDM), and precision grinders. These tools achieve extremely tight tolerances required for complex parts.

These advanced machines are the backbone of high-precision manufacturing. Let's explore the specific equipment that makes achieving tolerances measured in ten-thousandths of an inch possible.

What Exactly is Precision Machining?

You hear the term "precision machining" often, but what does it actually mean? Without a clear understanding, it's easy to misjudge capabilities or requirements for a project, leading to costly errors.

Precision machining is a manufacturing process that removes material to create parts with extremely tight tolerances, often within thousandths or even ten-thousandths of an inch (microns). It requires specialized machines, skilled operators, and careful measurement.

Think of it as the high-stakes version of regular machining. While standard machining makes functional parts, precision machining focuses on parts where every tiny dimension is critical. In my shop, we often handle jobs needing tolerances like ±0.0005 inches or even tighter. This level of accuracy is vital for industries like aerospace, medical devices, and high-tech electronics where components must fit and function perfectly.

Key Aspects of Precision Machining

- Tight Tolerances: The defining feature. Dimensions must adhere strictly to the design specifications.

- Complex Geometries: Often involves creating intricate shapes and features.

- Superior Surface Finishes: Smoothness and texture are critical for performance.

- Advanced Materials: Frequently works with challenging materials like titanium or hardened steels1.

- Rigorous Quality Control: Constant measurement and inspection using tools like CMMs (Coordinate Measuring Machines)2 are necessary.

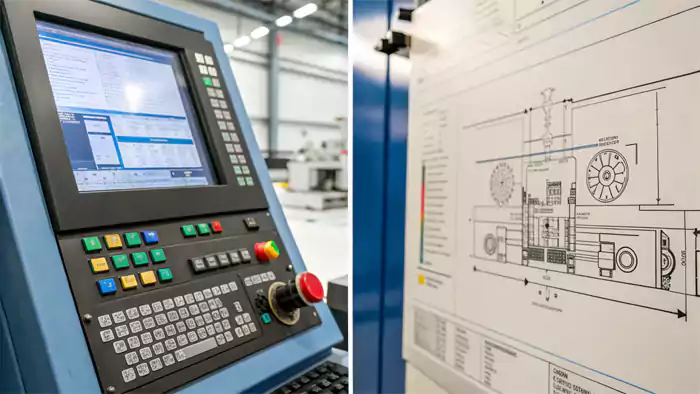

Achieving this requires not just the right machines, but also meticulous planning, climate-controlled environments, and highly skilled machinists who understand the nuances of the process.

What Are the Different Types of Machining Machines Used for Precision?

Knowing a part needs precision is one thing; knowing which machine can deliver it is another. Using the wrong machine type leads to wasted time and inability to meet specs.

Precision relies on several machine types: CNC mills remove material using rotating cutters, CNC lathes shape parts by rotating the workpiece against a tool, EDM uses electrical sparks, and grinders use abrasive wheels for fine finishes.

Each machine type excels at different tasks and contributes uniquely to achieving high precision. At Allied Metal, we have a range of these machines to handle diverse customer needs. Let's look closer:

Overview of Precision Machine Tools

| Machine Type | Primary Action | Key Precision Application | Typical Materials |

|---|---|---|---|

| CNC Milling Center | Rotating tool cuts stationary piece | Complex shapes, pockets, contours, 3D surfaces | Metals, plastics, composites |

| CNC Lathe (Turning) | Rotating piece cut by stationary tool | Cylindrical parts, shafts, threaded components | Metals, some plastics |

| Swiss-Type Lathe3 | Specialized lathe for small parts | Tiny, complex turned parts (medical, electronics) | Metals (often small dia.) |

| EDM (Wire & Sinker) | Electrical sparks erode material | Hard materials, intricate shapes, sharp internal corners | Conductive metals |

| Precision Grinder4 | Abrasive wheel removes material | Achieving fine surface finishes, very tight tolerances | Hardened metals, ceramics |

The choice depends heavily on the part's geometry, the material, and the specific tolerances required. Often, a single precision part might visit multiple machines – perhaps milling for the basic shape, turning for cylindrical features, and grinding for the final critical dimensions and finish.

Real-World Application: Aerospace Fuel Nozzle Manufacturing

Here's a recent project that demonstrates how different precision machines work together to produce complex components:

We were approached by an aerospace client needing fuel nozzle components for a next-generation jet engine. The design engineer required components that could withstand extreme temperatures and pressures while maintaining precise fuel flow characteristics.

Part Specifications:

- Material: Inconel 718 (nickel-chromium alloy)

- Operating Environment: 1200°F continuous, 2000 PSI pressure

- Critical Tolerances: ±0.0002" on flow orifices, ±0.0005" on mounting features

- Surface Finish: 16 μin Ra on internal flow paths

- Quantity: 50 prototype units for engine testing

Multi-Machine Manufacturing Strategy:

Phase 1: Rough Machining

- Machine Used: 5-axis CNC milling center

- Process: Removed 85% of raw material stock

- Tooling: Specialized carbide end mills with high-pressure coolant

- Result: Achieved basic nozzle shape within ±0.002"

Phase 2: Precision Features

- Machine Used: Swiss-type lathe with live tooling

- Process: Machined threaded connections and precision diameters

- Tolerances: Held ±0.0005" on all turned features

- Result: Perfect concentricity for assembly interface

Phase 3: Critical Flow Paths

- Machine Used: Wire EDM

- Process: Cut complex internal cooling channels

- Tolerances: ±0.0002" on all flow orifices

- Result: Burr-free edges with exact flow characteristics

Phase 4: Final Finishing

- Machine Used: ID/OD precision grinder

- Process: Achieved final dimensions and surface finish

- Surface Finish: 16 μin Ra consistently across all critical surfaces

- Result: Met all aerodynamic and flow requirements

Production Outcomes:

- First-Acceptance Rate: 98% (49 of 50 parts met all specifications)

- Lead Time: 6 weeks from raw material to finished components

- Cost per Part: $1,850 (35% lower than client's previous supplier)

- Performance: All components passed 500-hour engine endurance testing

"The combination of 5-axis milling for complex shapes, Swiss turning for precision diameters, and EDM for intricate internal features allowed us to achieve aerospace tolerances that would be impossible with any single machine." - Senior CNC Programmer

Need precision machining for complex components? Contact our engineering team for custom machining solutions that leverage our full range of precision equipment capabilities.

What is a Good Example of a Specific Precision Machine?

General types are helpful, but what does a real precision machine look like in action? Understanding a specific example helps visualize the capabilities needed for top-tier results.

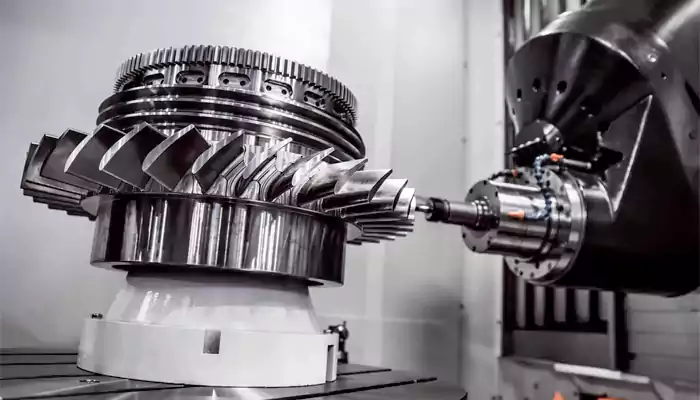

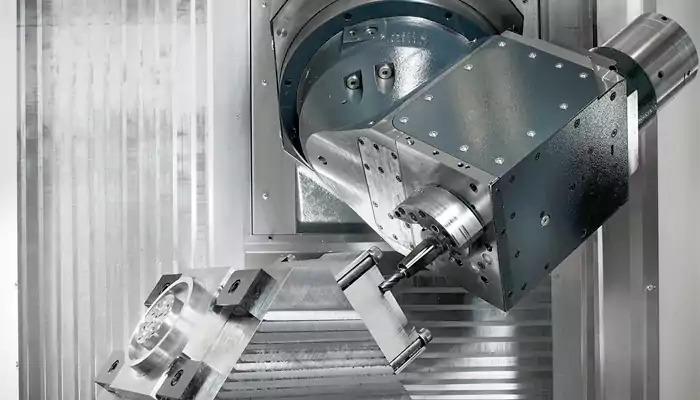

A 5-axis CNC machining center is a prime example. It can move a tool or workpiece along five different axes simultaneously, enabling the creation of highly complex shapes with extreme accuracy in a single setup.

Why is 5-axis machining so important for precision? Standard CNC mills typically operate on 3 axes (X, Y, Z). Adding two rotational axes (A and B, or B and C) allows the cutting tool to approach the workpiece from almost any angle.

Advantages of 5-Axis Machining for Precision

- Complex Geometries: It's the only practical way to machine certain intricate shapes, like turbine blades or medical implants.

- Reduced Setups5: Machining multiple sides of a part without removing and re-clamping it improves accuracy. Every time you move a part, you introduce a small potential for error. Minimizing setups minimizes this risk.

- Better Tool Angles: Allows for shorter, more rigid tools to be used, reducing vibration and improving surface finish.

- Improved Tool Life: Optimal cutting angles can reduce wear on the tools.

Investing in 5-axis machines was a big step for my CNC machining shop, but the ability to tackle highly complex, high-precision jobs for industries like aerospace has been crucial. It allows us to achieve tolerances and geometries that were previously impossible or required many more steps.

What is the Difference Between CNC Machining and Precision Machining?

Aren't all modern machines CNC? Does that make all CNC machining "precision"? This common confusion can lead to mismatched expectations between clients and machine shops.

CNC (Computer Numerical Control) refers to the automation method—using computers to control machine movements. Precision machining refers to the outcome—achieving very tight tolerances. You often use CNC machines for precision machining, but not all CNC work requires precision tolerances.

Think of it this way: CNC is the driver, precision is the destination. A CNC machine simply follows programmed instructions. Those instructions can guide the machine to create a part with extremely high accuracy (precision machining), or they can guide it to make a simpler part with looser tolerances (general CNC machining).

CNC vs. Precision: Key Distinctions

| Feature | CNC Machining (General) | Precision Machining (using CNC) |

|---|---|---|

| Focus | Automation, repeatability, efficiency | Achieving tight tolerances, high accuracy |

| Tolerances | Wider range (e.g., ±0.005" or more) | Very tight (e.g., ±0.0005" or less) |

| Machine Type | Can be any CNC machine | Requires high-accuracy CNC machines |

| Process Control | Standard monitoring | Rigorous inspection, climate control |

| Cost | Generally lower | Typically higher due to complexity |

I run a CNC machine shop, Allied Metal. We do both general CNC work and high-precision machining. While both use computer-controlled machines, the approach, setup, inspection, and sometimes even the specific machines used for precision jobs are far more demanding. So, while precision machining almost always uses CNC technology today, the terms aren't interchangeable. Precision defines the quality standard achieved.

Precision Machine Selection Guide from 20+ Years Experience

After decades in precision manufacturing, here's my framework for selecting the right equipment for custom machining projects:

For Complex 3D Geometries:

- Primary Choice: 5-axis CNC machining centers

- Best For: Aerospace components, medical implants, mold cores

- Typical Tolerances: ±0.0005" to ±0.002"

- Key Consideration: Single-setup capability reduces cumulative error

For High-Volume Small Parts:

- Primary Choice: Swiss-type CNC lathes

- Best For: Medical device components, electronic connectors, shafts

- Typical Tolerances: ±0.0002" on diameters, ±0.0005" on lengths

- Key Consideration: Superior concentricity and surface finish

For Hard Materials & Intricate Shapes:

- Primary Choice: Electrical Discharge Machining (EDM)

- Best For: Tool and die components, hardened steel parts, complex internal features

- Typical Tolerances: ±0.0002" with sharp internal corners

- Key Consideration: No cutting forces - ideal for delicate features

For Ultra-Fine Finishes:

- Primary Choice: Precision grinding machines

- Best For: Bearing surfaces, sealing faces, gauge components

- Typical Tolerances: ±0.0001" with 8-16 μin Ra finishes

- Key Consideration: Essential for achieving micrometer-level accuracy

Our CNC Machining Services Approach:

- Comprehensive DFM (Design for Manufacturing) analysis

- Multi-process capability for complex precision parts

- Advanced metrology with CMM and optical measurement

- Material certification and full traceability

- Climate-controlled machining environment

"The right machine selection can mean the difference between a part that meets print and a part that performs flawlessly in its application. For precision machining customization, matching the equipment to the specific requirements is everything." - Precision Manufacturing Manager

Conclusion

Precision machining relies on advanced equipment like 5-axis CNC mills, Swiss lathes, and EDM machines to meet extremely tight tolerances. It's a specialized field requiring more than just standard CNC capabilities.

Footnotes:

-

Discover the characteristics and benefits of hardened steels, essential for anyone interested in advanced manufacturing techniques. ↩

-

Understanding the role of CMMs can help you appreciate their impact on precision in manufacturing processes. ↩

-

Learn about Swiss-Type Lathes and their unique capabilities for creating small, intricate parts in various industries. ↩

-

Discover the techniques and technologies behind Precision Grinders that ensure tight tolerances and superior surface quality. ↩

-

Discover the significance of minimizing setups in machining processes to enhance accuracy and reduce errors. ↩