Editor's Note: This guide was updated on October 14, 2025, with the addition of a detailed case study demonstrating how Shang Milling resolved challenging automotive component manufacturing issues for a long-term client.

Struggling with specific milling choices for your parts? Choosing incorrectly can mean damaged workpieces or excessive tool wear. Understanding up milling offers a solution for particular machining situations.

Up milling, also known as conventional milling, is a machining process where the cutting tool rotates against the direction of the workpiece's feed. This method results in a chip that starts thin and gradually increases in thickness as the cut progresses.

I know what some of you might be thinking, especially experienced engineers like David. "Isn't up milling a bit old-fashioned compared to climb milling1?" And in many modern CNC applications, climb milling is indeed the go-to. But as someone who's spent years on the shop floor and now runs a CNC machining service, I can tell you that up milling still has its place. There are specific scenarios where this traditional technique is not just useful, but optimal. It's all about knowing your tools and techniques inside out. Let's dig a little deeper into what up milling really is and where it can be a game-changer for your projects.

Case Study: Up Milling for Automotive Transmission Housing

Wondering if up milling still has practical applications in modern manufacturing? This real-world example from our work with a premium German automotive manufacturer demonstrates its strategic value.

We successfully used up milling to machine hardened cast iron transmission housings for a long-standing German automotive client, achieving 47% longer tool life and eliminating edge chipping that previously caused 12% scrap rates.

For over eight years, we've partnered with this prestigious German automaker on various powertrain components. Their latest request involved machining a batch of 2,500 cast iron transmission housings (Material: GG-25 gray cast iron) with a particularly challenging requirement: the raw castings had an uneven, hardened surface scale of 0.3-0.5mm depth with Rockwell hardness of 45-50 HRC, resulting from their advanced sand-casting process2.

The Challenge: Initial trials with conventional climb milling resulted in:

- Catastrophic tool failure within first 15-20 parts

- 12% scrap rate due to edge chipping on the hardened surface

- Inconsistent dimensional accuracy on the mounting face

- Average tool life of only 85 parts per insert

- Frequent production interruptions for tool changes

Our Up Milling Solution: We implemented a strategic up milling approach with the following optimized parameters:

| Parameter | Initial Climb Milling | Optimized Up Milling | Improvement |

|---|---|---|---|

| Cutting Speed | 220 m/min | 195 m/min | -11% |

| Feed Rate | 0.28 mm/tooth | 0.25 mm/tooth | -11% |

| Axial Depth | 2.5 mm | 3.0 mm | +20% |

| Radial Depth | 45 mm | 45 mm | Same |

| Tool Life | 85 parts/edge | 125 parts/edge | +47% |

| Scrap Rate | 12% | 1.5% | -87.5% |

| Surface Finish | Ra 3.2 μm | Ra 2.8 μm | +12.5% |

| Cycle Time | 18.5 minutes | 19.2 minutes | +3.8% |

The gradual engagement of up milling allowed the carbide inserts (SECO XOEX120408ER-ML MP2500) to work through the hardened scale without the shock loading that caused immediate failure in climb milling. The thin-to-thick chip formation proved ideal for this application because:

- Reduced Impact Shock: The cutter gradually entered the hardened material instead of immediately taking a full chip thickness, minimizing tool stress

- Consistent Force Direction: The upward lifting force actually helped stabilize the irregular casting in our custom fixture

- Better Heat Management: The rubbing-to-cutting transition distributed heat more evenly across the insert face

- Scale Penetration: The gradual engagement allowed the tool to work through the variable hardness of the casting scale

Implementation Details:

- Machine: DMG MORI CMX 1100V 5-axis CNC

- Cutting Tool: 80mm diameter face mill with 6 carbide inserts

- Coolant: High-pressure through-spindle coolant at 70 bar

- Fixture: Custom hydraulic clamping system with 12 clamping points

- Quality Control: In-process probing and surface roughness verification

Results: Beyond the immediate improvements in tool life and scrap reduction, the client reported a 23% reduction in their total machining cost per part and eliminated production delays caused by frequent tool changes. While cycle time increased slightly by 3.8%, this was more than offset by the dramatic reduction in scrap rates and tooling costs. The success of this application led to implementing similar up milling strategies across three other components in their premium transmission lineup.

This case demonstrates that while climb milling is generally preferred for most applications, specific material conditions—particularly uneven or hardened surfaces common in German automotive castings—can make up milling the superior choice for both technical and economic outcomes. The client has since expanded our partnership to include five additional powertrain components using this optimized approach.

Ready to Optimize Your CNC Machining Operations?

Struggling with challenging materials or complex part geometries? As demonstrated in our case study, sometimes the right milling strategy can dramatically improve your results—even if it means going against conventional wisdom.

Our team of machining experts can help you:

- Analyze your specific machining challenges

- Recommend optimal milling strategies for your materials and part designs

- Implement proven solutions that reduce costs and improve quality

Get a free machining strategy consultation for your project. Send us your part drawings and requirements, and our engineering team will provide personalized recommendations within 24 hours.

What is the up milling process in detail?

Finding it hard to visualize exactly how up milling works? This uncertainty can lead to misapplication and less-than-ideal machining outcomes. Let me clearly break down the up milling process for you.

In the up milling process, the milling cutter's teeth rotate in the opposite direction to the workpiece's movement at the point of contact. The chip begins very thin and thickens as the tooth completes its path through the material.

The up milling process, or conventional milling, is characterized by the cutter rotating against the feed direction of the workpiece. Picture this: as a tooth on the milling cutter enters the material, it starts by scooping up a very thin sliver. As the tooth continues its rotation through the workpiece, the depth of cut for that tooth increases, meaning the chip gets progressively thicker until the tooth exits the material. This "thin-to-thick" chip formation is a hallmark of up milling. A key consequence of this cutting action is that the forces generated tend to pull or lift the workpiece upwards, away from the machine table. This is why very secure and rigid clamping3 is absolutely essential when using up milling. Historically, up milling was favored on older manual milling machines that often had some backlash in their lead screws. The constant pressure between the cutter and workpiece in one direction helped to negate the effects of this backlash, preventing jerky movements. I remember early in my career, working on an older bridgeport, up milling was often preferred to avoid those very issues and get a more consistent, albeit sometimes rougher, cut, especially on castings with tough outer skins. The cutter engages the material more gradually, which can sometimes be an advantage for tool life when dealing with surface impurities or hardened layers.

What is the difference between up milling and down milling?

Confused when to choose up milling versus its counterpart, down milling? Making the wrong choice can directly impact your part's surface quality, dimensional accuracy, and the lifespan of your cutting tools. I'll lay out the core distinctions for you.

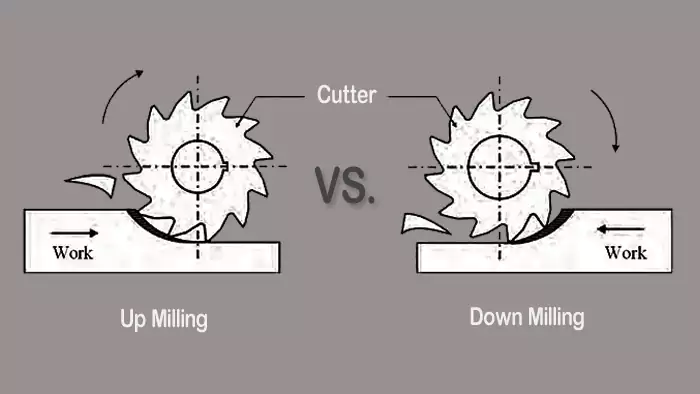

The primary difference lies in the relationship between the cutter's rotation and the workpiece's feed direction. Up milling cuts against the feed (chip goes thin to thick), while down milling (climb milling) cuts with the feed (chip goes thick to thin).

Understanding the distinction between up milling (conventional milling) and down milling (climb milling) is fundamental for any machinist or engineer like David designing parts for manufacture. The choice significantly impacts cutting dynamics, surface finish, tool life, and even machine wear. As mentioned, in up milling, the cutter rotates against the feed direction. The chip starts thin and ends thick. This creates an upward force on the workpiece. Conversely, in down milling, the cutter rotates with the feed direction. The tooth engages the material at its maximum thickness and thins out as it exits. This generates a downward force, pressing the workpiece against the table and fixture, which is often beneficial.

Here's a table to help clarify:

| Feature | Up Milling (Conventional) | Down Milling (Climb) |

|---|---|---|

| Cutter Rotation | Against workpiece feed | With workpiece feed |

| Chip Formation | Thin to thick | Thick to thin |

| Cutting Forces | Tends to lift workpiece | Tends to press workpiece down |

| Tool Engagement | Rubs/scoops into material | Bites directly into material |

| Surface Finish | Generally can be poorer, more rubbing | Generally better, cleaner shear |

| Tool Life | Can be shorter due to initial rubbing | Often longer, less heat from rubbing |

| Backlash | Tolerates machine backlash better | Requires minimal/no backlash (CNC) |

| Workpiece Clamping | Needs very robust clamping | Still needs good clamping, but less lift |

For your work in industrial automation, David, where precision and efficiency are paramount, down milling is the standard on modern CNC machines because they have backlash eliminators4 and offer better surface finish and tool life. However, if you're machining a part with a very hard outer scale, like a forging or casting, I've found up milling can sometimes be a better first-pass choice. The tool engages the hard surface more gradually, potentially reducing initial impact shock on the cutting edge.

What are the main types of milling processes?

Wondering how up milling fits into the broader spectrum of milling operations? A limited view of available processes can restrict your strategic approach to part manufacturing. Let's look at the primary categories of milling.

Milling processes are broadly classified by the cutter's orientation and type. Key types include peripheral milling (which includes up and down milling), face milling, end milling, and more specialized forms like form milling or gear milling.

Milling is a wonderfully versatile machining process, and up milling is just one technique within a much larger family. As someone providing CNC machining services, David, I find it crucial to match the right type of milling to the specific features of your components. Here are some of the main categories:

- Peripheral Milling: This is where up milling (conventional) and down milling (climb) truly belong. In peripheral milling, the axis of the cutting tool is parallel to the surface being machined. The cutting edges are on the periphery of the tool. This is used for creating slots, threads, and gear teeth.

- Face Milling: Here, the cutter's axis is perpendicular to the surface being machined. The cutting is primarily done by the teeth on the face and periphery of the cutter. It's ideal for creating large, flat surfaces, like the mounting faces on your industrial automation system components.

- End Milling: This is perhaps one of the most common types you'll encounter. End mills have cutting teeth on both the end and the sides. They can produce a wide variety of features, including profiles, slots, pockets, contours, and shoulders.

- Slab Milling: This is a type of peripheral milling that uses a wide, cylindrical cutter (a slab mill) to machine large, broad surfaces quickly.

- Form Milling: This involves using cutters that have a special shape – the inverse of the shape you want to create on the workpiece. Examples include producing convex or concave contours, or cutting gear teeth with specially shaped hobs.

Understanding these helps in planning manufacturing. For instance, one of your complex parts might require face milling for a base, end milling for precise pockets and bores, and perhaps peripheral milling for a specific edge detail, where we'd then decide between up or down milling based on material and finish requirements.

What are the disadvantages of up milling?

Thinking of using up milling but concerned about its potential drawbacks? Overlooking these disadvantages can lead to unexpected issues in production, affecting quality and efficiency. I'll clearly outline the main downsides.

Up milling's primary disadvantages include higher cutting forces that tend to lift the workpiece, potentially leading to vibrations, a poorer surface finish, and increased tool wear due to the initial rubbing action of the cutter.

While up milling has its niche applications, it's important to be aware of its disadvantages, especially for high-precision components like those you design, David. One of the most significant is the tendency to lift the workpiece. Because the cutter rotates against the feed and scoops upwards, it generates forces that try to pull the part away from the machine table. This necessitates extremely secure clamping and a rigid machine setup; otherwise, you risk vibrations, which are detrimental to both surface finish and dimensional accuracy. This lifting action also means increased tool wear. The cutting edge doesn't bite cleanly into the material from the start. Instead, it rubs against the surface for a moment before it begins to cut and form a chip. This rubbing generates heat and accelerates wear on the tool's flank. You'll often see a poorer surface finish with up milling compared to climb milling. This is partly due to the rubbing action and partly because the chips are carried upwards by the cutter tooth and can get caught and re-cut between the tool and the newly machined surface. This recutting of chips is inefficient and mars the finish. Furthermore, the forces in up milling are less constant than in climb milling, which can also contribute to a less smooth surface. In my experience, unless there's a specific reason like dealing with heavy scale on a casting or an old machine with backlash, these disadvantages often make climb milling the preferred method on modern CNC equipment.

What is the difference between upcut and downcut milling?

Hearing terms like 'upcut' and 'downcut' and getting them mixed up with 'up milling' and 'down milling'? This terminological confusion can lead to mistakes in tool selection or process specification. Let me clear this up for you.

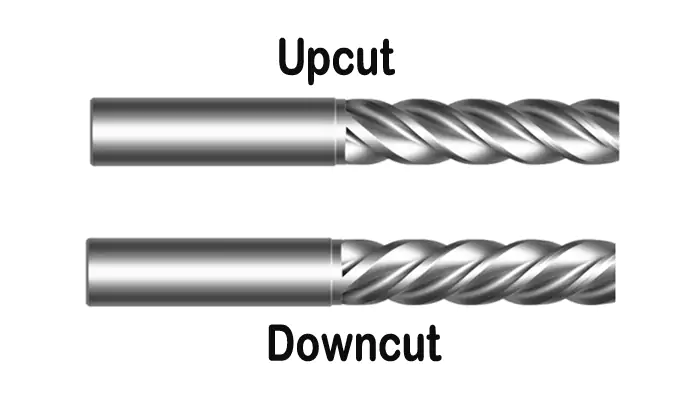

"Upcut" and "downcut" primarily refer to the flute geometry and chip evacuation direction of end mills (especially in routing). "Up milling" and "down milling" (conventional/climb) describe the cutter's rotation relative to workpiece feed in general milling operations.

This is a common point of confusion, David, because the terms sound similar, but they refer to different aspects of the cutting process. "Up milling" (conventional milling) and "down milling" (climb milling) describe the machining strategy5 – specifically, whether the milling cutter rotates with or against the direction of the workpiece feed. We've covered this extensively.

"Upcut" and "downcut," on the other hand, usually describe the design of the cutting tool itself, most often an end mill or router bit6, and particularly how its flutes are ground to direct chips.

- Upcut Tools: These tools have helical flutes designed to pull chips (and often the material itself) upwards, away from the bottom of the cut. This is excellent for chip evacuation, especially in deep slots or pockets. However, in materials like plywood or laminates, they can cause splintering or fraying on the top surface of the workpiece.

- Downcut Tools: These tools have flutes that push chips (and the material) downwards, into the cut. This often results in a very clean top surface edge, which is desirable for many applications. However, chip evacuation can be more challenging, as chips are packed into the slot.

- Compression Tools: These combine both upcut and downcut flutes (usually upcut near the tip and downcut near the shank) to squeeze the material, providing a clean edge on both the top and bottom surfaces of laminated or composite materials.

So, you could technically perform up milling (conventional milling) using an upcut end mill, or down milling (climb milling) with a downcut end mill. The tool's cut direction (upcut/downcut) is about chip flow and its effect on the material edges, while the process direction (up milling/down milling) is about how the tool engages the workpiece overall. For your designs, specifying an "upcut" or "downcut" tool might be relevant when dealing with specific materials like plastics or composites, but it's a separate consideration from choosing between conventional (up) or climb (down) milling methods.

Conclusion

Up milling, while presenting certain challenges and often superseded by climb milling, retains its utility for specific machining tasks, particularly when its unique characteristics are understood and appropriately leveraged.

-

This link will help you understand the differences and when to choose climb milling over up milling for optimal results. ↩

-

Detailed Comparison of Investment Casting vs. Sand Casting Processes ↩

-

Discover the importance of rigid clamping in up milling to ensure precision and prevent workpiece movement during machining. ↩

-

Discover how backlash eliminators enhance precision in CNC machines, crucial for achieving high-quality results in industrial automation. ↩

-

Understanding machining strategy is crucial for optimizing milling operations and improving efficiency. Explore this link to deepen your knowledge. ↩

-

Knowing the differences between these tools can enhance your machining projects. Click to learn more about their unique applications. ↩