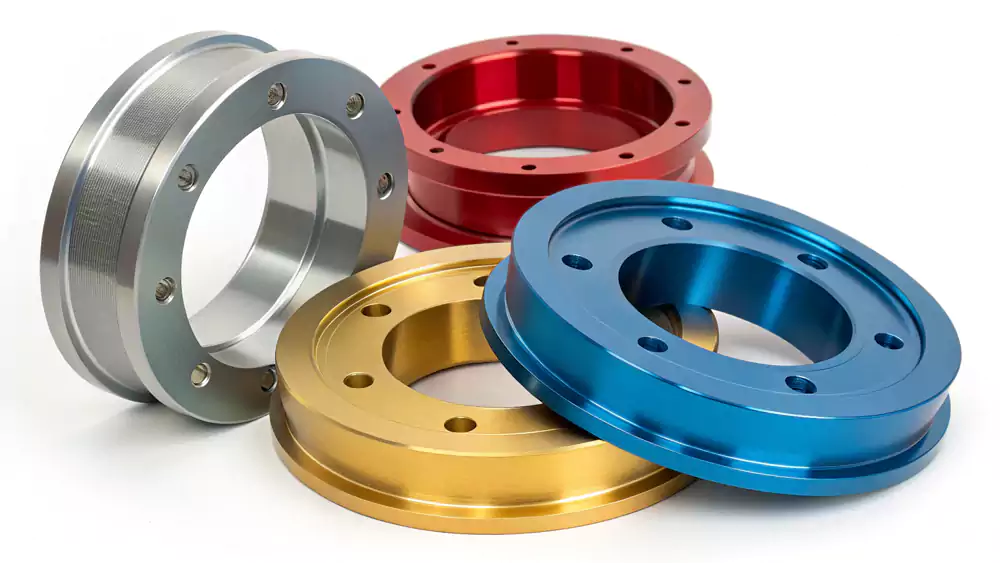

Balancing Aesthetics and Performance: A Buyer’s Guide to Surface Finishes for Motorcycle Fasteners?

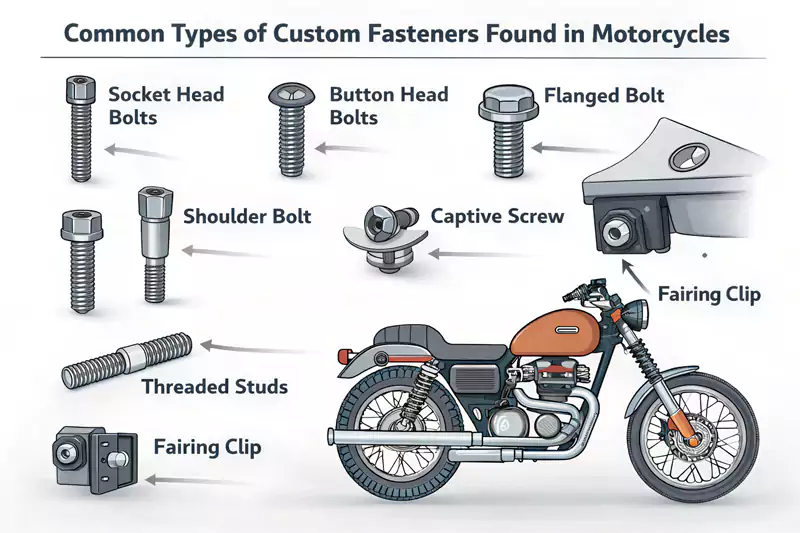

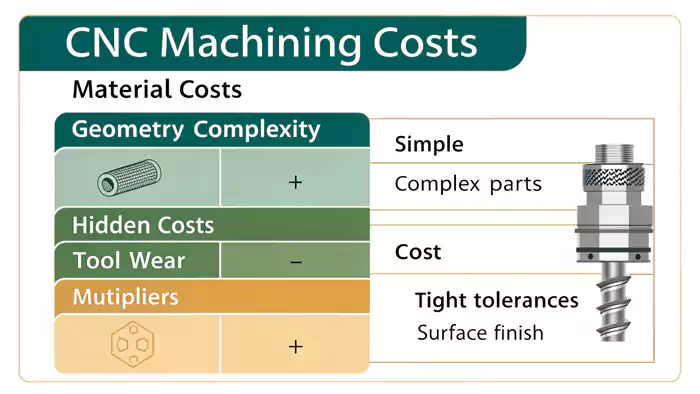

This guide helps procurement teams balance aesthetics, performance, and cost when selecting surface finishes for motorcycle fasteners. It explains key risks, business scenarios, and how early specification and the right supplier reduce sourcing issues.