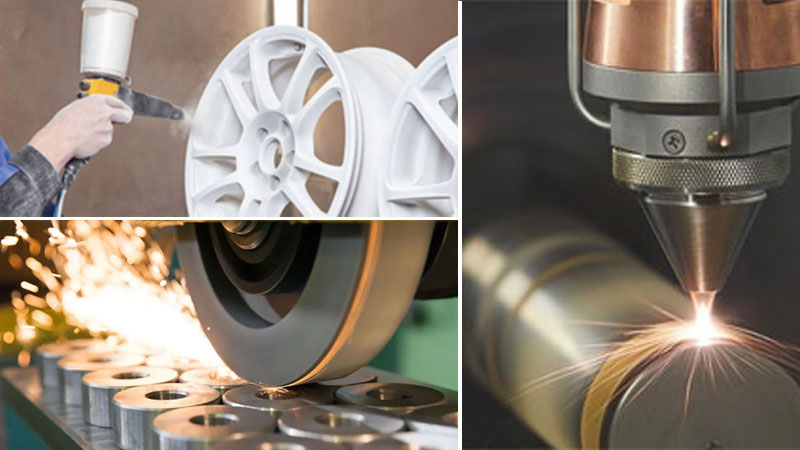

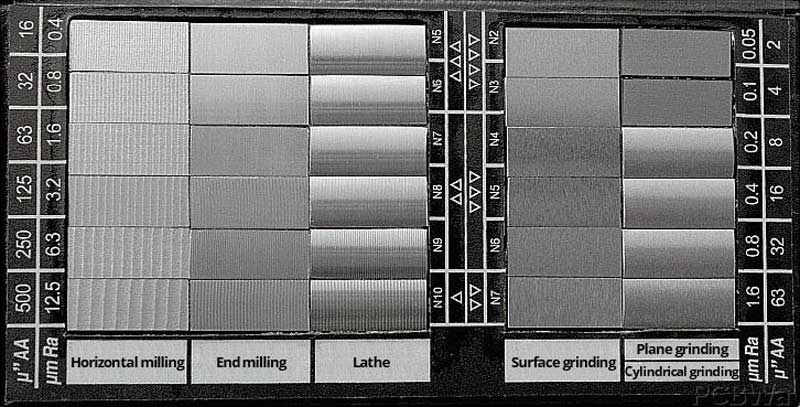

Surface treatment in CNC machining

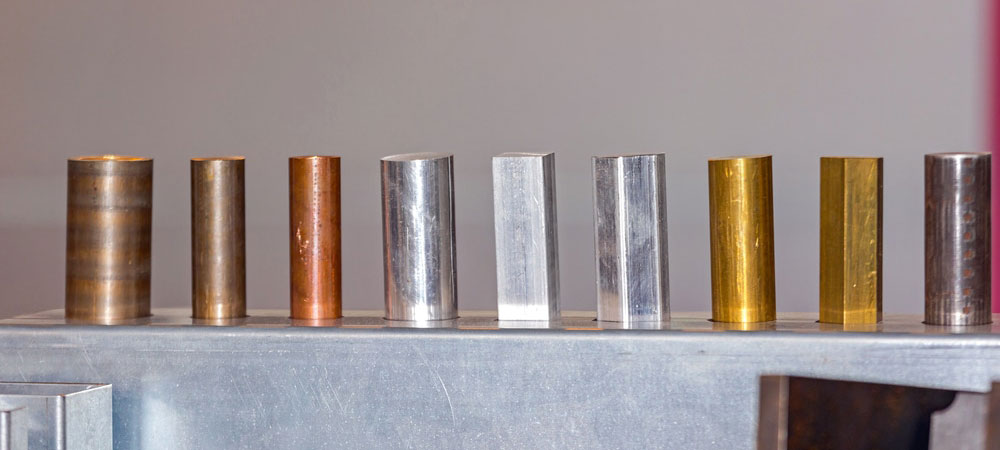

In CNC machining, surface treatment improves a part’s performance and appearance. It enhances wear resistance, corrosion resistance, strength, and heat resistance. This article explains common surface treatments and how they extend a part’s lifespan.